Copper scrap recovery device and device

A recovery device and technology of copper filings, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems affecting the separation effect, weakening of magnetic force, inclusion of copper filings, etc., to improve practicability, facilitate pressing and forming, The effect of reducing the magnetic requirements for adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

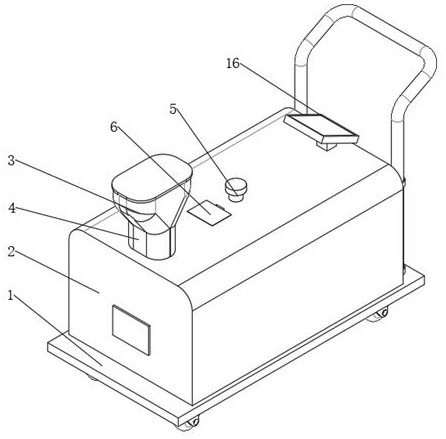

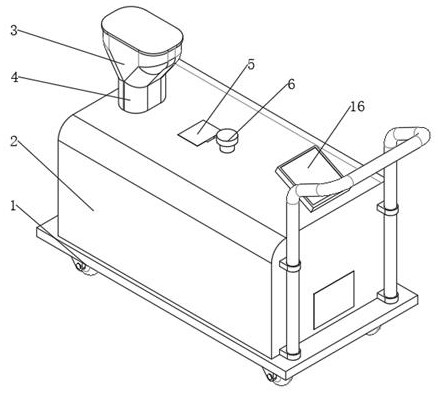

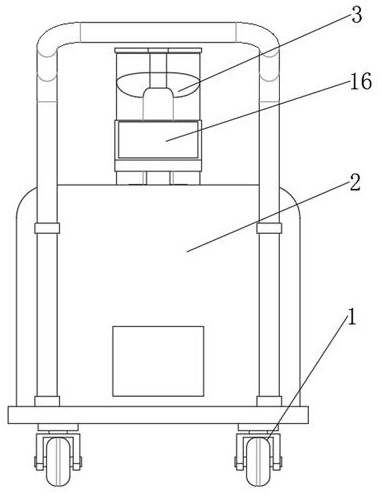

[0037] Such as Figure 1-4 As shown, the embodiment of the present invention provides a copper shavings recovery device, including a mobile chassis 1 and a housing 2, the upper part of the mobile chassis 1 is fixedly connected to the housing 2, and the middle part of the upper end of the housing 2 is provided with a feed pipe 4, The top of the feeding pipe 4 is fixedly connected with the feeding hopper 3, and the position corresponding to the feeding pipe 4 is fixedly connected with the roller shaft feeder 7 above the inside of the housing 2, and the bottom of the roller shaft feeder 7 is provided with Iron filings removal mechanism 8, a weighing trough 11 is arranged below the iron filings removal mechanism 8, and the iron filings removal mechanism 8 includes a feeding channel 801, a material distribution plate 802, a magnetic rolling belt 803, an electric roller brush 804 and a rotating The plate 805, the top of the feeding channel 801 is fixedly connected with the roller bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com