Polarization type LED light-emitting device and manufacturing method thereof

A technology for a light-emitting device and a manufacturing method, which is applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as affecting user experience, prone to failure, affecting heat dissipation, etc., and achieves increasing 3D polarized display mode, reducing power consumption, and reducing thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

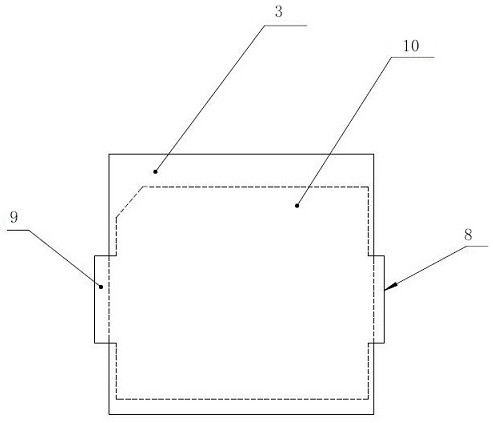

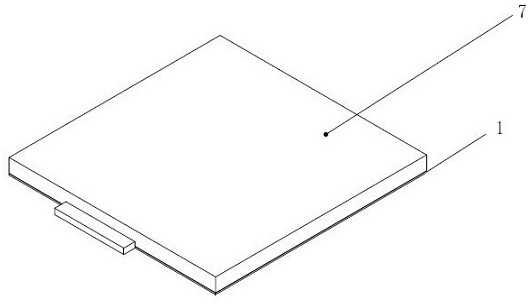

[0033] Embodiment one: see figure 1 , 2 To 6, technical scheme of the present invention is:

[0034] A polarized LED light-emitting device, comprising a single light-emitting chip and a polarized light-transmitting layer. The light-emitting chip is located at the bottom of the LED light-emitting device, and the polarized light-transmitting layer is located directly above it. A light-transmitting glue is arranged between the chip and the polarized light-transmitting layer, and a light-shielding component is arranged on the periphery of the light-emitting chip.

[0035] The polarized light-transmitting layer is a glass polarizer.

[0036] The glass polarizer adopts a multi-layer film structure, and oblong nanoparticles are embedded in one layer, and are sandwiched between two adjacent sheets.

[0037] The glass polarizer adopts two different crystal materials, which are glued together through a wedge-shaped structure, one is in the lower layer, and the other is in the upper l...

Embodiment 2

[0052] Embodiment two: with reference to attached image 3 , is generally the same as Embodiment 1, the difference is that the polarized light-transmitting layer adopts a multi-layer film structure, wherein two layers are glass slides, and oblong nanoparticles are embedded in the middle of the two layers, so that the glass slides It has a linear grid effect and can selectively transmit the light generated by the light-emitting chip.

[0053] Step 1: Use adhesive to fix the LED chip on the circuit board or bracket, and use wires to connect the positive and negative poles of the chip to the substrate;

[0054] Step 2﹑preheating the semi-finished product formed in step 1;

[0055] Step 3: Use a glue dispenser to dispense glue in step 3 with A glue, the thickness is enough to cover the LED power generation chip;

[0056] Step 4. Bake the semi-finished product in step 3 to cure the light-transmitting glue filled in each LED lamp bead bracket;

[0057] Step 5: Paste the prepared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com