Cylinder sleeve surface smoothness inspection device

A surface finish and inspection device technology, applied to measuring devices, material analysis through optical means, instruments, etc., to reduce potential quality and safety hazards, avoid visual damage, and improve inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

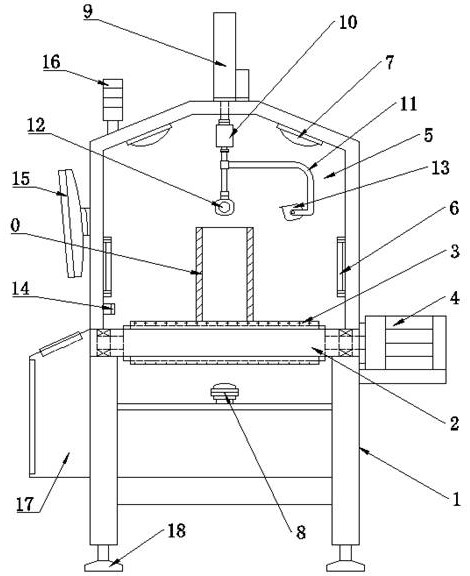

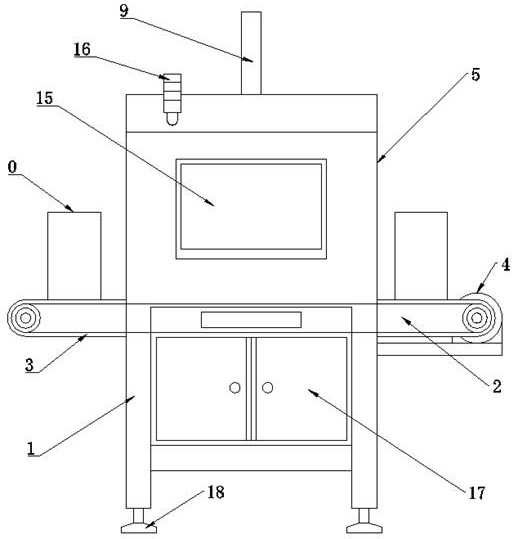

[0018] like Figure 1-2 As shown, a cylinder liner surface finish inspection device includes a frame 1, and a belt conveyor 2 for conveying cylinder liners 0 is erected above the frame, and the conveyor belt 3 of the belt conveyor adopts a transparent conveyor belt. One end of the driving roller of the conveyor is connected with a conveying motor 4. Multiple cylinder liners can be placed on the conveying belt at one time, and each cylinder liner is placed upright on the conveying center line of the conveying belt. A tunnel is arranged above the belt conveyor. In the camera room 5, side lights 6 are arranged on both sides of the inner wall of the camera room, a ceiling light 7 is arranged on the top of the camera room, a bottom light 8 for illuminating the inside of the cylinder liner is arranged under the conveying belt, and the top of the camera room is set in the middle There is a vertically downward electric telescopic rod 9, the lower end of the electric telescopic rod is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com