Medium laser accelerator, vertical cavity surface laser and preparation method of vertical cavity surface laser

A vertical cavity surface, laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of limitation, high noise level, low electric field intensity in the acceleration area, etc., to achieve improved energy acceleration, simple structure, and improved acceleration. The effect of gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A dielectric laser accelerator, a vertical cavity surface laser (VECSEL) and a manufacturing method thereof according to the present invention will be further described in detail below with reference to specific embodiments and accompanying drawings.

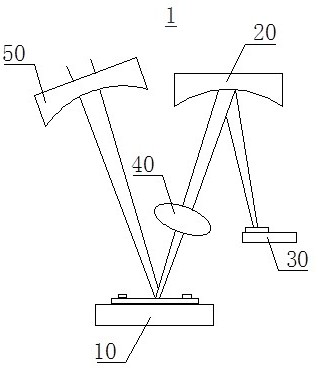

[0031] Please refer to figure 1 , for the convenience of explanation, define an XYZ space Cartesian coordinate system, the dielectric laser accelerator 1 of the present invention is used to accelerate electrons emitted from a radiation source, and it mainly includes a vertical cavity surface laser (VECSEL) 10, a mirror 20, and a saturable absorber Mirror 30. figure 1 For the convenience of observation, the radiation source and the light source for providing infrared laser light to the VECSEL 10 are omitted. It can be understood that the existing radiation source and light source can be used. The laser light generated by the radiation source is accelerated by the VECSEL 10, and the reflector 20 is arranged on the optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com