Automatic production system of rice machine-transplanted seedling raising factory

A production system and seedling technology, which is applied in the direction of transplanting machinery, seeder parts, guiding agricultural machinery, etc., can solve the problems of high rice planting cost, high labor intensity of workers, and unfulfilled mechanized operation requirements, so as to improve the expansion of facilities Utilization, ingenious structure setting, and the effect of reducing personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

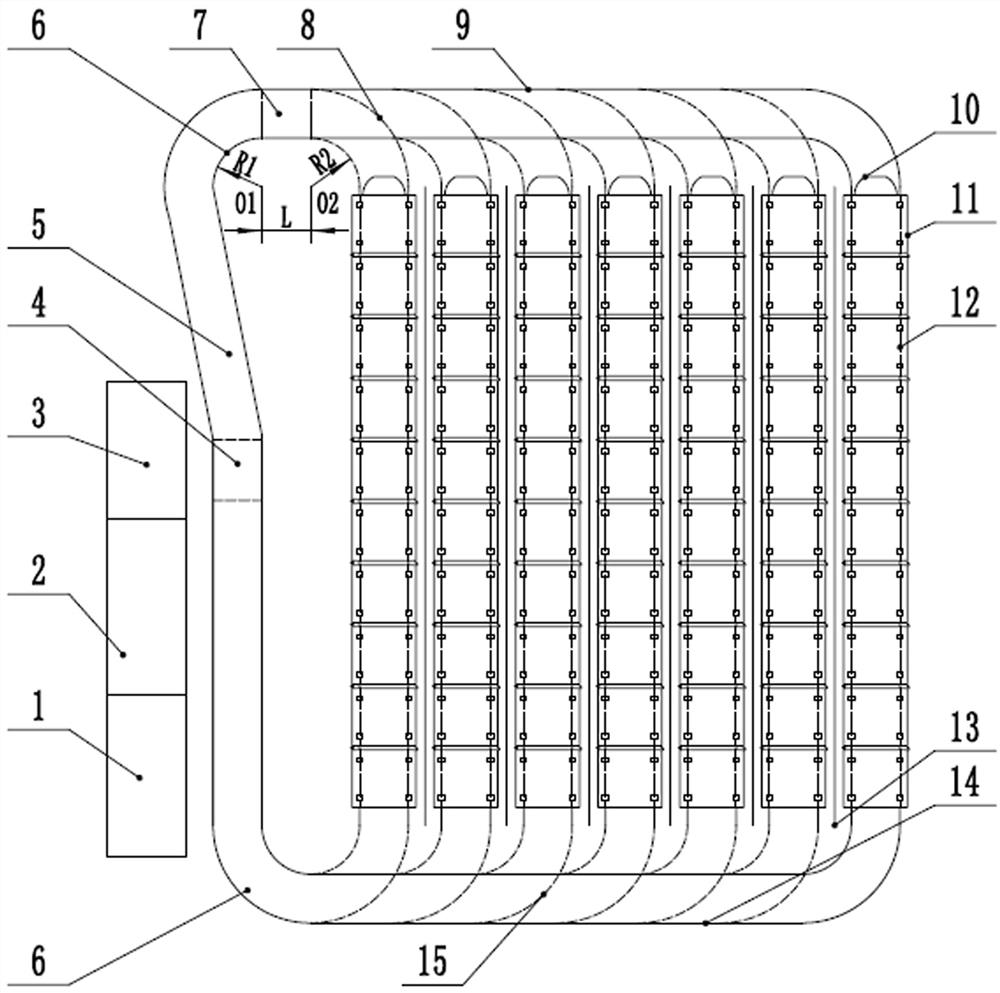

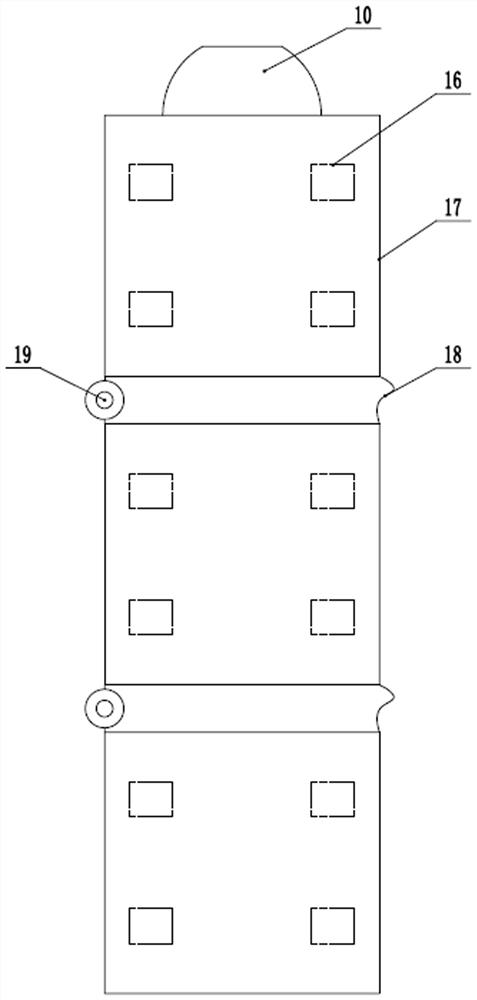

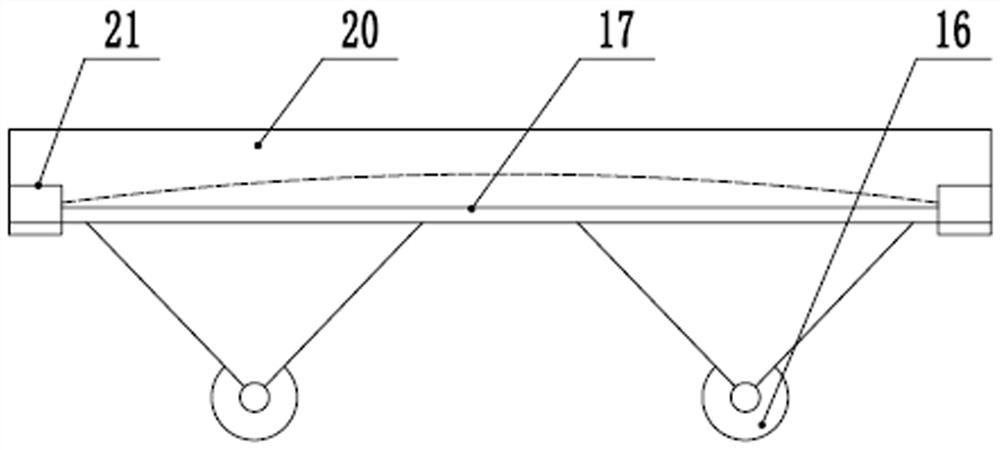

[0027] An automatic production system for a rice machine-transplanted seedling nursery factory, which includes a seeding area track 5, a common track 9 for seedling emergence, and a shared track 14 for sowing; multiple seedling raising tracks 12 are arranged between the shared track 9 for seedling emergence and the shared track 14 for sowing ;

[0028] The two ends of a plurality of seedling seedling raising tracks 12 are respectively connected with the shared track 9 and the shared track 14 for seedling removal by connecting the guide track 8 and the automatic guide track 15, except that the seedling seedling raising track 12 and the shared track for seedling removal are far away from the track 5 side of the sowing area. 9 and the guide rail that seeding common track 14 connects can directly adopt fixed guide rail, do not adopt automatic guide rail 8; On every seedling raising seedling track 12, the train type seedling raising platform 11 that vehicle can remote control drivin...

Embodiment 2

[0034] An automatic production system for a rice machine-transplanted seedling nursery factory, which includes a seeding area track 5, a common track 9 for seedling emergence, and a shared track 14 for sowing; multiple seedling raising tracks 12 are arranged between the shared track 9 for seedling emergence and the shared track 14 for sowing ;

[0035] The two ends of a plurality of seedling seedling raising tracks 12 are respectively connected with the shared track 9 and the shared track 14 for seedling removal by connecting the guide track 8 and the automatic guide track 15, except that the seedling seedling raising track 12 and the shared track for seedling removal are far away from the track 5 side of the sowing area. 9 and the guide rail that seeding common track 14 connects can directly adopt fixed guide rail, do not adopt automatic guide rail 8; On every seedling raising seedling track 12, the train type seedling raising platform 11 that vehicle can remote control drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com