Multi-color hand-temperature reversible thermochromic thermal transfer ribbon and preparation method thereof

A thermal discoloration, thermal transfer technology, applied in the direction of copy/marking method, temperature recording method, printing, etc., can solve the problems of limited application and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

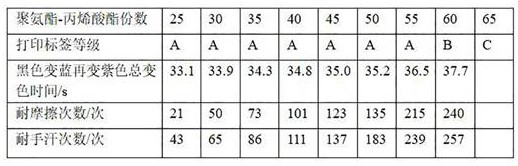

Embodiment 1

[0057] The multi-color hand temperature reversible thermochromic thermal transfer ribbon provided in this example is composed of three parts, from top to bottom: the adhesive layer coated with modified silicone, the middle layer formed by the carrier PET film layer, and the lowermost release layer, under the release layer is an ink layer formed by reversible thermochromic ink;

[0058] When the reversible thermochromic ink is specifically prepared, in terms of parts by weight, the material composition is:

[0059] 30 parts of polyurethane-acrylate composite resin emulsion;

[0060] 20 parts of thermochromic microcapsules (mass ratio, black to blue: blue to purple = 1:1);

[0061] 1 part of filler mica powder;

[0062] 0.5 parts of anti-sedimentation agent F02 dispersant;

[0063] 0.6 parts of defoamer SP-20 acetylenic diol type nonionic surfactant;

[0064] Leveling agent EL-1006 fluorosurfactant 0.8 parts;

[0065] 25 parts of water.

[0066] During concrete preparation...

Embodiment 2

[0100] The carbon ribbon product provided by the present embodiment, its preparation method is the same as embodiment 1, only adjusts as follows with respect to ink formula:

[0101] 60 parts of polyurethane-acrylate composite resin emulsion; 20 parts of thermochromic microcapsules (mass ratio, black to blue: blue to purple=1:1);

[0102] Filler mica powder 2 parts;

[0103] 0.8 parts of anti-sedimentation agent F02 dispersant;

[0104] 0.6 part of antifoaming agent acetylene glycol type nonionic surfactant;

[0105] Leveling agent EL-1006 fluorosurfactant 0.3 parts;

[0106] 37 parts of water.

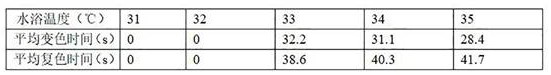

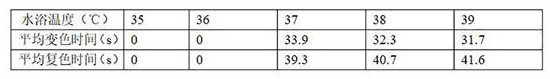

[0107] After printing the PET label with the carbon ribbon prepared in this embodiment, the detection method for the discoloration performance of the printed writing and the friction resistance and sweat resistance of the writing is the same as that of Example 1. The detection results are as follows:

[0108] The temperature from black to blue is 33°C, the color change time is 36....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com