Practical training teaching system for assembly line

A technology for assembly production lines and teaching systems, applied in the field of teaching systems, which can solve problems such as lack of emergencies and application scenarios, difficulty in understanding and mastering knowledge points, and lack of hands-on and problem-solving capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the accompanying drawings. Moreover, according to the description of this document,

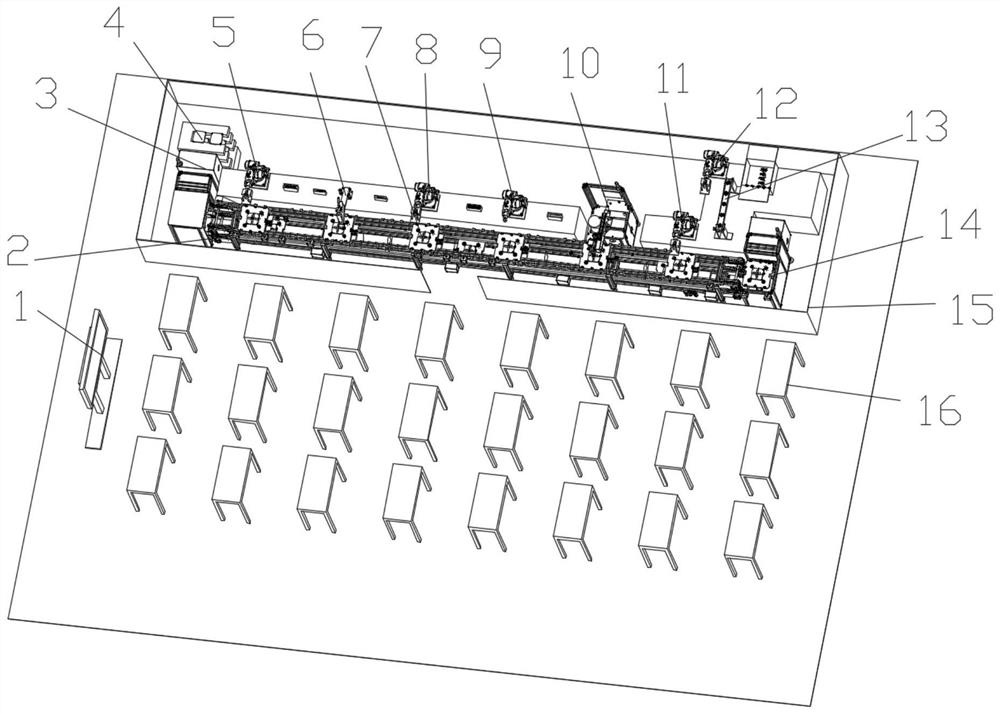

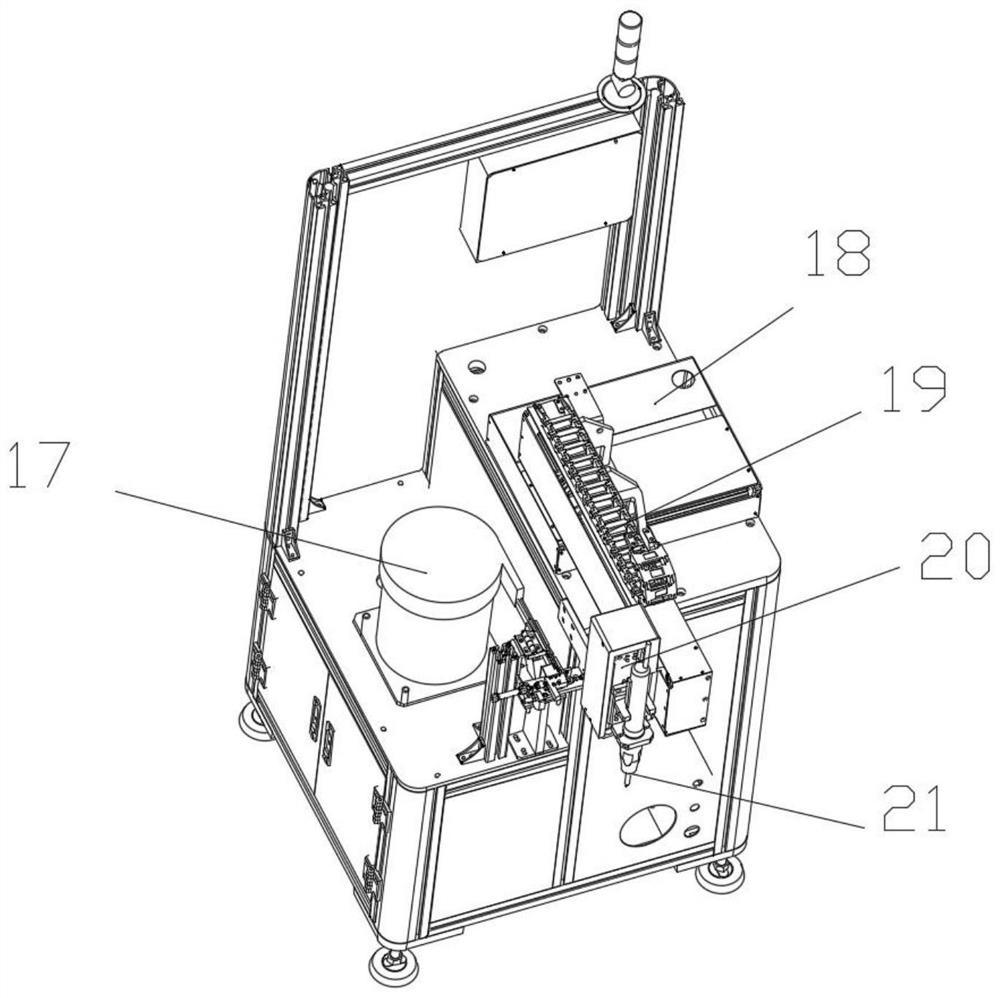

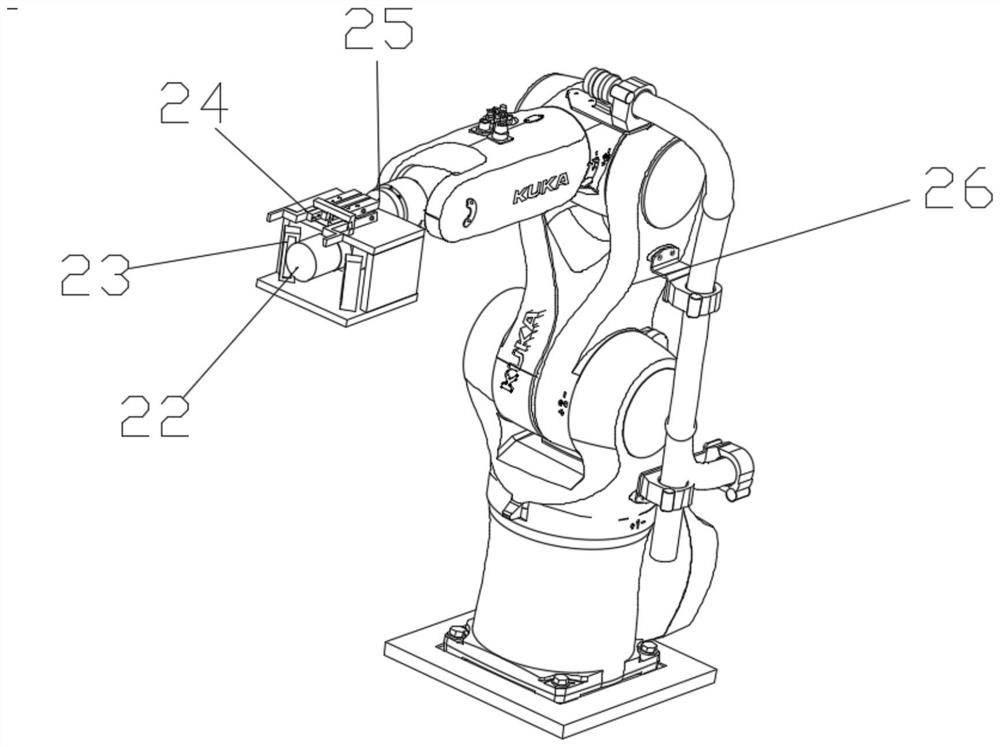

[0038] The invention is implemented, for example, figure 1 A assembly line training teaching system, including assembly line, the assembly line with a control system, the control system including a control module and a human machine interaction device, the assembly line sequentially provided a number of assemblies and fixed workers Bit, the assembly line includes a roller 2, a tray shifting device 7, a module storage device 4, a first gripper, a handling device, and an output device, the module storage device 4 memory with a positioning module for positioning the assembled workpiece 28, the first grab device is used to place the gripping positioning module 28 from the module storage device 4 into the tray shifting device 7, and the tray shifting device 7 is set to the roller 2. The roller 2 is moved, and the roller 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com