Wind power tower cylinder transition section cylinder section with replaceable pre-stressed anchor bolts

A wind power tower and prestressing technology, applied in wind power generation, installation/supporting configuration of wind turbines, climate sustainability, etc., can solve problems such as potential safety hazards, low power generation efficiency, failure of prestressed anchor bolts, etc., to ensure Safety, simplification and difficulty of procedures, effect of guaranteed life cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

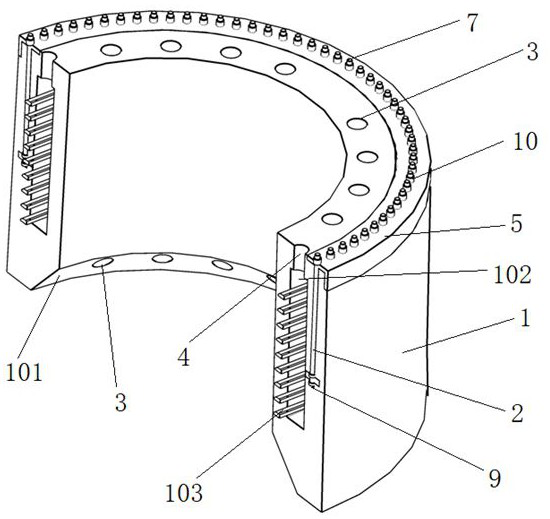

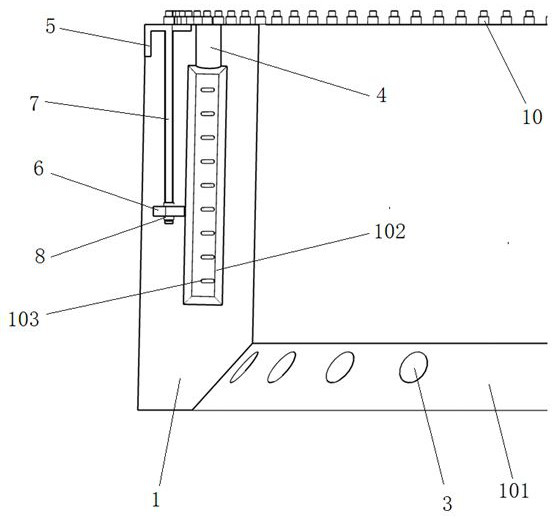

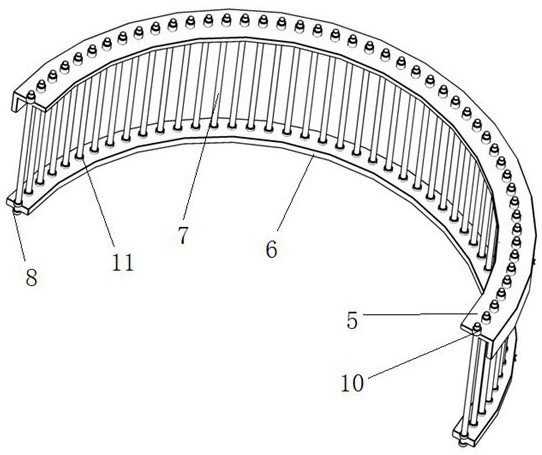

[0050] The tube section body of the tower in the transition section is composed of two semi-circular tube pieces 1 spliced together. The two tube pieces 1 are prefabricated by concrete. The outer diameter is 4.6m, the inner diameter of the bottom surface is 4m, and the height is 2.5m. The thickness of the top surface of the tubular sheet 1 is 750mm, the thickness of the bottom surface is 300mm, and the height of the transition surface 101 is 0.5m.

[0051] 45 prestressed anchor bolt holes 2 are reserved in each tube piece 1, and the prestressed anchor bolt holes 2 are evenly arranged along the circumferential direction of the tube piece 1 and are close to the outer wall of the tube piece 1. The diameter of the prestressed anchor bolt holes 2 is 53mm and a height of 1.5m.

[0052] 8 prestressed rib holes 3 are reserved in each tube piece 1, and the 16 prestressed rib holes 3 are divided into four groups along the ring direction of the tube section body, and the four groups o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com