Cleaning agent for removing printing ink sprayed codes on surface of aluminum plastic film and use method of cleaning agent

A cleaning agent and aluminum-plastic film technology, applied in the field of cleaning agents, can solve problems affecting the appearance of batteries, loss of manufacturing companies, scrapped batteries, etc., and achieve the effects of controllable operating risks, high safety attributes, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A cleaning agent for removing inkjet codes on the surface of an aluminum-plastic film, said cleaning agent comprising the following raw materials in weight percent: 70% pure water, 12% petroleum ether, 9% ethyl propionate, and 9% ethanol.

[0033] Use this cleaning agent to clean the soft-packed cells with barcodes printed on the surface of the aluminum-plastic film. The ink type used to print the barcodes is J199, and the manufacturer is Markem-Imaje. The cleaning method is as follows:

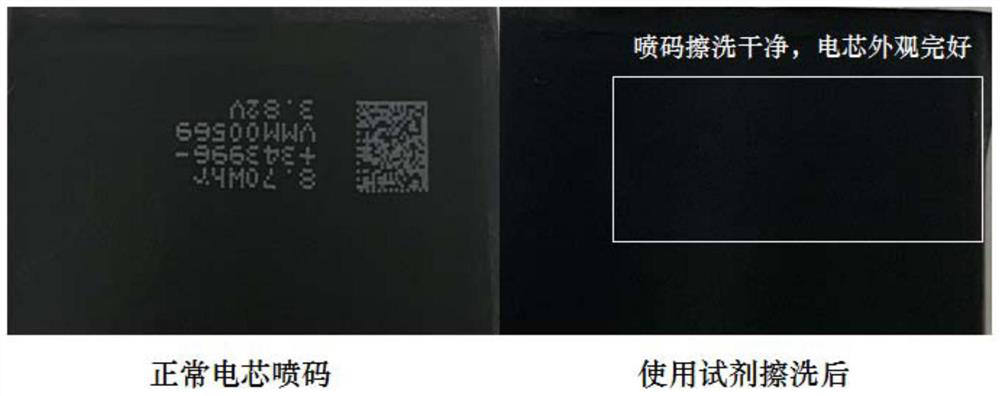

[0034] Use a dust-free paper dipped in the scrubbing reagent, and gently wipe the coded area of the soft-packed battery; observe the state of the coded area of the soft-packed battery in a bright place, and the un-coded area on the surface of the battery and the coded area before scrubbing For comparison, the result is as figure 1 As shown, it can be clearly seen from the figure that there is no inkjet residue on the surface of the battery cell after being wiped by the cleaning age...

Embodiment 2

[0036] A cleaning agent for removing inkjet coding on the surface of an aluminum-plastic film. The cleaning agent includes the following raw materials in weight percent: 65% pure water, 15% acetone, 10% dimethyl carbonate, and 10% ethanol.

[0037] Use this cleaning agent to clean the soft pack batteries with barcodes printed on the surface of the aluminum-plastic film. The ink type used to print the barcodes is MW133, and the manufacturer is Markem-Imaje. The cleaning method is as follows:

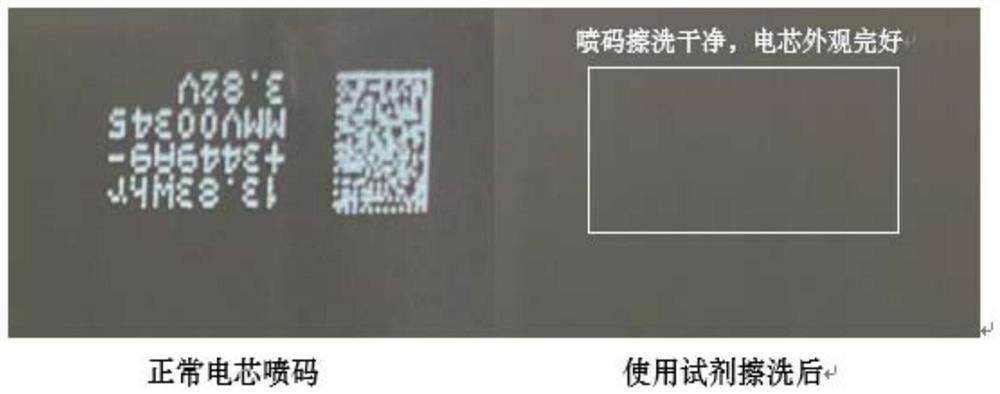

[0038] Use a dust-free paper dipped in the scrubbing reagent, and gently wipe the coded area of the soft-packed battery; observe the state of the coded area of the soft-packed battery in a bright place, and the un-coded area on the surface of the battery and the coded area before scrubbing For comparison, the result is as figure 2 As shown, it can be clearly seen from the figure that there is no inkjet residue on the surface of the battery cell after being wiped by the cleaning agent...

Embodiment 3

[0040] A cleaning agent for removing inkjet coding on the surface of an aluminum-plastic film. The cleaning agent includes the following raw materials in weight percent: 68% pure water, 7% acetonitrile, 10% ethyl propionate, and 15% ethanol.

[0041] Use this cleaning agent to clean the soft-packed batteries with barcodes printed on the surface of the aluminum-plastic film. The ink type used to print the barcodes is MB175, and the manufacturer is Markem-Imaje. The cleaning method is as follows:

[0042] Use a dust-free paper dipped in the scrubbing reagent, and gently wipe the coded area of the soft-packed battery; observe the state of the coded area of the soft-packed battery in a bright place, and the un-coded area on the surface of the battery and the coded area before scrubbing For comparison, the result is as image 3 As shown, it can be clearly seen from the figure that there is no inkjet residue on the surface of the battery cell after being wiped by the cleaning ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com