Closed strip-shaped coal yard monitoring device

A monitoring device and coal yard technology, applied in measuring devices, optical devices, heat measurement, etc., can solve the problems of inaccurate coal measurement and large power consumption of bucket wheel machines, and reduce the use of electronic control components or power components , High accuracy of mechanical linkage, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in more detail below in conjunction with examples.

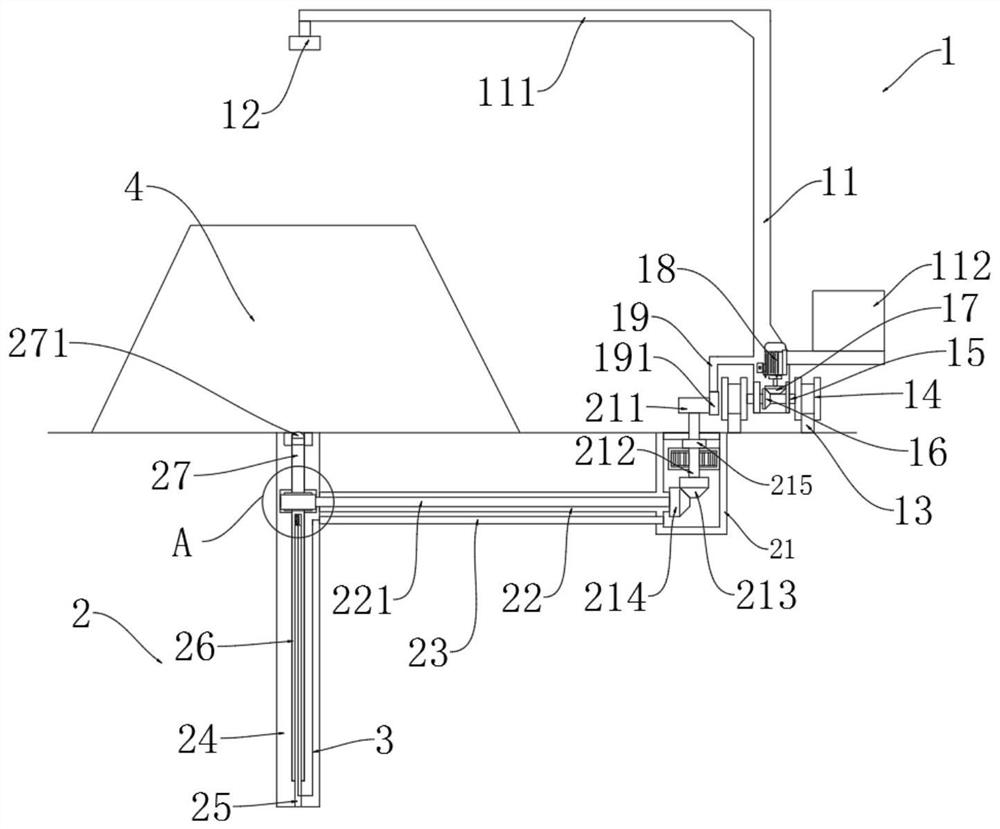

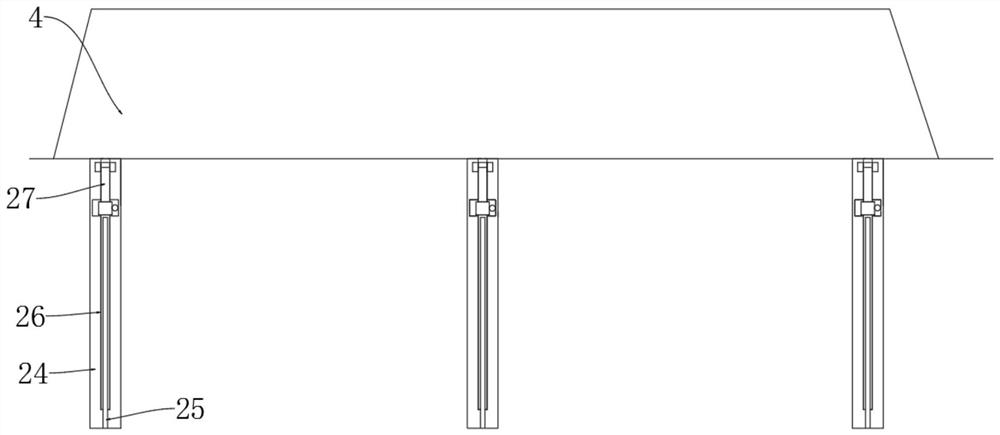

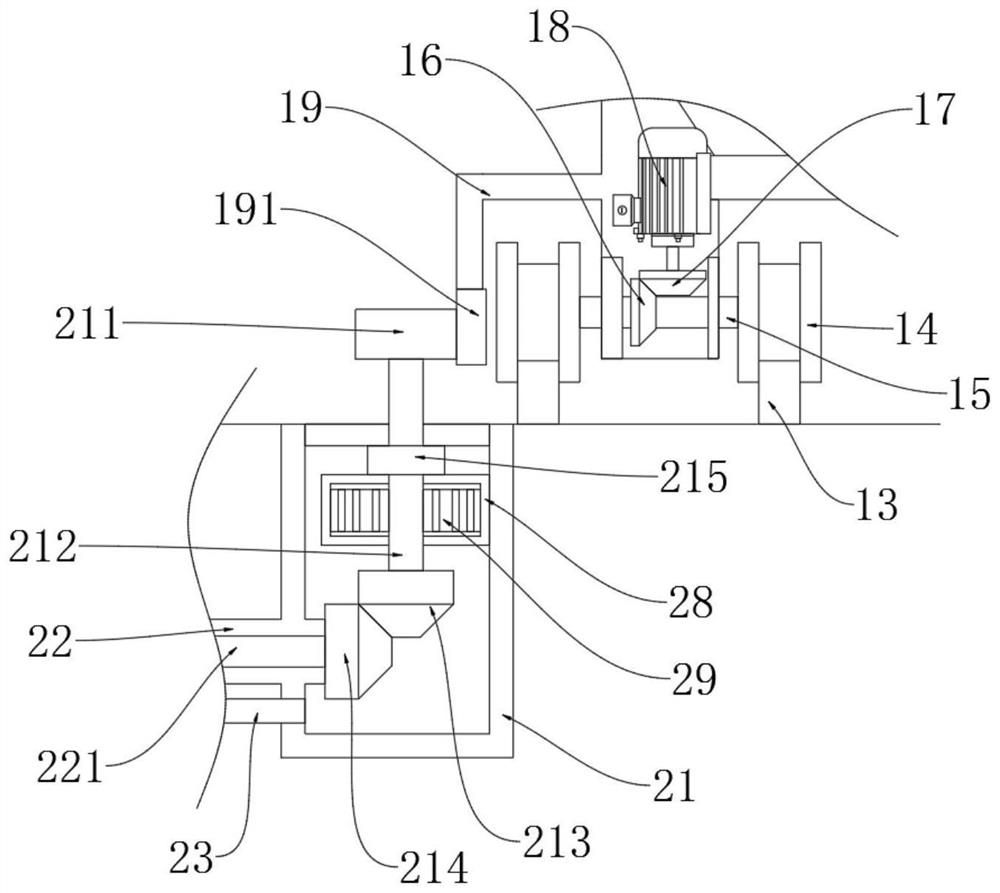

[0033] Such as Figures 1 to 6 As shown, the closed strip coal yard monitoring device of the present embodiment includes a coal pan device 1 arranged on the side edge of the coal pile 4 and a temperature detection device 2 buried in the ground below the coal pile 4, and the coal pan device 1 includes an installation A frame 11, a laser coal measuring instrument 12 and a pair of mutually parallel rails 13 fixed on the ground and arranged along the length direction of the coal pile 4, a power motor 18 is fixed on the mounting frame 11, and the output shaft of the power motor 18 is fixedly socketed There is a powered bevel gear 17; the bottom end of the mounting frame 11 is fixed with an axle 15, and the two ends of the axle 15 are fixedly sleeved with sliding wheels 14, and the two sliding wheels 14 are respectively connected with two rails 13 in a rolling manner. There is a shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com