Automatic control method and system for continuous annealing furnace, computer readable storage medium and computer program product

An automatic control system and continuous annealing furnace technology, applied in the direction of heat treatment process control, furnace, heat treatment furnace, etc., can solve problems such as difficult to establish accurate mathematical models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

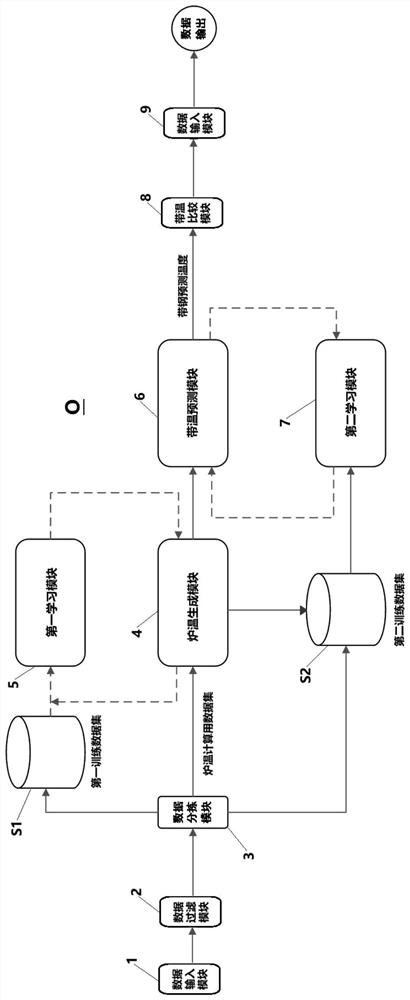

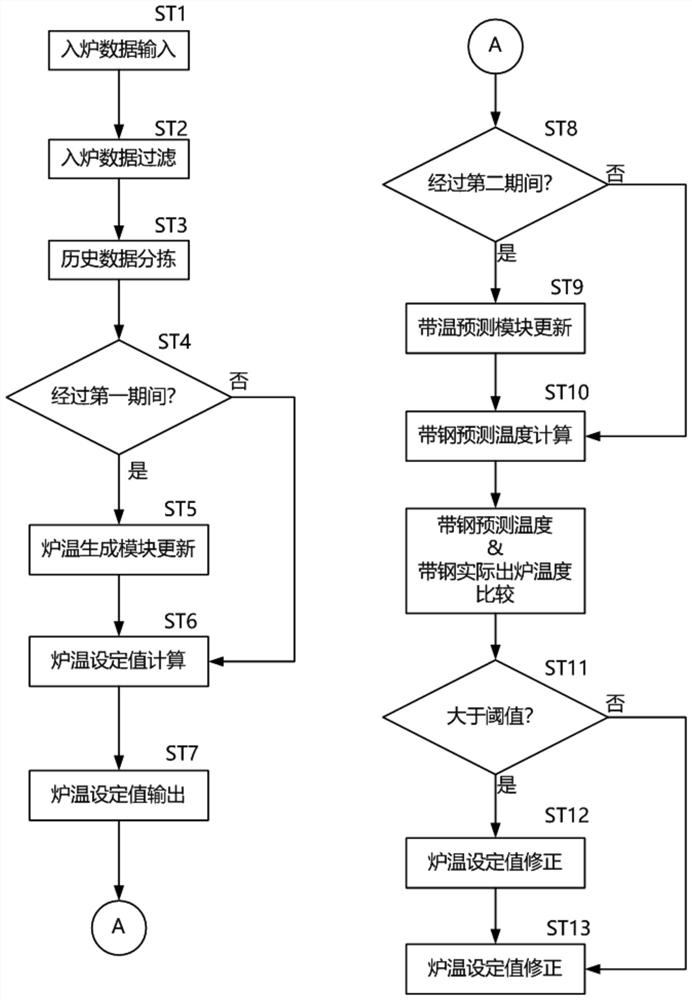

[0087] First, use Figure 1 to 2 Further, the detailed configuration of a continuous annealing furnace automatic control system according to an embodiment of the present invention will be described.

[0088] figure 1 A block diagram showing the automatic control system O of the continuous annealing furnace of the present invention is shown. Such as figure 1 As shown, the continuous annealing furnace automatic control system O includes a data input module 1, a data filtering module 2, a data sorting module 3, a furnace temperature generating module 4, a first learning module 5, a temperature prediction module 6, a second learning module 7 , A temperature comparison module 8, the furnace temperature correction module 9.

[0089] The data input module 1 is a module that receives the related data ie inputting furnace data when the strip-by-steel rolled steel entered the continuous annealing furnace is received, and the inclination data comprises at least a strip of steel, a steel thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com