Integrated high-power signal source

A signal source, high-power technology, applied in transmission monitoring, comprehensive factory control, electrical components, etc., can solve the problems of ALC loop design circuit complexity, high cost, power device final stage power tube damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

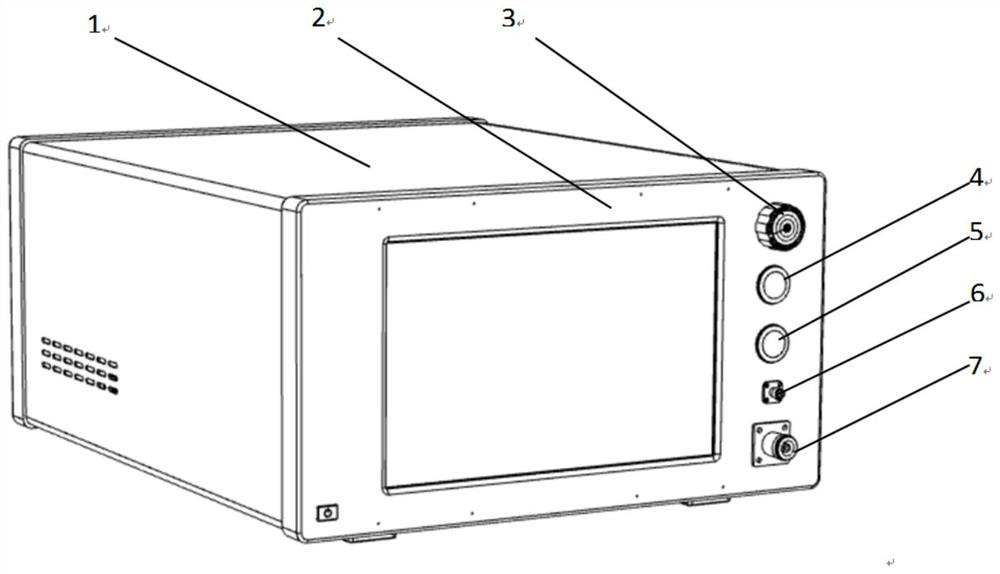

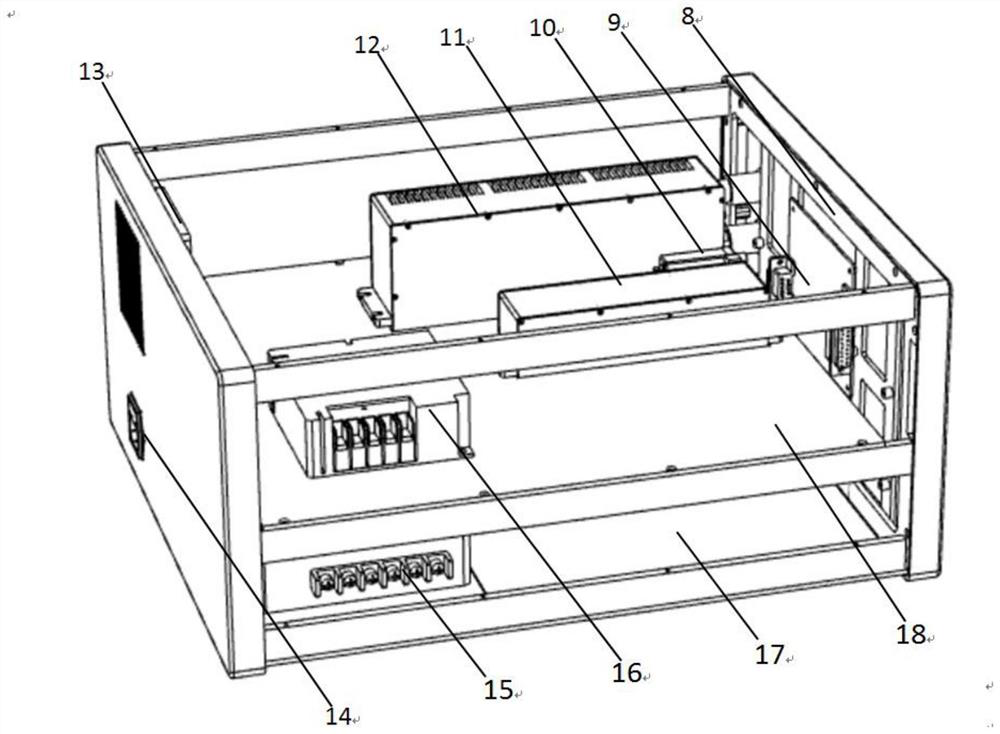

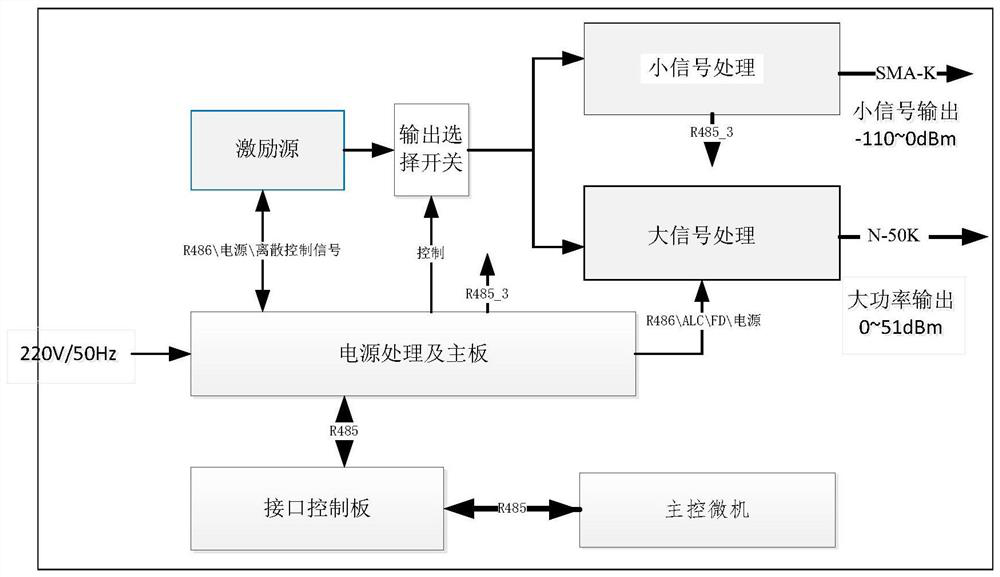

[0019] see Figure 1 to Figure 3 . In the preferred embodiment described below, an integrated high-power signal source instrument device includes: a power knob button 3 arranged on the front panel 2 of the chassis 1, a signal selection button 4, a transceiver button 5, a small signal output The interface SAM 6, the N-type large signal output interface 7, and the signal source power interface 14 on the side panel are fixed on the inner side wall of the chassis 1, and are arranged on the chassis mounting fixture 18, the 5V power module 16 and the 28V power supply below it Module 15, connected to the main control microcomputer 8 of the interface control module 9, connected in parallel with the power supply processing and the main board 17 and the excitation source module 11 and the output selection switch on the main board, connected to the small signal processing module 10 of the output selection switch and the large signal processing module 10 The module 12 is characterized in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com