Columnar organic glass raw material extrusion device capable of eliminating bubbles

A plexiglass and raw material extrusion technology, which is applied in the field of plexiglass production, can solve problems such as product quality degradation that cannot eliminate air bubbles, and recycling of internal components in cleaning devices, so as to improve the effect and efficiency, improve work efficiency, and avoid waste of resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

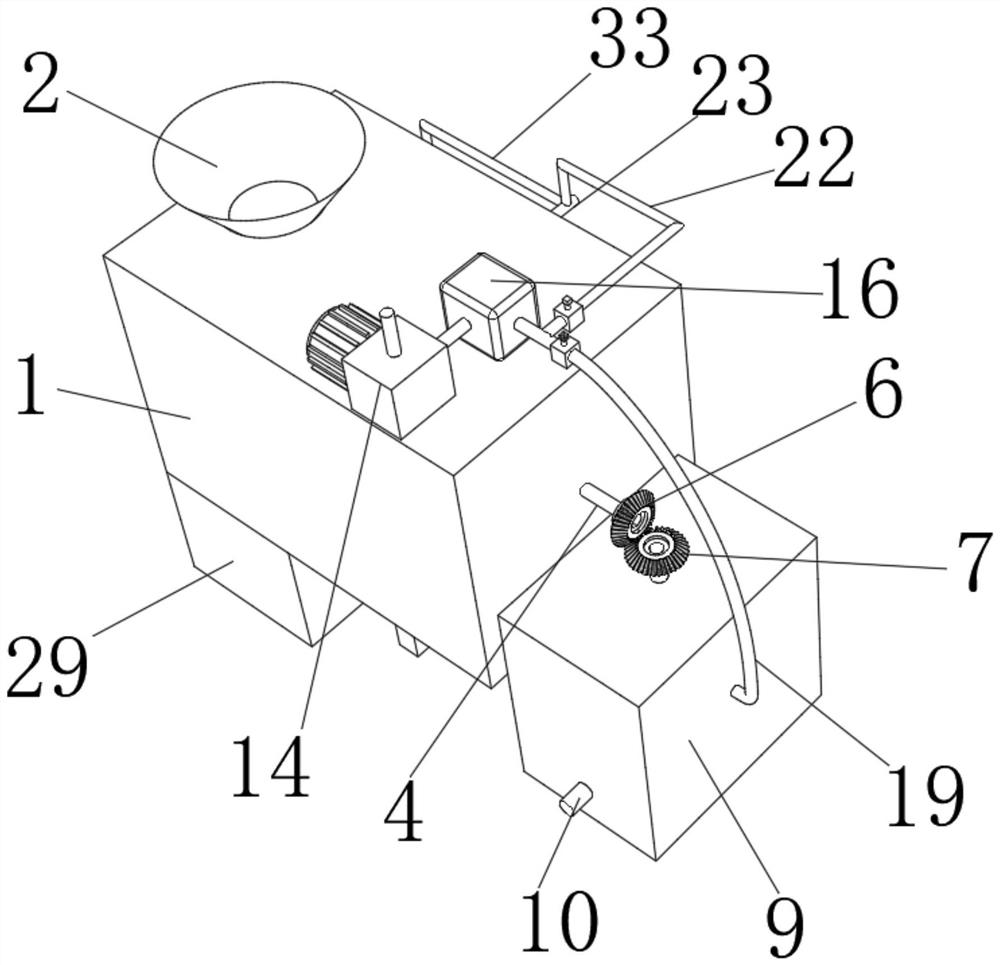

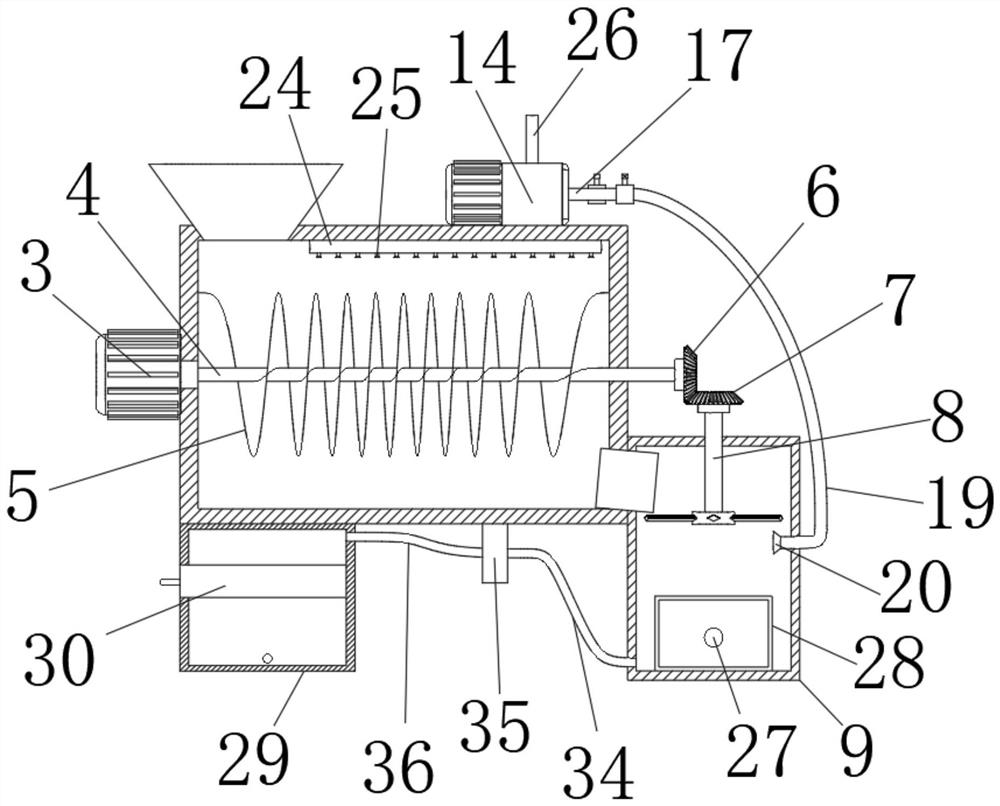

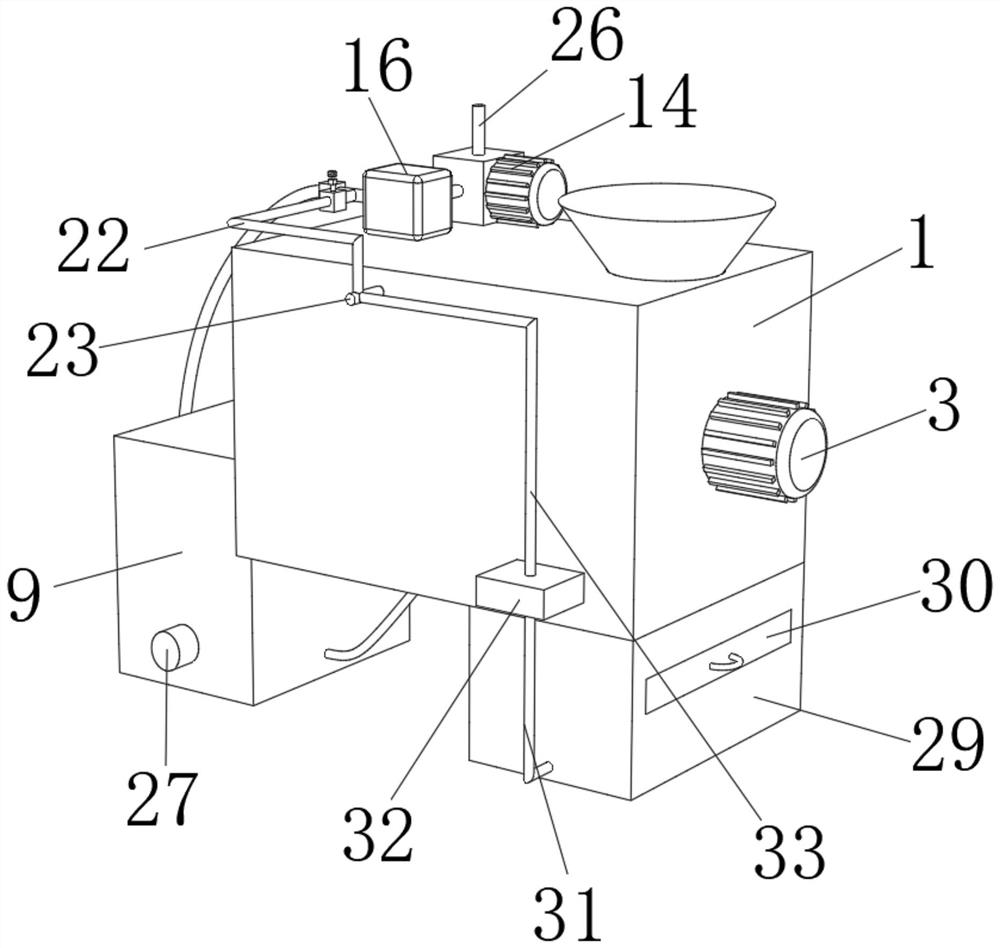

[0029] Such as Figure 1-6As shown, the embodiment of the present invention provides a columnar plexiglass raw material extrusion device that can eliminate air bubbles, including a delivery box 1, a motor 3 is fixedly connected to the left middle part of the delivery box 1, and the driving end of the motor 3 is fixedly connected to the connecting shaft 4, the connecting shaft 4 is fixedly connected with the spiral blade 5 on the outer diameter of the delivery box 1, the right end of the connecting shaft 4 is fixedly connected with the first bevel gear 6, and the lower side of the first bevel gear 6 is meshed with the second The bevel gear 7 and the inner through hole of the second bevel gear 7 are fixedly connected with a rotating shaft 8, and the bottom end of the rotating shaft 8 runs through the top of the extrusion box 9 and is fixedly connected with a turntable 11, and the outer side of the turntable 11 is fixedly connected with a stirring blade 12, The top right front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com