Concrete pavement crushing treatment integrated system

A concrete pavement and crushing machine technology, applied in grain processing, roads, roads, etc., can solve the problems that crushed stones cannot be used directly, crushed stones cannot be collected, and crushed stones cannot be collected by classification, so as to prolong the residence time and improve the screening Effect, effect to improve functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

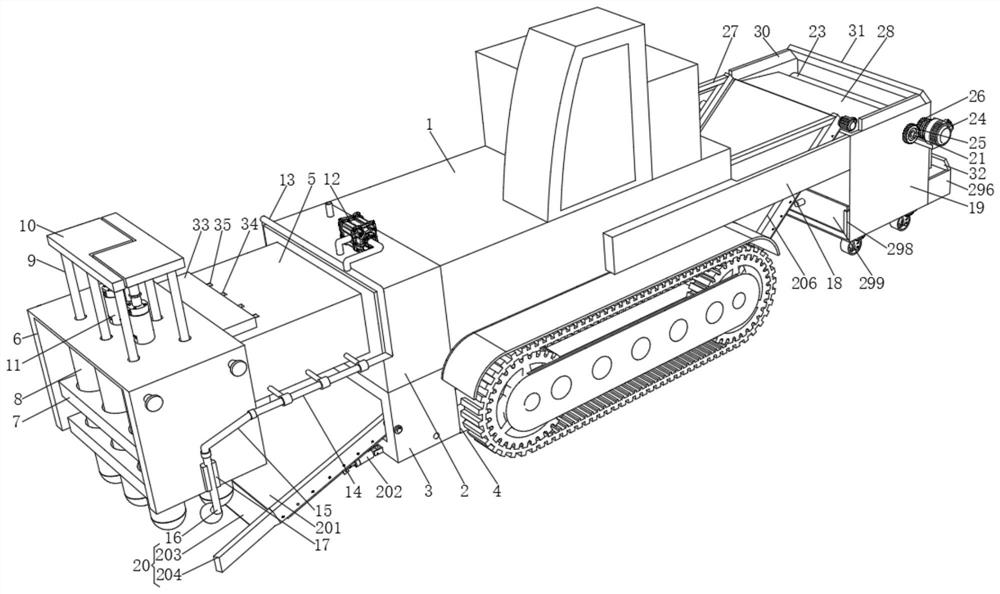

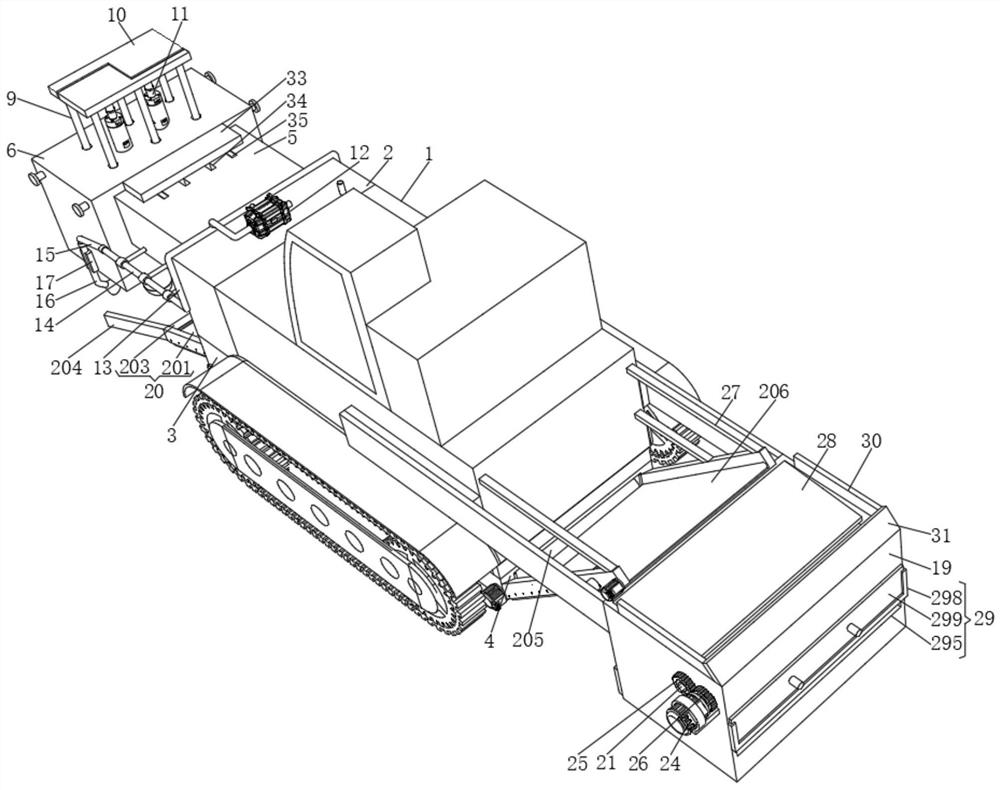

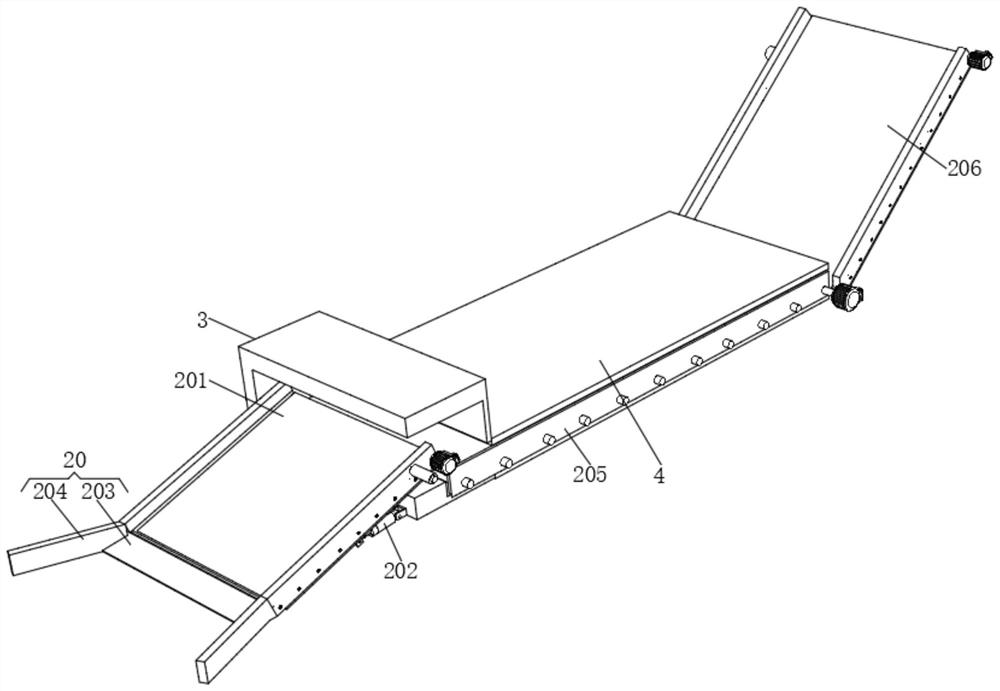

[0034] Such as Figure 1-6 The integrated system for concrete pavement crushing and treatment shown includes a pavement crusher body 1, a water tank 2 is fixedly connected to the top of one side of the road crusher body 1, a fixed frame 3 is fixedly connected to the bottom of the water tank 2, and the fixed frame 3 One side is fixedly connected to the road crusher body 1, the bottom of one side of the fixed frame 3 is fixedly connected with a support frame 4 and the support frame 4 is located at the bottom of the road crusher body 1, and the top side of the support frame 4 is fixedly connected through a connecting plate At the bottom of the road breaker body 1, the front and back of the road breaker body 1 are fixedly connected with a support plate 18, one side of the support plate 18 is fixedly connected with a box body 19, and the four sides of the bottom of the box body 19 are provided with universal The wheels can assist the movement of the box body 19 and support the box ...

Embodiment 2

[0045] This embodiment is a further improvement of the previous embodiment, such as Figure 1-6 As shown, an integrated system for concrete pavement crushing and treatment includes a pavement crusher body 1, a water tank 2 is fixedly connected to the top of one side of the road crusher body 1, a fixed frame 3 is fixedly connected to the bottom of the water tank 2 and the fixed frame 3 One side is fixedly connected to the road crusher body 1, the bottom of one side of the fixed frame 3 is fixedly connected with a support frame 4 and the support frame 4 is located at the bottom of the road crusher body 1, and the top side of the support frame 4 is fixedly connected through a connecting plate At the bottom of the road breaker body 1, the front and back of the road breaker body 1 are fixedly connected with a support plate 18, one side of the support plate 18 is fixedly connected with a box body 19, and the four sides of the bottom of the box body 19 are provided with universal The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com