A kind of processing method and equipment of anthocyanin-rich fried potato chips

A technology of fried potato chips and a processing method, which is applied in the directions of food processing, oil/fat roasting, food heat treatment, etc., can solve the problem of difficulty in retaining anthocyanins and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Processing method of potato chips

[0034] The invention discloses a processing method for anthocyanin-rich fried potato chips, which specifically comprises the following steps:

[0035] (1) After peeling the potatoes, soak them in running water for 4 to 6 hours, then cut them into potato slices with a thickness of 0.1 to 0.3 cm, and wash the potato slices to remove starch.

[0036] (2) Blanching: Blanch the potato chips at 95-96°C for 4-6min, 96°C is the boiling point of water in a high-altitude area with an altitude of 2km. Therefore, the processing of potato chips according to the present invention can be carried out at high altitudes. The preferred method is: blanching at 96°C for 4 to 6 minutes, the potato chips have just broken, but the sugar and impurities flow out. During blanching, water is fed from the water inlet and water is discharged from the water outlet, so that the water flow maintains a one-way operation process. Thereby, the sugar content ...

Embodiment 2

[0041] Embodiment 2 Detection of anthocyanin content

[0042] Cut the peeled purple potatoes into potato slices with the same thickness, wash them and dry them at room temperature. Divide the potato slices into equal weight portions, each 100g, and dry 100g of the potato slices at 60°C until Constant weight; after crushing, pass through a 60-mesh sieve until all the potato flour can pass through the mesh sieve, and store in the dark for later use.

[0043]Add 50 mL of extractant (a mixture of 1% HCl and ethanol, the volume ratio of HCl and ethanol is 40:60) to the potato flour, take it out in a constant temperature water bath at 60°C for 20 minutes, take it out, cool it on ice, and crush it with an ultrasonic crusher for 2 minutes (Intensity 38%, 5s, 5s); after crushing, carry out a constant temperature water bath at 60°C for 10min, then put it in a centrifuge, and centrifuge at 5000rpm for 10min to obtain a clear supernatant; take 2mL of the supernatant and dilute to 20mL, a...

Embodiment 3

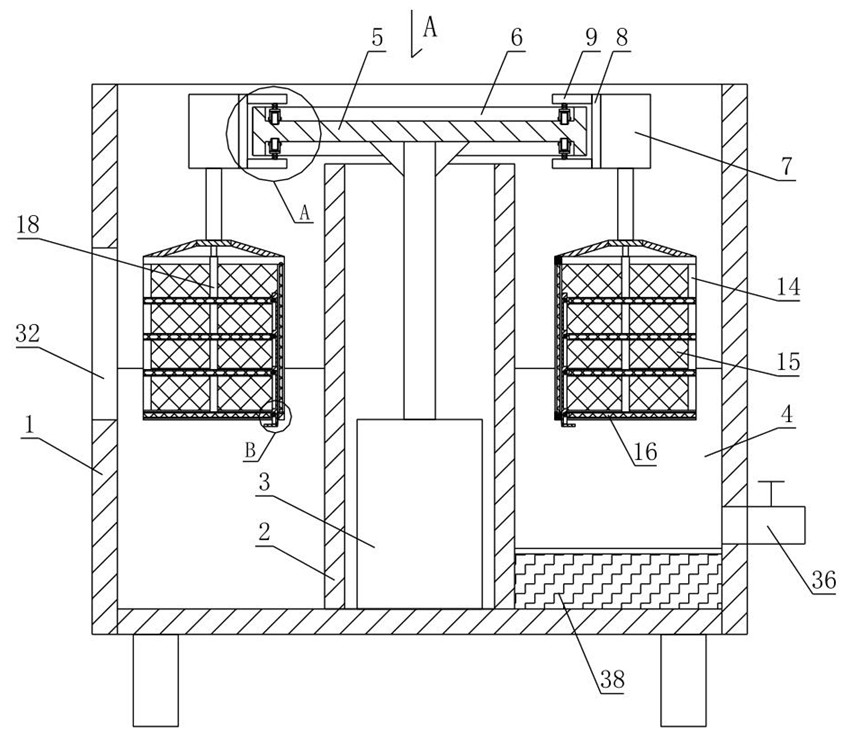

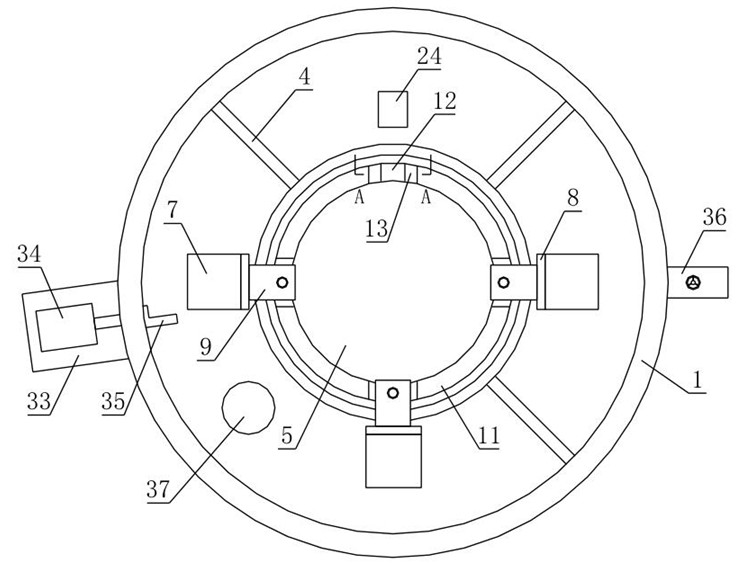

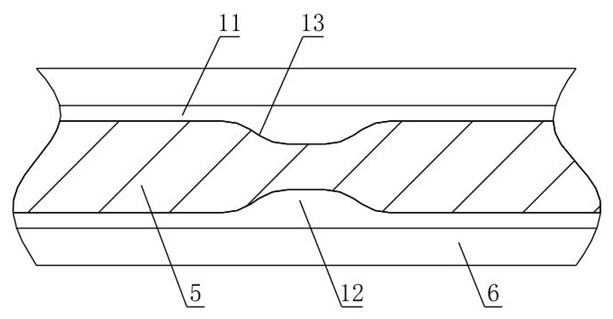

[0053] Example 3 Potato Chip Processing Device

[0054] refer to Figure 1-Figure 9 , the present invention discloses a processing device for fried potato chips rich in anthocyanin, including a frying rotary device, the frying rotary device comprises a fixed cylinder 1 with an opening at the top, and the inner center of the fixed cylinder 1 is provided with a top-opening The support cylinder 2, the height of the support cylinder 2 is lower than the height of the fixed cylinder 1, the motor 3 is arranged in the support cylinder 2, the output shaft of the motor 3 is set upward, and the output rod of the motor 3 extends out of the support cylinder 2 and is fixed with a The rotating mechanism is slidably connected with several placement components; the fixed cylinder 1 is provided with several partitions 4 , and the placement components correspond to the area enclosed by the adjacent partitions 4 . The partition 4 is arranged in the annular area formed between the fixed cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com