Pipeline hot melting welding machine

A technology for hot-melt welding machines and pipes, which is applied to tubular objects, other household appliances, household appliances, etc., can solve the problems of wasting manpower, and achieve the effects of convenient operation, labor cost saving, and high welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is attached Figure 1-4 The application is described in further detail.

[0032] The embodiment of the present application discloses a pipeline heat fusion welding machine.

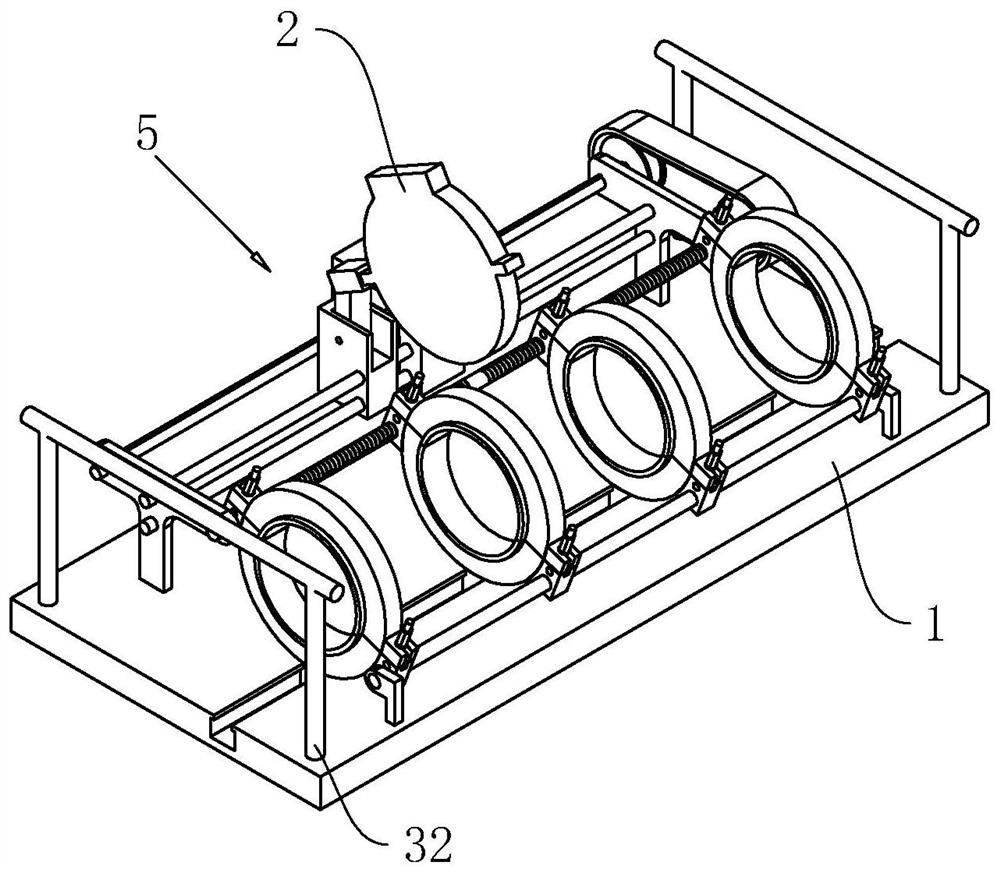

[0033] refer to figure 1 , a pipe hot-melt welding machine, including a mounting base 1, handles 32 are fixed on the outer walls of both ends of the mounting base 1, the staff can lift the entire mounting base 1 by lifting the handle 32, thereby realizing the mobile mounting base 1 position.

[0034] refer to figure 1 A heating plate 2 is arranged on the mounting seat 1, the heating plate 2 is a resistance plate, and an insulating and heat-conducting material, such as heat-conducting silicone grease, is formed on the outside of the heating plate 2. The resistance inside the heating plate 2 is set in communication with the external electrical circuit through the wire, so that the heating plate 2 can generate heat after being energized.

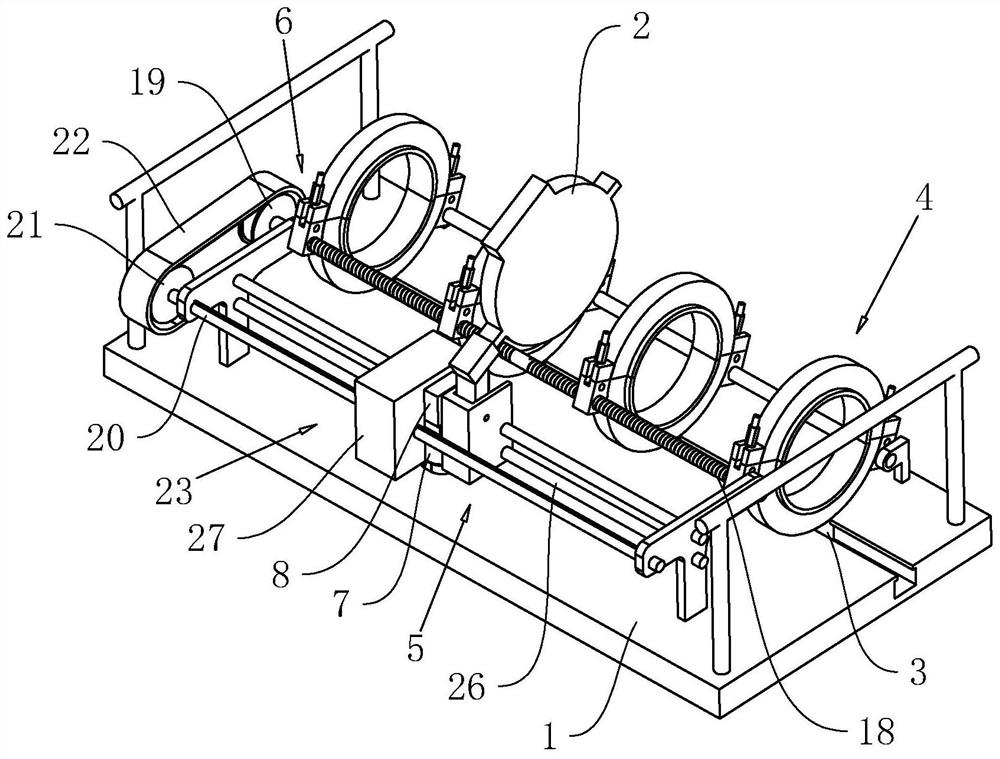

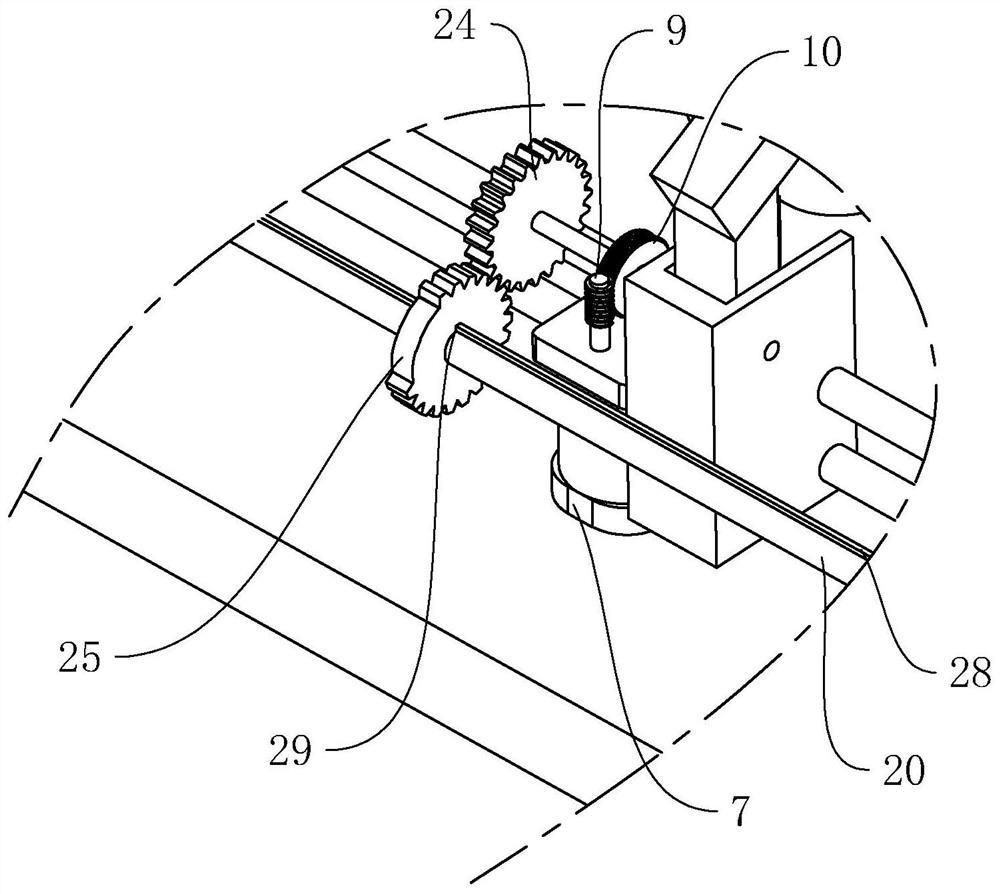

[0035] refer to figure 2 , the mounting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com