Weak cross-linked high polymer for oil-based drilling fluid leakage stoppage and preparation method thereof

An oil-based drilling fluid and high polymer technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of difficult cross-linking reaction, loose plugging layer, and difficult pore particle size gradation, etc. Achieve the effects of improving anti-destructive performance, improving elastic deformation, and good safety and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing a weakly cross-linked polymer for oil-based drilling fluid plugging, which comprises:

[0037] High polymers containing active groups, oil-soluble cross-linking agents, oil-soluble initiators and solvents are mixed, heated for reaction, and shear granulated to obtain weakly cross-linked polymers for oil-based drilling fluid plugging;

[0038] The high polymer containing active groups is one or more of polybutadiene, polyisoprene, polybutadiene-styrene, polyacrylonitrile-butadiene-styrene and the like.

[0039]The preparation method of the weakly cross-linked high polymer for oil-based drilling fluid plugging provided by the invention mixes the high polymer containing active groups, an oil-soluble cross-linking agent, an oil-soluble initiator and a solvent.

[0040] First, the high polymer containing active groups is dissolved in a solvent or heated and melted, and stirred.

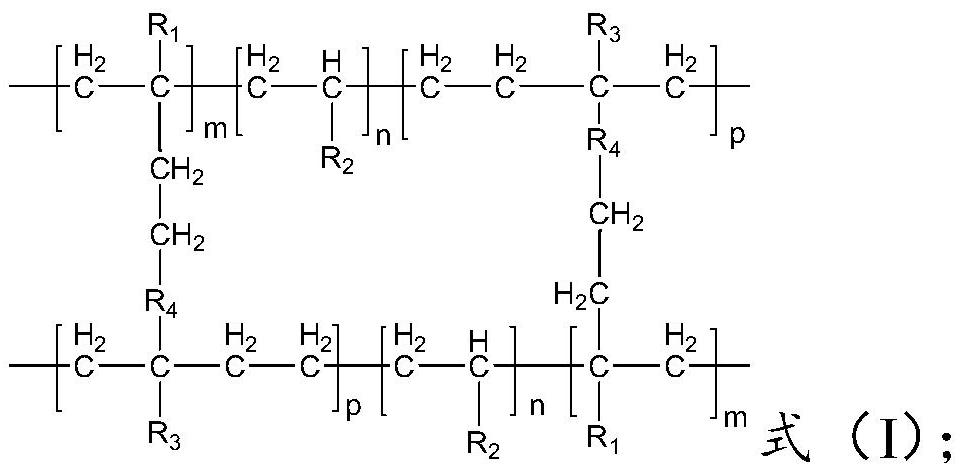

[0041] The polymer containing active groups descr...

Embodiment 1

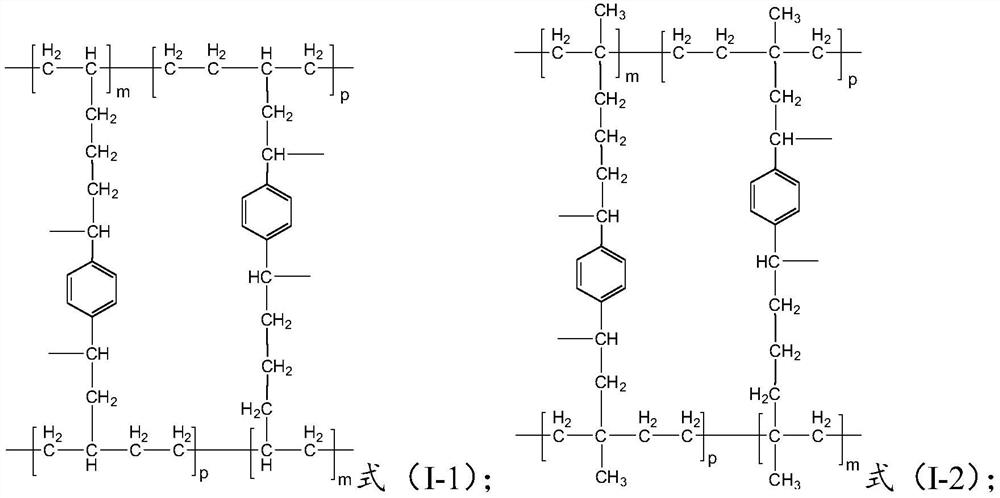

[0073] Dissolve 20g of polybutadiene in ethyl acetate, add 0.8g of crosslinking agent divinylbenzene and 0.8g of initiator azobisisobutyronitrile after fully dissolving, heat to 80°C after fully dissolving, and polymerize for 6 hours, Granulating to obtain a weakly cross-linked polymer for oil-based drilling fluid plugging, its structural formula is:

[0074]

[0075] Wherein, the molecular weight is 250,000-330,000, m, p is the degree of polymerization, and the range is m:p=(450-560):(4100-5100).

Embodiment 2

[0077] Dissolve 20g of polyisoprene in ethyl acetate, add 0.8g of crosslinking agent divinylbenzene and 0.8g of initiator BPO after fully dissolving, stir evenly, heat to 80°C, polymerize for 6 hours, and granulate to obtain Weakly cross-linked polymer for oil-based drilling fluid plugging, its structural formula is:

[0078]

[0079] Wherein, the molecular weight is 280,000-350,000, m, p is the degree of polymerization, and the range is m:p=(400-750):(3400-4500).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com