Automatic warehouse-in and warehouse-out mechanism of calandria type quick-freezing warehouse and logistics conveying system applying same

A technology of quick-freezing warehouse, in-out warehouse, applied in applications, home appliances, transportation and packaging, etc., can solve the problems of labor and time consumption, inconvenient placement and removal of materials, low efficiency, etc., to reduce labor costs and save labor costs. , Accurate effect of out-of-warehouse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

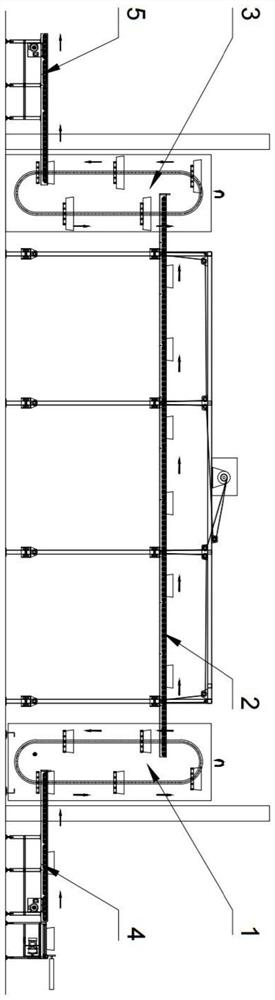

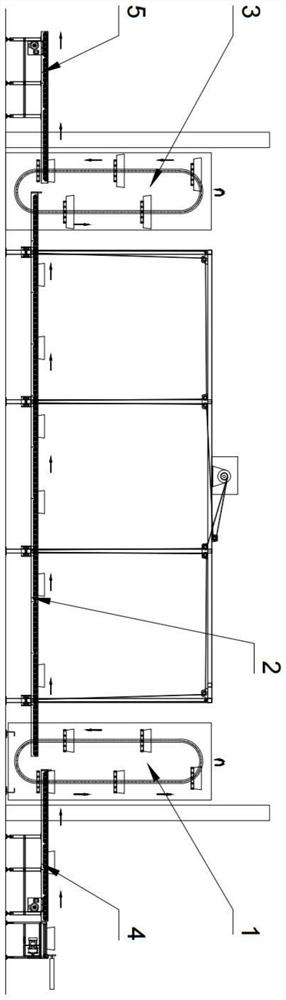

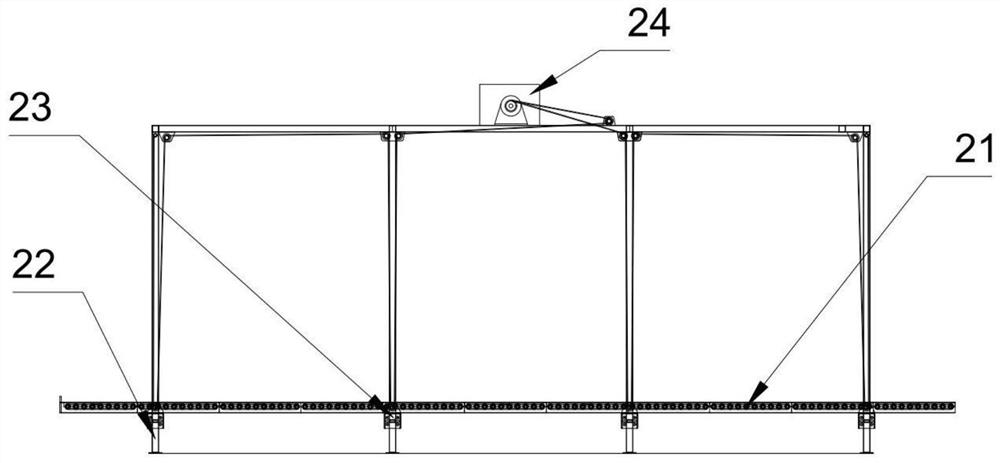

[0041] This embodiment provides an automatic warehouse entry and exit mechanism for a row-pipe type quick-freezing warehouse, see figure 1 , figure 2 and Figure 8 , located in the quick-freezing warehouse 10, including a feeding module 1, a transport module 2 and a discharging module 3, the feeding module 1 and the discharging module 3 are respectively located at the entrance and exit positions of the quick-freezing warehouse 10 at the front and rear ends of the quick-freezing warehouse 10, and are respectively used For the receiving and exporting of materials, the transportation module 2 is located between the feeding module 1 and the discharging module 3 and is used for the transfer of materials in the quick-freezer 10 .

[0042] Further, combine Figure 7 , the quick-freezing warehouse 10 is provided with a locker 6 inside, and the locker 6 is a multi-storage layer structure composed of several rows of pipes. The storage layer is used to place materials that need to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com