High-pressure jet grouting pile waterproof curtain construction method

A technology of high-pressure jet grouting piles and water-stop curtains, which is applied in excavation, sheet pile walls, foundation structure engineering, etc., and can solve the problems of poor impermeability of water-stop curtains, holes or gaps of jet grouting piles, and relatively low spraying accuracy requirements. Advanced problems, achieve simple connection strength, avoid drilling collapse, and ensure the effect of generating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

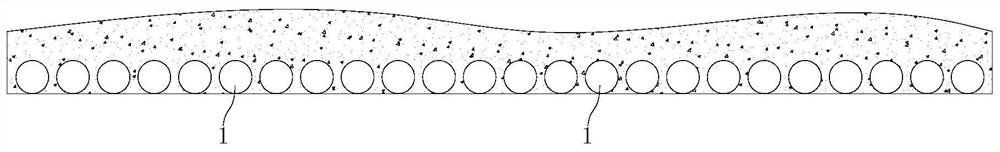

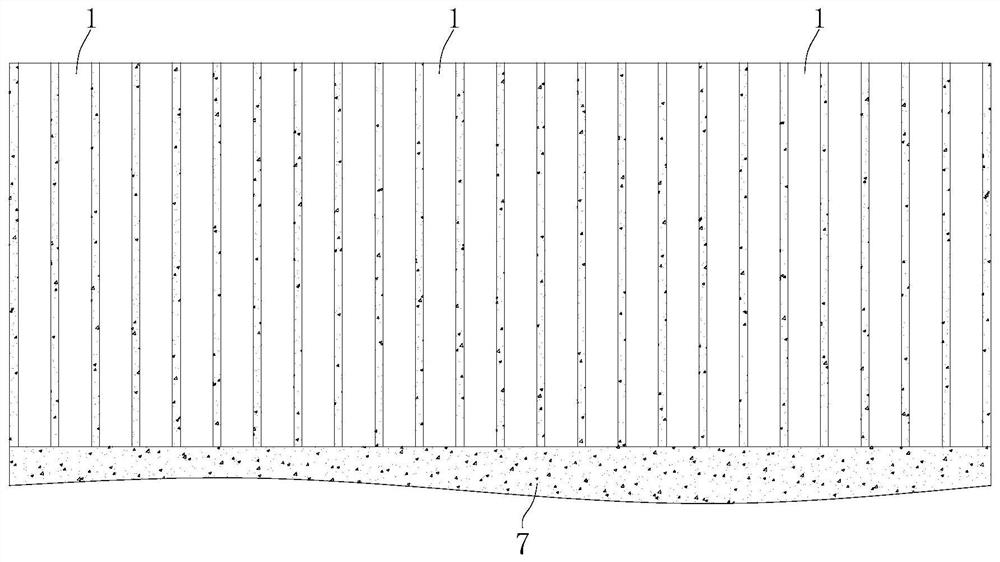

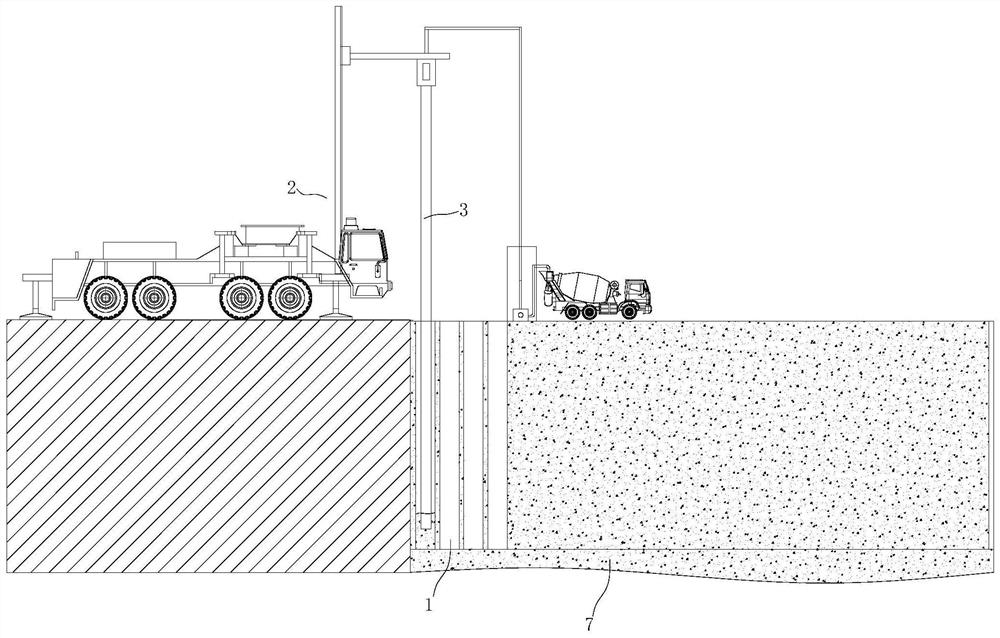

[0054] The following is attached Figure 1-11 The application is described in further detail.

[0055] The embodiment of the present application discloses a construction method for a water-stop curtain of a high-pressure rotary grouting pile. The construction method includes the following steps:

[0056] Step S1, planning of the construction area and ground cleaning: determine the area of the construction area and the rules and shapes of the construction area according to the drawings, draw a line on the edge of the construction area through the paint, and the marking line of the paint is the construction line of the high-pressure rotary grouting pile. The area surrounded by the middle of the rotary grouting pile construction line is the construction area, and the debris on the land in the construction area should be cleaned to ensure that the construction area is empty and clean.

[0057] Step S2. Drill pilot holes on the construction route of high-pressure jet grouting pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com