Detachable ion beam accelerating tube

A technology of ion beams and accelerating tubes, applied in accelerators, electrical components, etc., can solve problems such as waste and achieve high acceleration gradients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto.

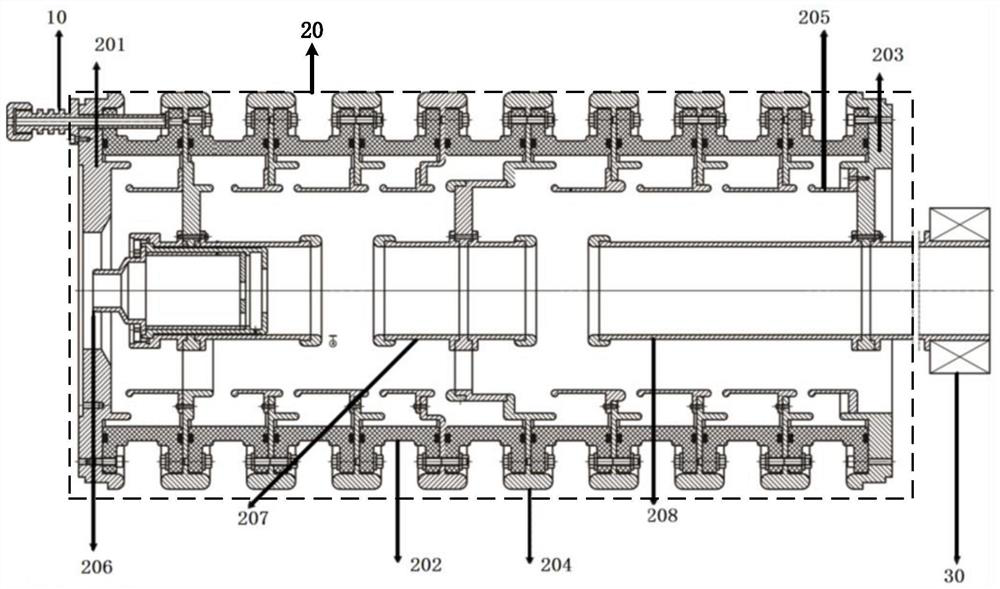

[0039] see figure 1 As shown, the detachable ion beam acceleration tube provided by the present invention includes: a high-voltage insulator 10 , an acceleration chamber 20 and a suppression magnet 30 .

[0040] Among them, the high-voltage insulator 10 is used to introduce initial convergence voltage into the ion beam accelerating tube. In practical application, the initial convergence voltage is about -30kV, and the initial convergence voltage is about 250kV DC high voltage as the reference ground, thus, the working voltage of the entire ion beam accelerating tube is about 280kV.

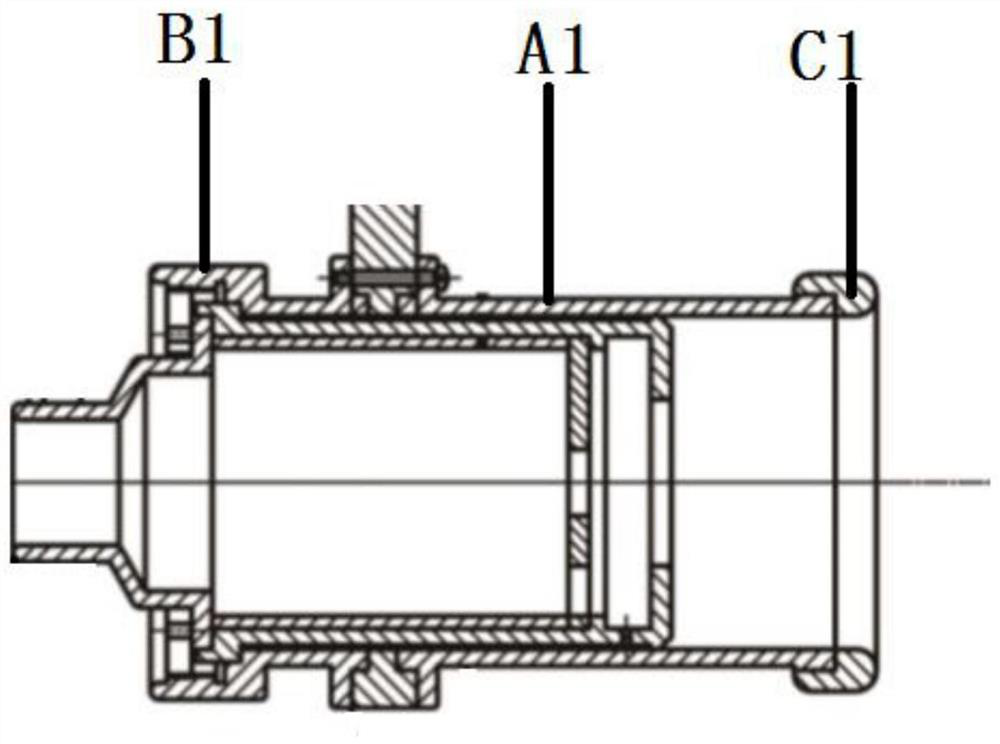

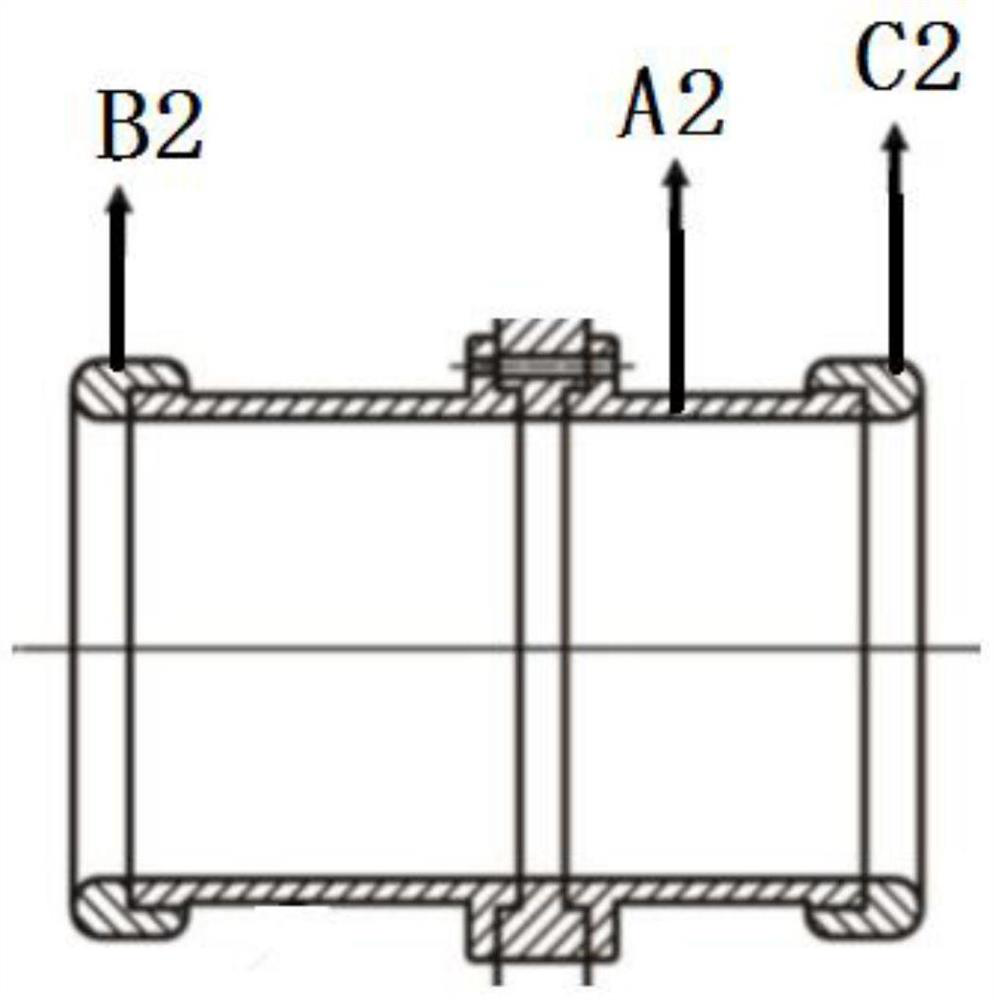

[0041] The acceleration cavity 20 is used to accelerate the ion beam drawn out by the ion source. The acceleration chamber 20 includes an input flange 201, a multi-stage insulating ring 202, and an output flange 203;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com