Ultrahigh voltage element

An ultra-high voltage and component technology, which is applied in the manufacture of electrical components, semiconductor devices, semiconductor/solid-state devices, etc., can solve problems such as uneven electric field distribution, improve uneven electric field distribution, reduce corner current crowding effect, and improve SOA Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following examples are listed and described in detail with the accompanying drawings, but the provided examples are not intended to limit the scope of the present invention. In addition, the drawings are for illustrative purposes only and are not drawn to original scale. In order to facilitate understanding, the same components in the following description will be described with the same symbols.

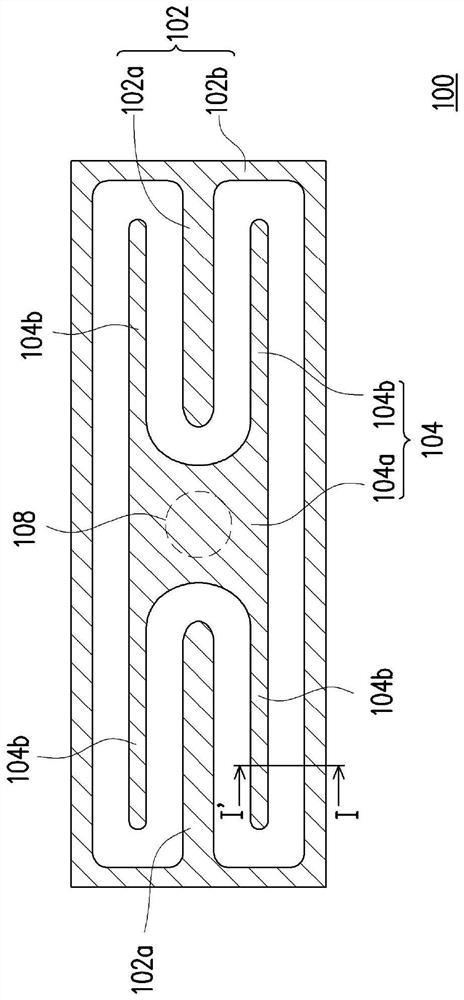

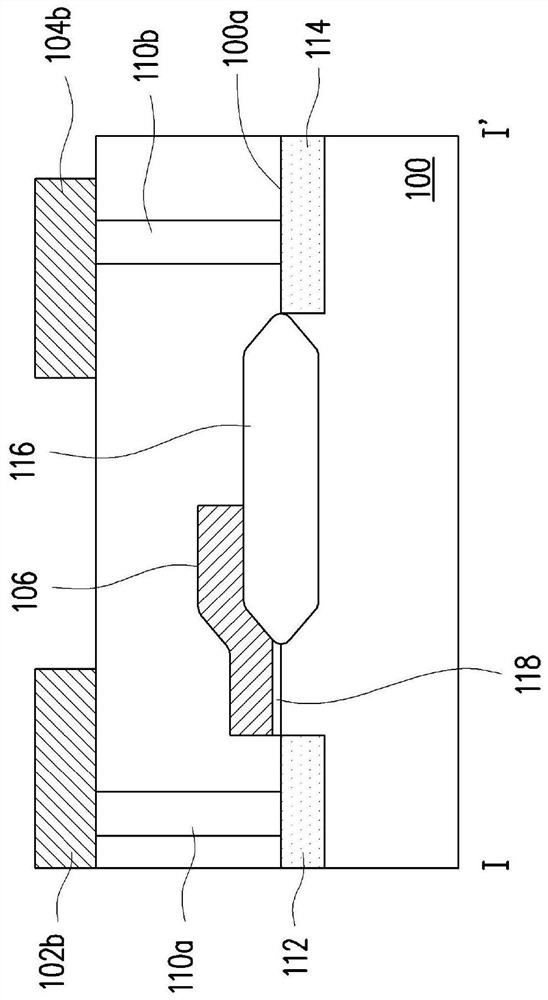

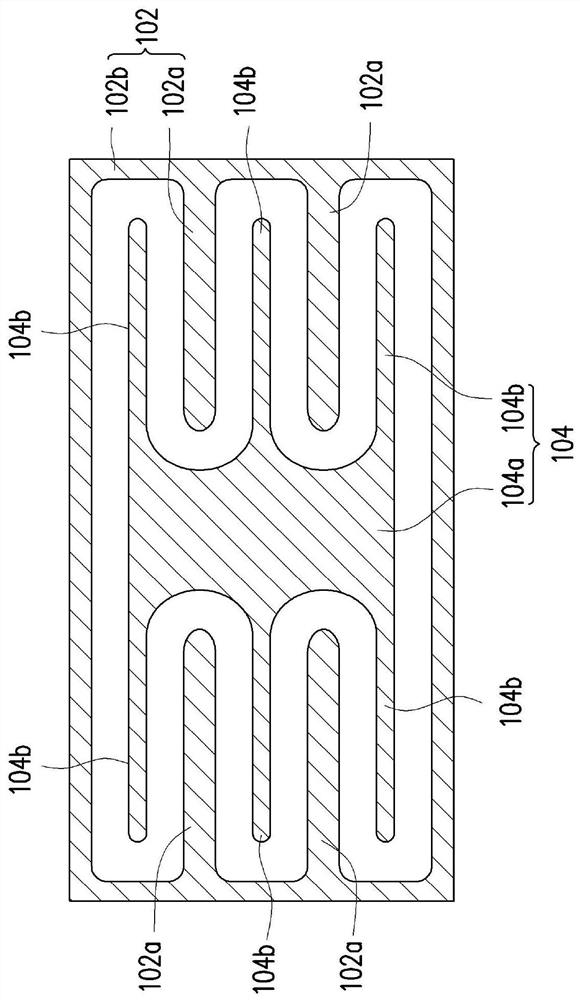

[0041] Figure 1A It is a schematic top view of an ultra-high voltage component according to an embodiment of the present invention. Figure 1B Yes Figure 1A The cross-sectional schematic diagram of the I-I' line segment.

[0042] Please refer to Figure 1A and Figure 1B , the ultra high voltage device includes a substrate 100 , an interdigitated source 102 , an interdigitated drain 104 and a gate 106 . The interdigitated source 102 is disposed on the surface 100a of the substrate 100, the interdigitated source 102 includes a plurality of first interdigitated portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com