Ternary metal palladium-based catalyst as well as preparation method and application thereof

A ternary metal and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as high cost and low efficiency, and achieve high-efficiency formic acid Dehydrogenation, simple preparation method, and the effect of enhancing the dehydrogenation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

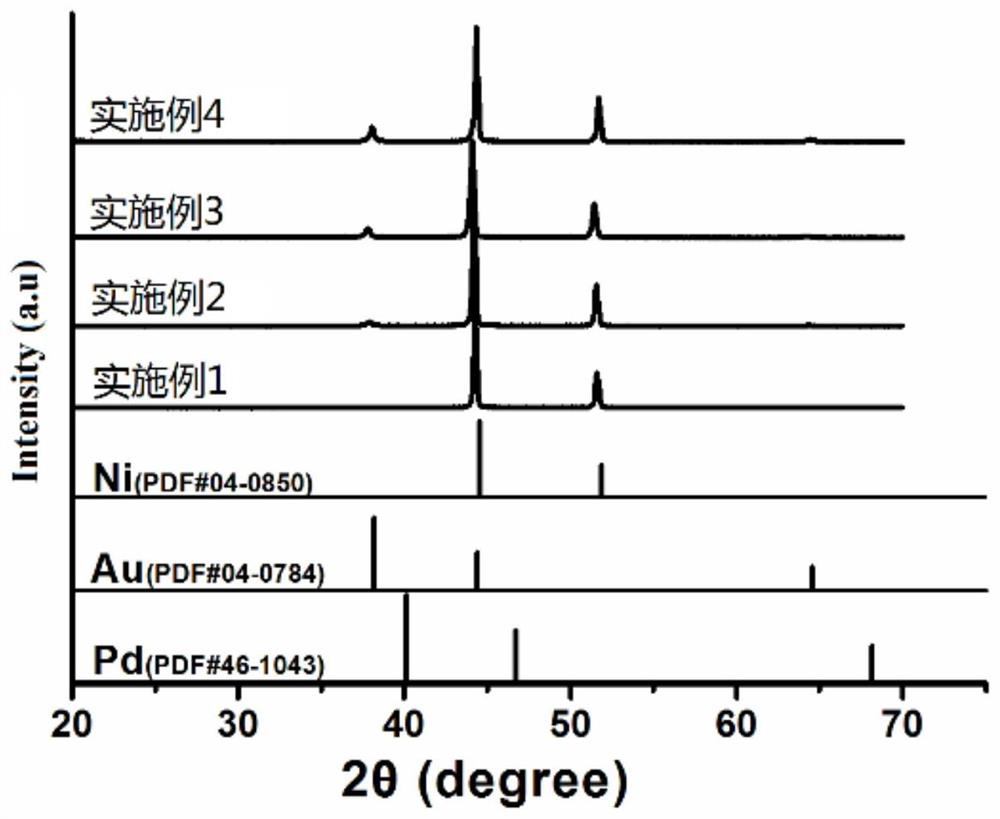

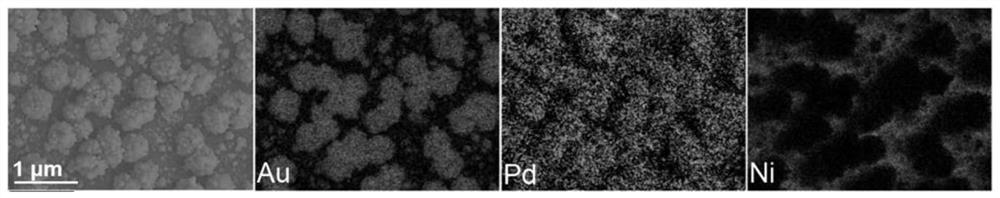

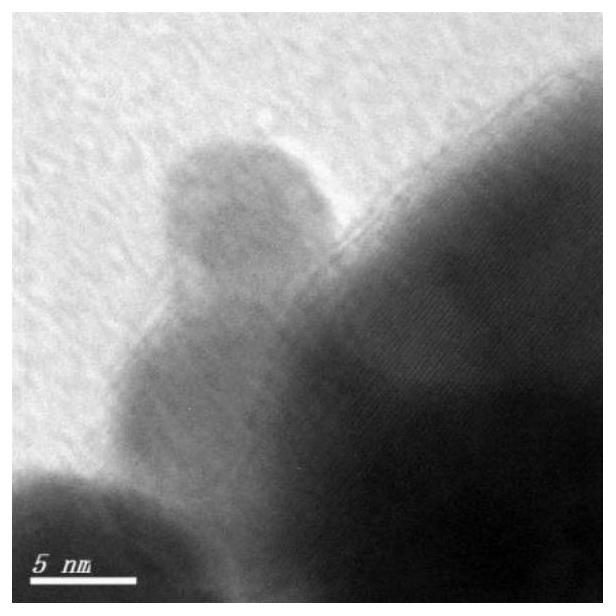

[0033] A kind of preparation method of ternary metal palladium-based catalyst of the present invention, silver-white foamed nickel is placed in gold salt solution (such as chloroauric acid solution), ultrasonically reacts, obtains the foamed nickel of tawny gold load, uses deionized water Wash the sample repeatedly with ethanol, dry the gold-loaded foam nickel naturally, immerse it in a palladium salt solution (such as a solution of sodium chloropalladate), use a reducing agent to reduce the palladium ions, leave it to age for a period of time, and use it to remove the palladium ions. The samples were rinsed repeatedly with ionized water and ethanol, and dried naturally to obtain a ternary metal palladium-based catalyst. Specifically include the following steps:

[0034] (1) At room temperature, weigh 20mm*10mm*2mm (0.0200-0.0290g) nickel foam and place it in deionized water, ethanol, acetone and hydrochloric acid (0.1-2M) in turn, shake and ultrasonic for 3-40 minutes each ,...

Embodiment 1

[0051] At room temperature, place a piece of 20mm*10mm*2mm silver-white foam nickel in deionized water, ethanol, acetone and hydrochloric acid (0.1-2M) for 10 minutes, and place it in 0 μL chloroauric acid solution after drying naturally. (5-50mM) while shaking and sonicating for 5-10 minutes, respectively, to obtain the yellow-brown gold-loaded nickel foam. Rinse the sample repeatedly with deionized water and ethanol, dry the gold-loaded nickel foam naturally, place it in a solution containing 5-100 μL sodium chloropalladate (5-50 mM), and use 10-1000 μL ascorbic acid ( 0.01-1M) to reduce palladium ions, let stand for aging for 10-100min, use deionized water and ethanol to wash the sample repeatedly, and dry naturally to obtain a binary palladium-based catalyst.

Embodiment 2

[0053] At room temperature, put a piece of 20mm*10mm*2mm silver-white nickel foam in deionized water, ethanol, acetone and dilute hydrochloric acid (0.1-2M) and wash it repeatedly for 10 minutes each. In the solution (5-50mM), shake and sonicate for 5-20 minutes, respectively, to obtain the yellow-brown nickel foam loaded with gold. Rinse the sample repeatedly with deionized water and ethanol, dry the gold-loaded nickel foam naturally, place it in a solution containing 5-100 μL sodium chloropalladate (5-50 mM), and use 10-1000 μL ascorbic acid after the droplets are fully diffused (0.01-1M) to reduce palladium ions, let it stand for aging for 10-100min, use deionized water and ethanol to wash the sample repeatedly, and dry naturally to obtain a ternary metal palladium-based catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com