Half-etching equipment for integrated circuit lead frame

A lead frame and integrated circuit technology, applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as slow efficiency, unclean development, deep etching depth, etc., and achieve the effect of preventing rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

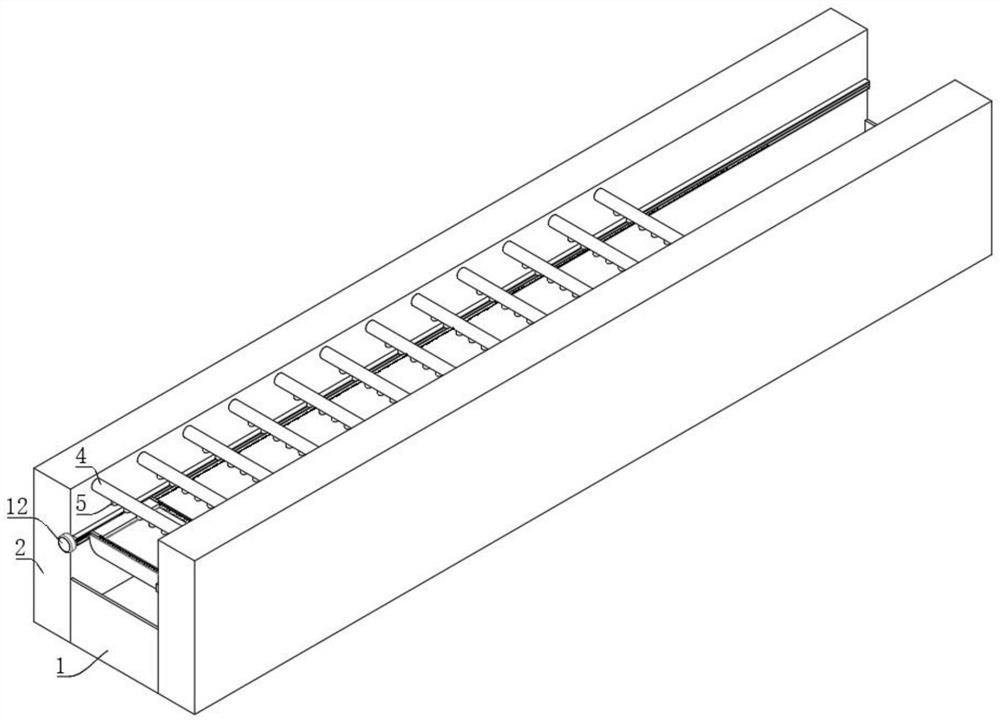

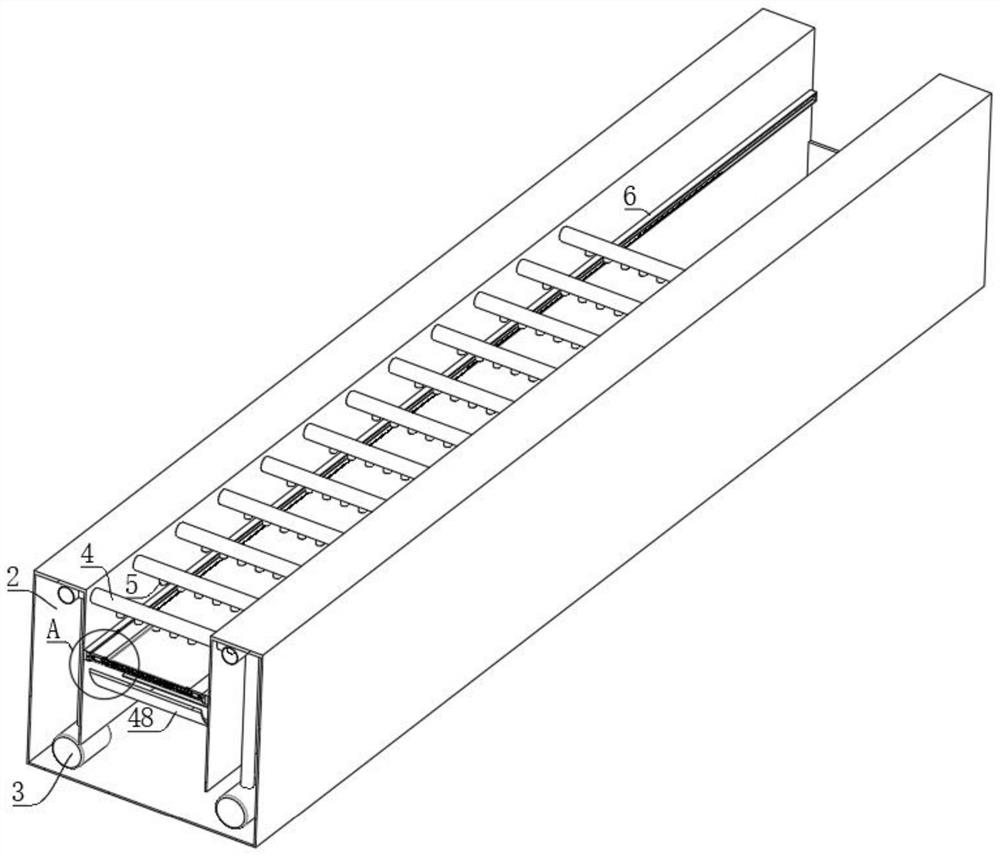

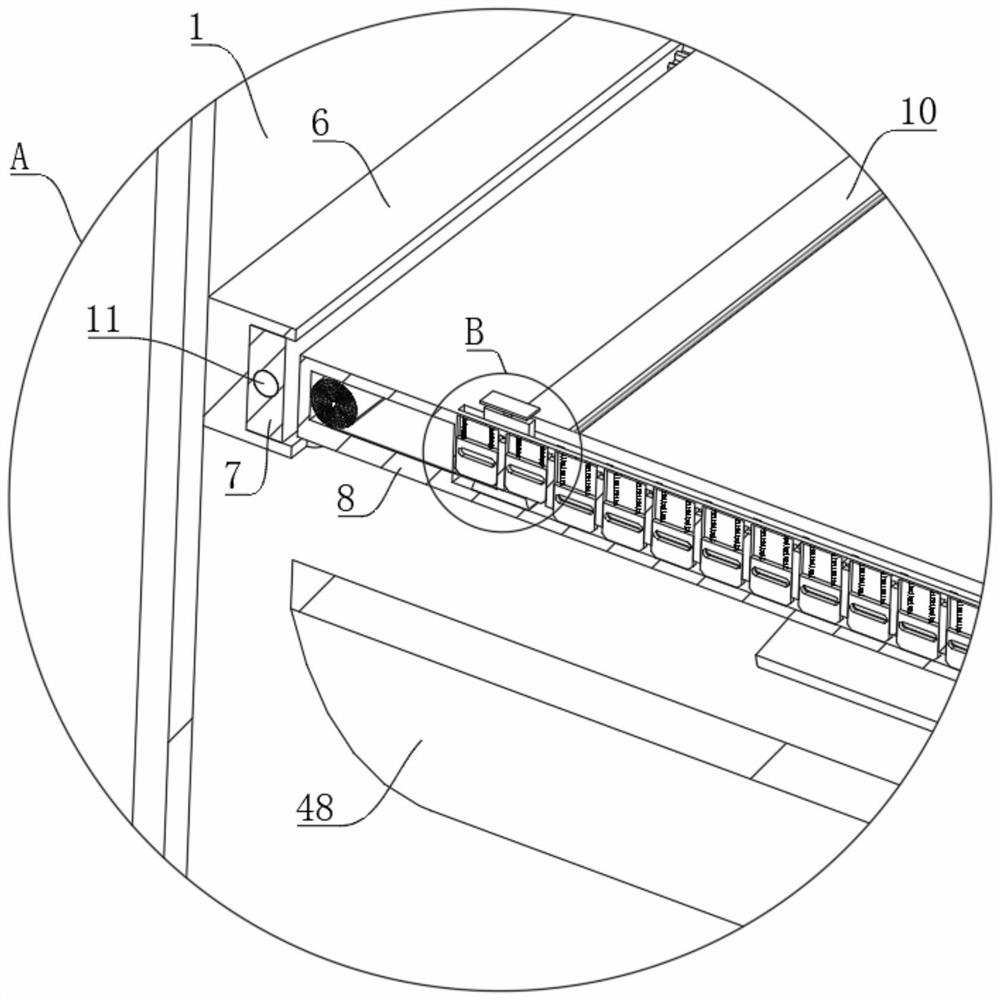

[0041] Such as Figure 1 to Figure 18 As shown, in order to achieve the above purpose, the technical solution adopted by the present invention is: a semi-etching device for an integrated circuit lead frame, including a housing 1, the two sides of the housing 1 are fixedly connected with a water storage tank 2, and the inside of the water storage tank 2 is fixed There is a water pump 3, and the outlet end of the water pump 3 is fixedly connected with a spray pipe 4 through a conduit, and the spray pipe 4 is fixed between the inner walls of the housing 1. The guide rails 6 are symmetrically fixed, and the inside of the guide rails 6 is slidably connected with a sliding bar 7. One side of one of the sliding ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com