Production method of refrigeration infrared detector

An infrared detector and device chip technology, which is applied in the field of semiconductors and can solve the problems that the physical connection and electrical connection between a readout circuit chip and a device chip cannot meet process requirements, device failure, indium column dislocation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

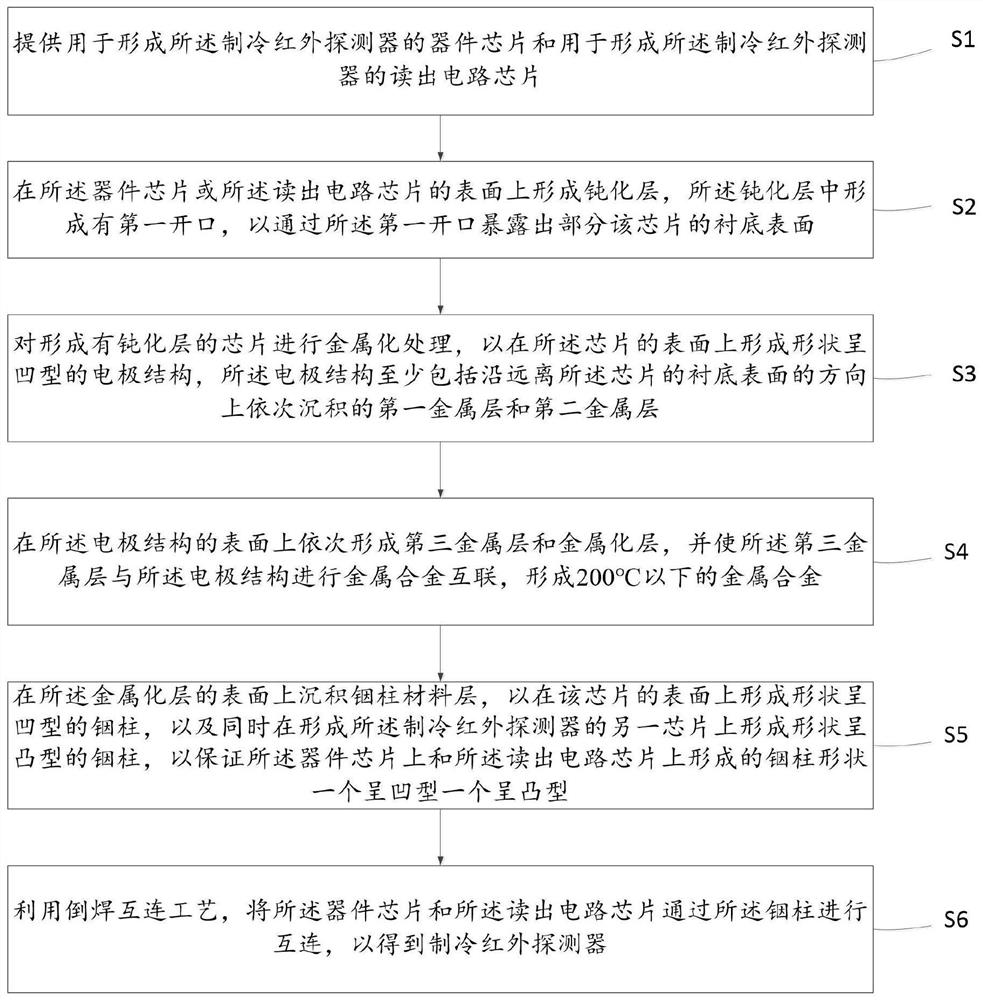

[0040] refer to figure 1 , figure 1 It is a schematic flow chart of a method for preparing a cooled infrared detector in an embodiment of the present invention provided in an embodiment of the present invention, and the method includes the following steps:

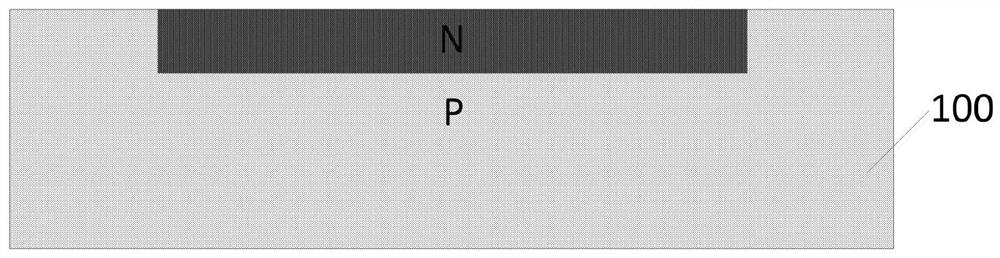

[0041] Step S1, providing a device chip for forming the cooled infrared detector and a readout circuit chip for forming the cooled infrared detector;

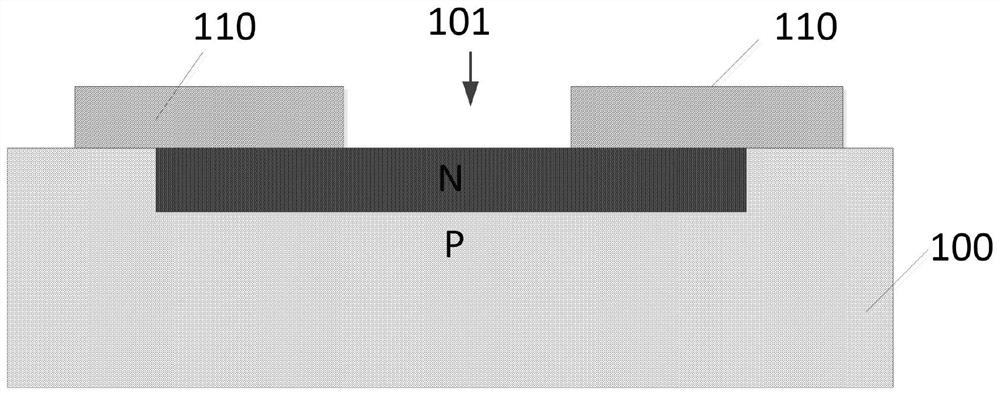

[0042] Step S2, forming a passivation layer on the surface of the device chip or the readout circuit chip, a first opening is formed in the passivation layer, so as to expose part of the substrate of the chip through the first opening surface;

[0043] S3, performing metallization treatment on the chip formed with the passivation layer, so as to form a concave electrode structure on the surface of the chip, the electrode structure at least includes sequentially along the direction away from the substrate surface of the chip Deposited first metal layer and second metal la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com