Ultrasonic automatic detection equipment

An automatic detection and ultrasonic technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, use sound waves/ultrasonic waves/infrasonic waves for material analysis, and measurement devices, etc. It can solve the problem that the stability of product detection cannot be guaranteed and cannot meet mass testing. Industrial requirements, low detection efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

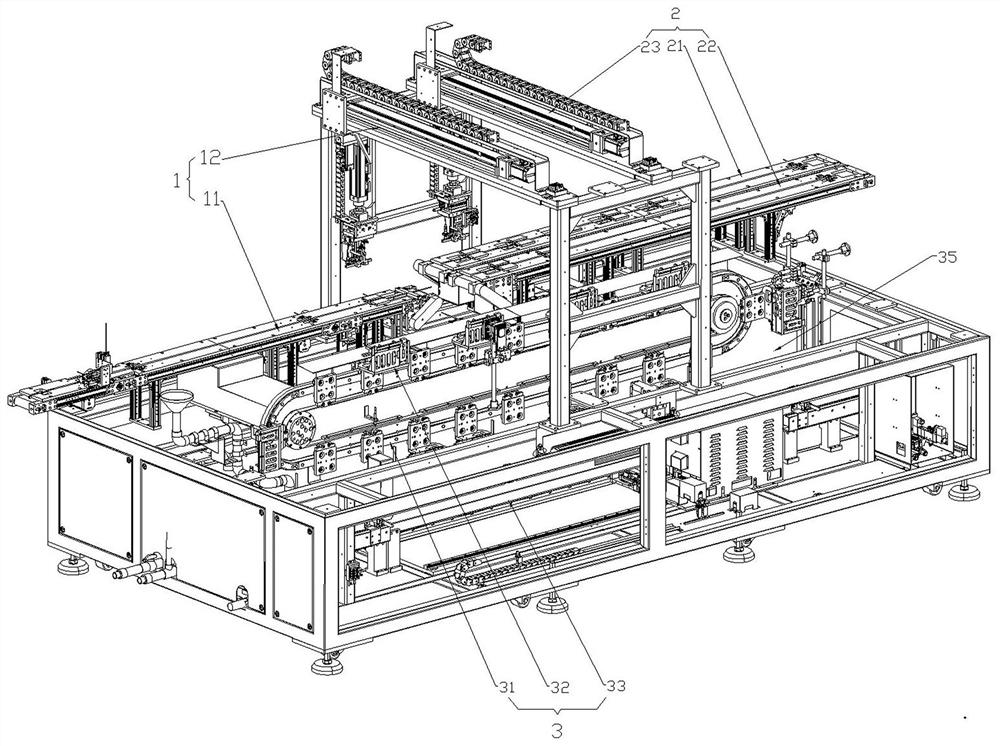

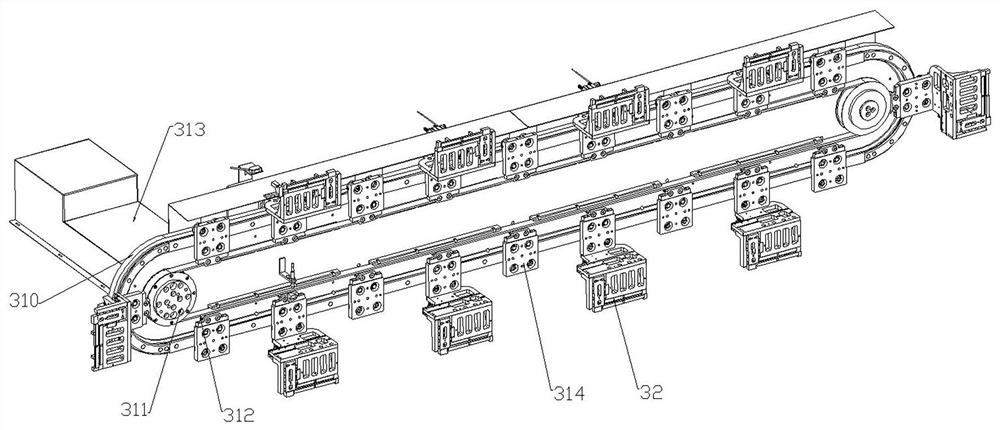

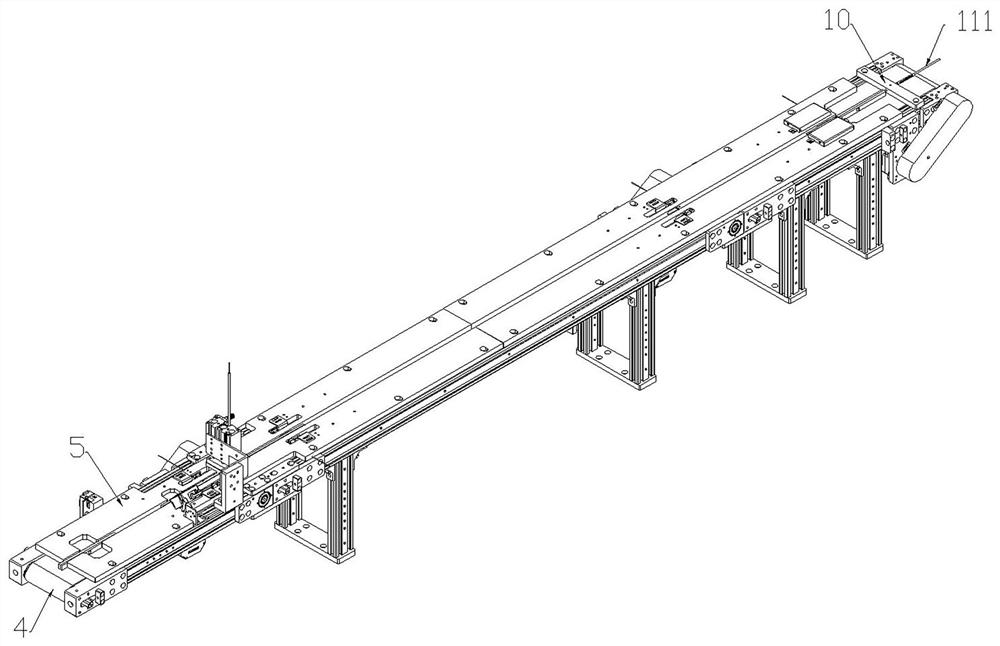

[0031] like Figure 1 to Figure 6As shown, in this embodiment, the present invention includes a material feeding module 1, a material discharging module 2 and a detection module 3, and the material feeding module 1 and the material discharging module 2 are respectively arranged at the input ends of the detection module 3 and the output end, the feeding module 1 includes a first conveying line 11, a first manipulator assembly 12 is arranged above the first conveying line 11, and the discharging module 2 includes a second conveying line 21 and a third conveying line 11. Line 22, the second manipulator assembly 23 is arranged above the second conveying line 21 and the third conveying line 22, the detection module 3 includes a circular transport mechanism 31, and the action end of the circular transport mechanism 31 is provided with Several grippers 32, the first manipulator assembly 12 and the second manipulator assembly 23 are all matched with the grippers 32, a first linear mod...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap