Shield segment repairing system and method

A technology of shield segment and repair production line, which is applied in the field of shield segment repair system, can solve the problems that the side of the shield segment cannot be repaired in time, affects the repair efficiency of the shield segment, and the number of cranes is limited, etc. Achieve the effect of improving convenience, compact structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

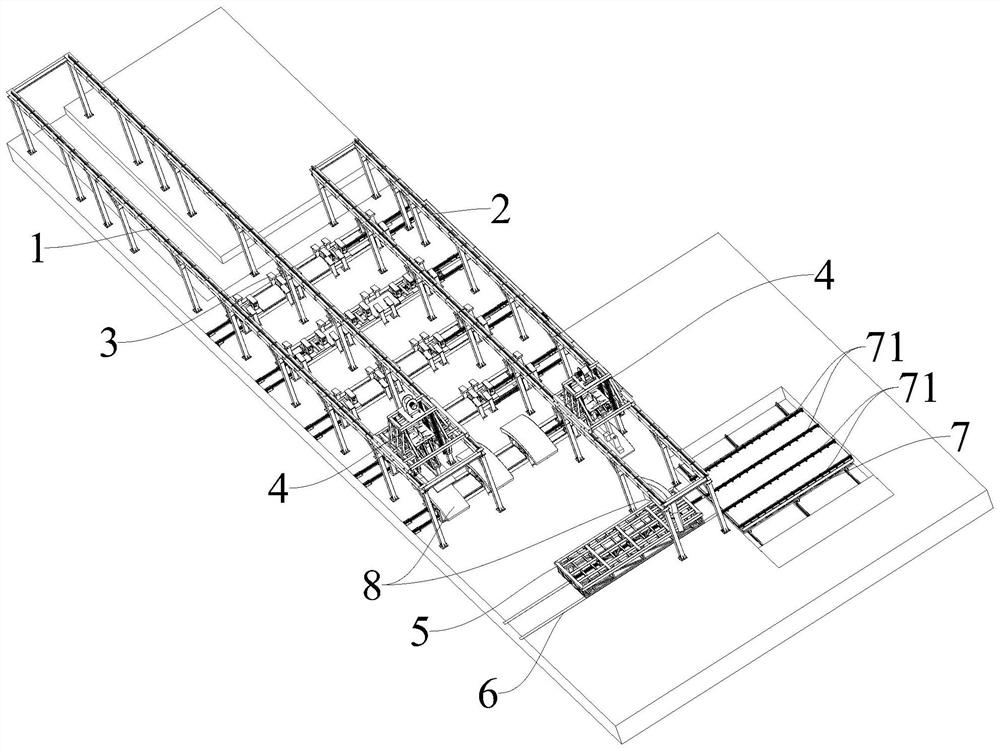

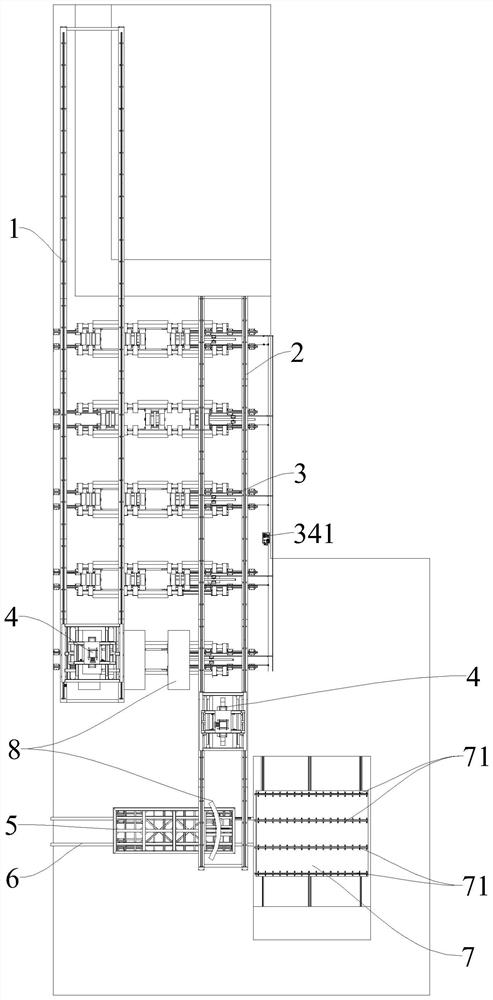

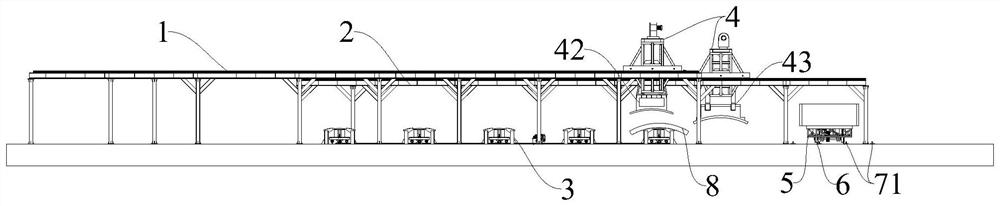

[0065] Such as Figure 1-Figure 3 As shown, a shield segment repair system of the present invention includes truss one 1, truss two 2 and repair production line 3, both truss one 1 and truss two 2 are equipped with a transport trolley 4, and the transport trolley 4 is used to transport the shield The construction segment 8, the conveying trolley 4 is provided with a fixing device, and the fixing device is used to fix the shield segment 8;

[0066]The repair production line 3 includes a plurality of support frames 31 and a transfer mechanism. The plurality of support frames 31 are arranged at intervals to form a production line. The support frames 31 are used to hold the inner arc surface of the shield segment 8. The transfer mechanism can support The shield segment 8 is transferred between the frames 31, the transport trolley 4 can slide along the truss one 1 to the support frame 31 at the head end of the repair production line 3, and the transport trolley 4 can slide along th...

Embodiment 2

[0081] A kind of shield tunneling segment 8 repairing method of the present invention uses a kind of shield tunneling segment 8 repairing system as described in embodiment 1, comprises the following steps:

[0082] A. Control the delivery trolley 4 of the truss-1 to move to the shield segment stripping area, and use the segment suction cup machine 42 to perform the stripping operation;

[0083] B. The conveying trolley 4 of the control truss-1 transfers the shield segment 8 after demoulding and places it on the support frame 31 at the head end of the repair production line 3, and completes the moving-in work of the shield segment 8 to be repaired;

[0084] C. Control the transfer trolley 33 to transfer the shield segment 8 on the support frame 31 to the adjacent support frame 31, and the workers perform inspection and repair;

[0085] D. After the shield segment 8 is repaired, continue to control the transfer trolley 33 to transfer the repaired shield segment 8 on the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com