System and method for removing SO3 by cyclically compounding fly ash and magnesium-based desulfurizer

A technology of fly ash and desulfurizer, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problem of no alkaline component reuse, reduce the risk of unexpected shutdown, and remove ABS adhesion and corrosion Problems, the effect of reducing running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

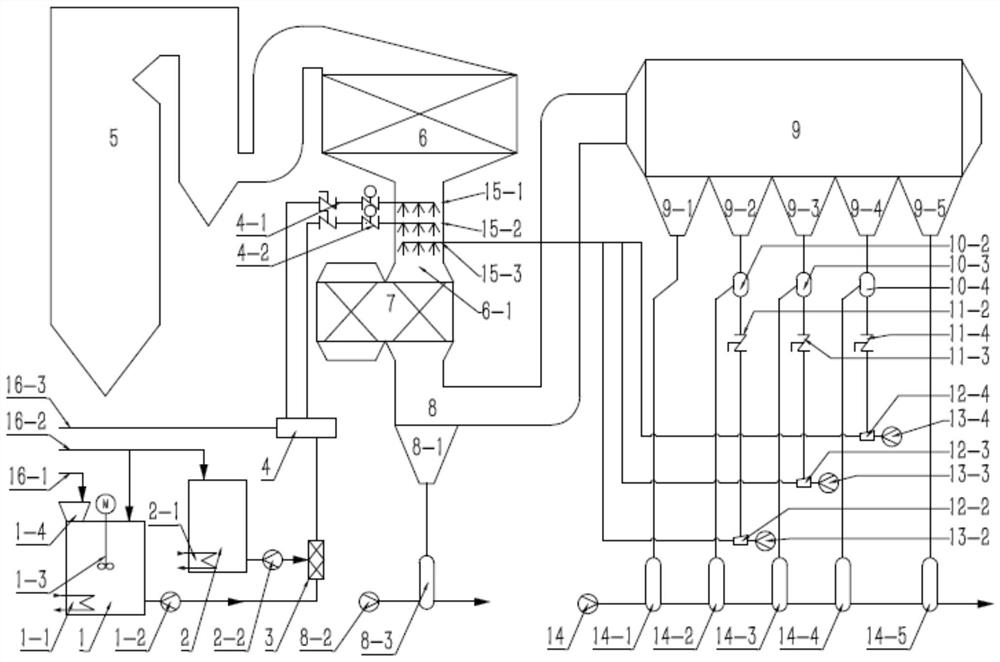

[0071] Take a 600MW unit as an example, the total smoke gas volume of 2 parallel SCR reactor 6 is 2 × 11.35 million nm. 3 / hr, dust concentration in flue gas 35g / nm 3 SO 3 200mg / m 3 408kg / hr SO 3 , Reaching 90% removal efficiency. Single-side SCR reactor tail flue 6-1 size is 4200x9206, configuring a total of 18 nozzle long spray guns 15-1, the injection coverage is 120%, the configuration single fluid multi-nozzle long spray gun 15-2 a total of 17 bits, injection The coverage is 110%, and the bilateral flue is shared by 36 bons and 34, and Mg / SO is set. 3 Molar ratio reached 1.6, co-spray magnesium base SO 3 Removal agent 5.9T / hr; set a gray sulfide ratio 220, circulating use of fly ash again 10.4T / HR, dust collector secondary gray struggle 9-2, dust collector three-stage land 9-3 and dust collector level 4 Fly ash for circulating and ejecting in the Dray 5-4 accounted for 51.9%, 28.8%, and 19.2% of the gray amount of the gray bucket, respectively.

[0072] The prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com