PCB and processing method thereof

A processing method and sub-board technology are applied in the direction of multilayer circuit manufacturing, electrical connection of printed components, and structural connection of printed circuits, which can solve the problems of large aperture ratio, process complexity, high production cost, and large thickness. Small aperture ratio, reduce process complexity and production cost, and avoid the effect of excessive aperture ratio

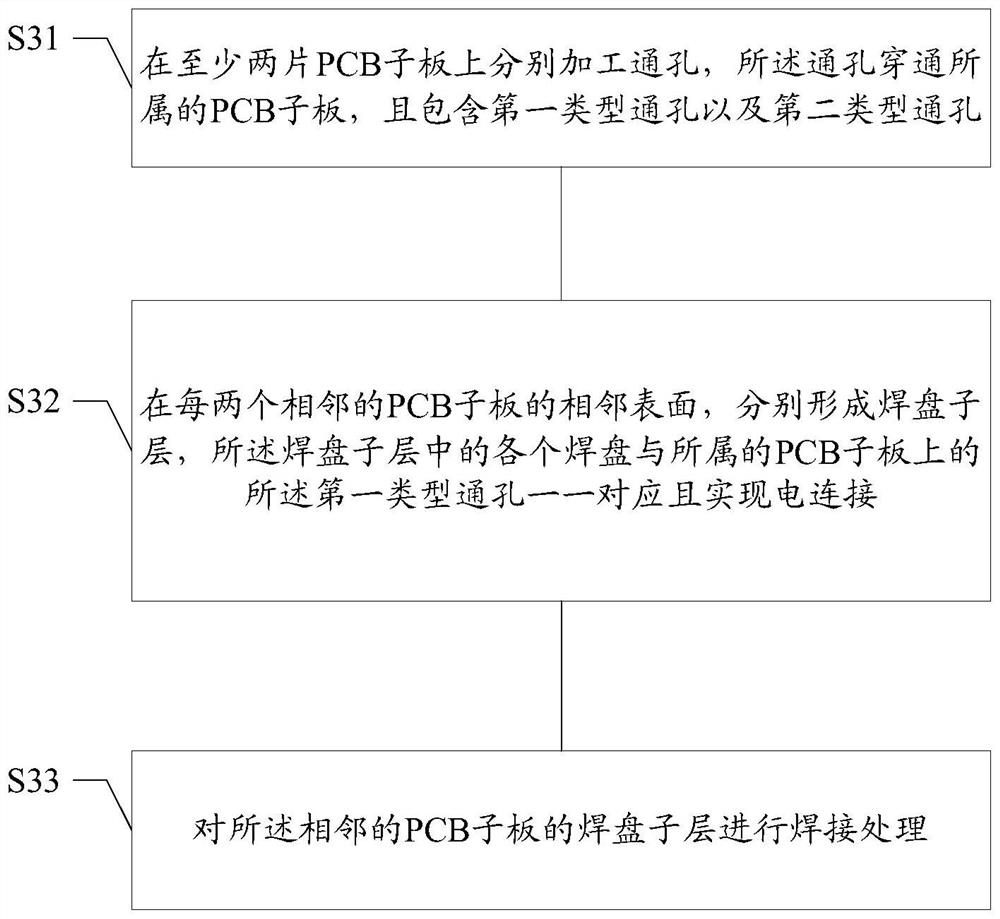

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the prior art, as the diameter of the PCB hole becomes smaller and smaller, the laminated PCB has more layers and a larger thickness, resulting in a very large aperture ratio, increasing process complexity and production costs. Difficult to meet user needs.

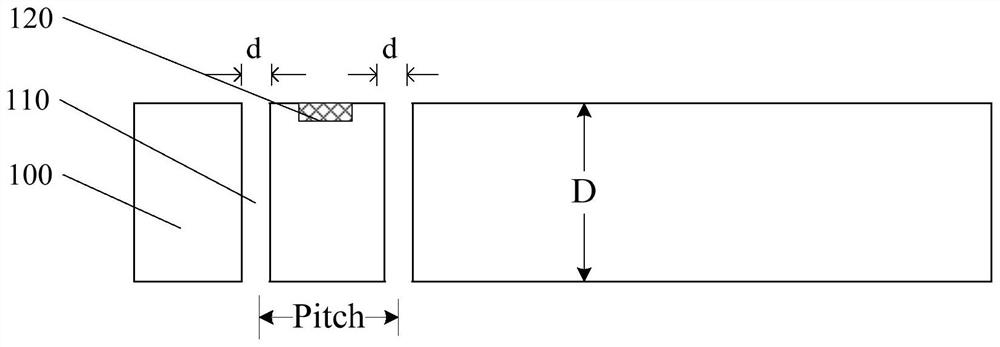

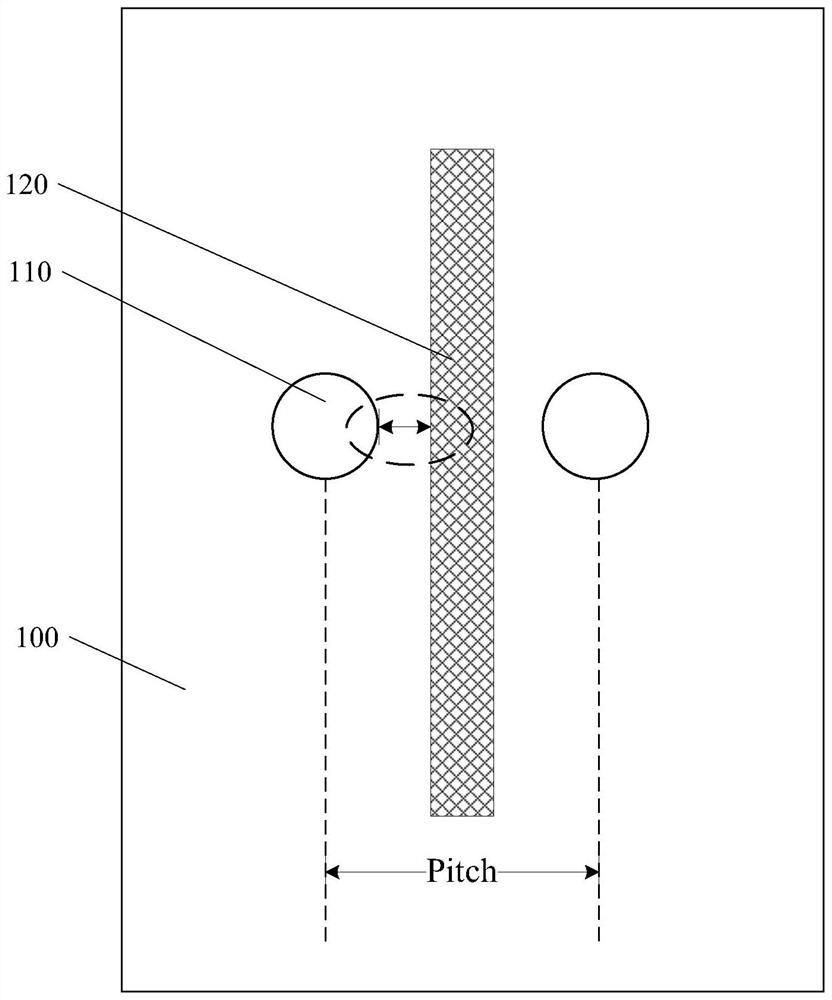

[0031] combined reference figure 1 and figure 2 , figure 1 is a schematic cross-sectional structure diagram of a PCB in the prior art, figure 2 It is a top view of a PCB in the prior art.

[0032] specifically, figure 1 The thickness of the PCB 100 shown is D, and a through hole 110 is processed on the PCB 100, the diameter of the through hole 110 is d.

[0033] It can be understood that as D becomes larger and d becomes smaller, the ratio of D to d (that is, the aperture ratio) also becomes larger.

[0034] Since in the PCB 100, it is necessary to reserve enough space between the through holes 100 to form the metal lines 120, it is necessary to limit the distance between the through holes 100, for examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com