Method for desulfurizing waste tires by using supercritical carbon dioxide

A carbon dioxide and waste tire technology, applied in the field of waste tire desulfurization, can solve the problems of high density, dark color, high sulfur content, etc., and achieve the effects of simple operation, strong process controllability and simple technical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

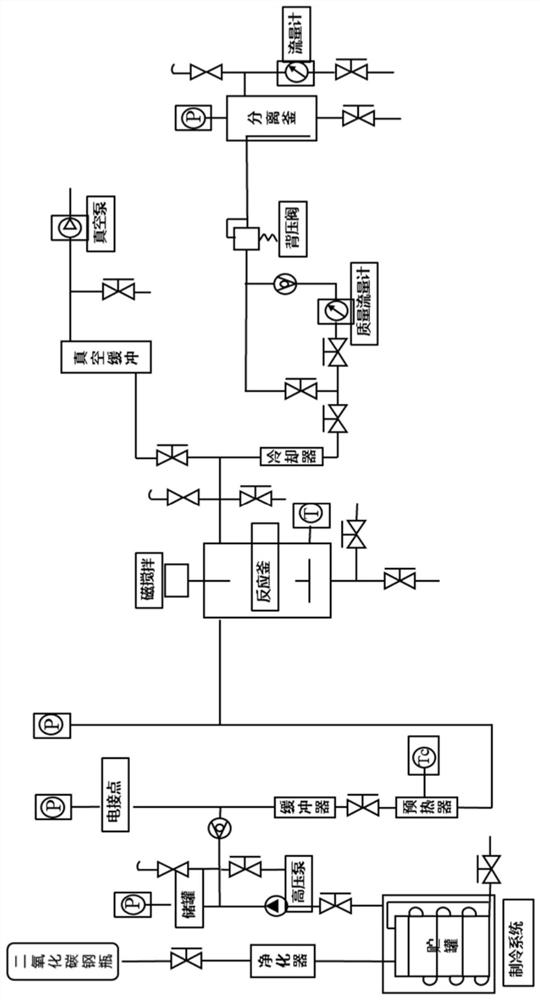

Method used

Image

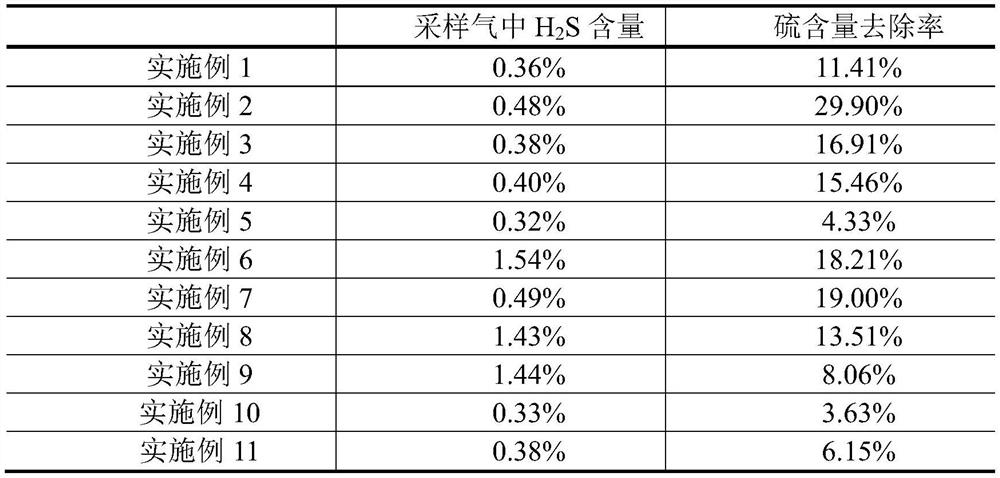

Examples

Embodiment 1

[0033] A method of supercritical carbon dioxide for use in waste tire deulfurization, the specific steps are as follows:

[0034] (1) From the waste tire to cut the tread glue, simply cleans it, then remove the surface of the tread glue into small pieces, placed in the crusher, crush the sieve, the present invention selects the particle size Tire particles of 0.55-1mm;

[0035] (2) Weigh 2G waste tire samples and 0.2 g of desulfurizing agent diphennesulfide, mix the two;

[0036] (3) Place the mixture in a supercritical carbon dioxide reaction kettle, with a vacuum pump to extract the air in the reactor, and turn off the pressure relief valve after row;

[0037] (4) Turn carbon dioxide into the reactor, the pressure of the kettle is 10 MPa, and the carbon dioxide is packed into the reaction kettle to reach the predetermined pressure value, and at the same time the temperature is 250 ° C, the temperature is 250 ° C, this temperature pressure under temperature pressure conditions In...

Embodiment 2

[0042] A method of supercritical carbon dioxide for use in waste tire deulfurization, the specific steps are as follows:

[0043] (1) From the waste tire to cut the tread glue, simply cleans it, then remove the surface of the tread glue into small pieces, placed in the crusher, crush the sieve, the present invention selects the particle size Tire particles of 0.55-1mm;

[0044] (2) Weigh 2G waste tire samples and 0.2 g of desulfurizing agent diphennesulfide, mix the two;

[0045] (3) Place the mixture in a supercritical carbon dioxide reaction kettle, with a vacuum pump to extract the air in the reactor, and turn off the pressure relief valve after row;

[0046](4) Carbon dioxide in the reactor, the pressure of the kettle is 10 MPa, and the carbon dioxide is packed into the reaction kettle to reach the predetermined pressure value, and the temperature is 1050 ° C, the temperature pressure is carbon dioxide under temperature pressure. In the supercritical state;

[0047] (5) The re...

Embodiment 3

[0051] A method of supercritical carbon dioxide for use in waste tire deulfurization, the specific steps are as follows:

[0052] (1) From the waste tire to cut the tread glue, simply cleans it, then remove the surface of the tread glue into small pieces, placed in the crusher, crush the sieve, the present invention selects the particle size Tire particles of 0.55-1mm;

[0053] (2) Weigh 2G waste tire samples and 0.2 g of desulfurizing agent diphennesulfide, mix the two;

[0054] (3) Place the mixture in a supercritical carbon dioxide reaction kettle, with a vacuum pump to extract the air in the reactor, and turn off the pressure relief valve after row;

[0055] (4) Turn carbon dioxide into the reactor, the pressure of the kettle is 10 MPa, and the carbon dioxide is packed into the reaction kettle to reach the predetermined pressure value, and at the same time the temperature is 250 ° C, the temperature is 250 ° C, this temperature pressure under temperature pressure conditions In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com