Efficient and clean utilization technology for highly volatile young coal

A highly volatile and young technology, applied in the chemical industry, petroleum industry, climate sustainability, etc., can solve problems such as blade corrosion and gas turbine blade wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

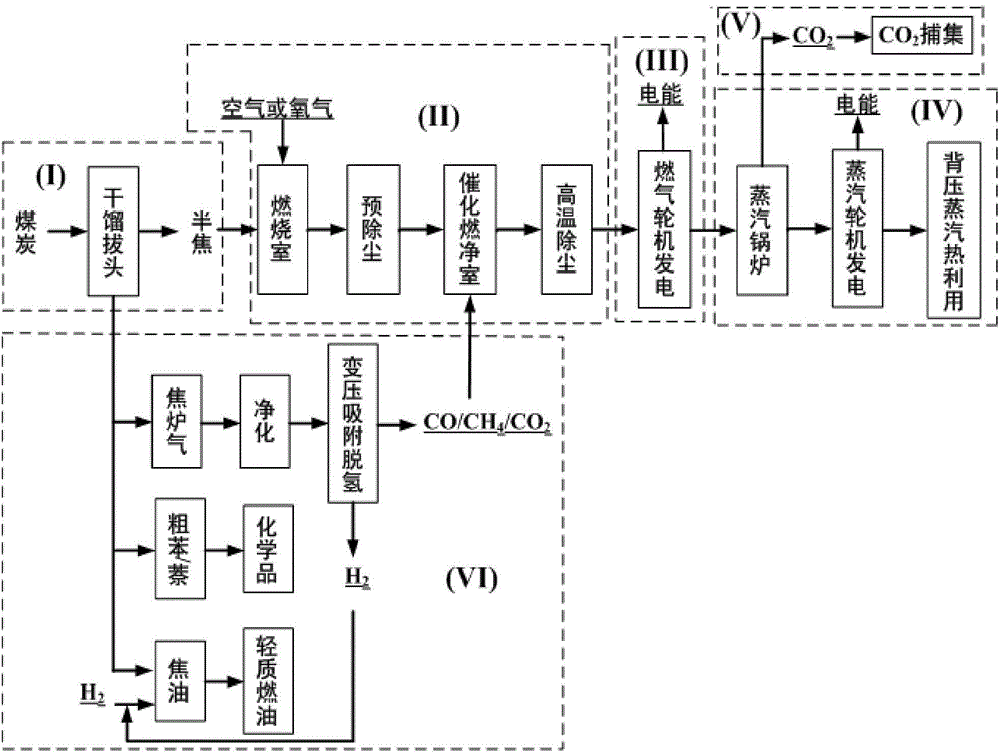

[0056] Using lignite as raw material, in technology module I young coal dry distillation topping technology, lignite is crushed and sieved to obtain 6-20mm fragments, which are put into a low-temperature carbonization furnace and then dried in a preheating section at 150°C. The final coal block enters the dry distillation section at about 560°C for dry distillation. After dry distillation, it passes through the cooling section to obtain solid semi-coke, raw gas, crude benzene, crude naphthalene, tar, etc. The total amount of residual alkali metal in the solid semi-coke after dry distillation is 0.020 mg / kg. Then the semi-coke is crushed in the technical module II oxygen-enriched direct combustion preparation high-temperature gas turbine working fluid system, enters the combustion chamber, and is directly burned in a pure oxygen atmosphere to obtain a high temperature and high pressure of 1200 ° C, 2 MPa, containing 4.0% O 2 of gas. The high-temperature and high-pressure gas p...

Embodiment 2

[0059] Using long-flame coal with a volatile content of more than 20% as raw material, in the carbonization and topping technology of young coal types in technology module I, the long-flame coal is crushed and sieved to obtain 30-50mm fragments, which are loaded into the low-temperature carbonization furnace After drying in the preheating section at 200°C, the dried coal block enters the dry distillation section at about 600°C for dry distillation. After dry distillation, it passes through the cooling section to obtain solid semi-coke, crude gas, crude benzene, crude naphthalene, tar, etc. Then the semi-coke is crushed in the technical module II oxygen-enriched direct combustion system to prepare the high-temperature gas turbine working medium, and enters the combustion chamber, where it is directly burned in a pure oxygen atmosphere to obtain a high temperature and high pressure of 1300 ° C, 4 MPa, containing 3.0% O 2 of gas. The high-temperature and high-pressure gas passes ...

Embodiment 3

[0062] Using non-caking coal with a volatile content of about 25-30% as raw material, in technology module I dry distillation of young coal types, non-caking coal is crushed and sieved to obtain 100-120mm fragments, which are loaded into low-temperature carbonization After the furnace, it goes through a preheating section at 180°C for drying, and the dried coal block enters a dry distillation section at about 800°C for dry distillation. After dry distillation, the solids pass through a cooling section to obtain semi-coke, crude gas, crude benzene, crude naphthalene, tar, etc. Then the semi-coke enters the technical module II oxygen-enriched direct combustion to prepare the high-temperature gas turbine working fluid system. The semi-coke is crushed and then enters the combustion chamber, where it is directly burned in a pure oxygen atmosphere to obtain a high temperature and high pressure of 1100 ° C, 3 MPa, containing 5.0% O 2 of gas. The high-temperature and high-pressure gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com