Server packaging test line

A server and test line technology, applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of multiple packaging processes, low packaging efficiency, heavy server weight, etc., to protect personal safety, reduce work intensity, and improve safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

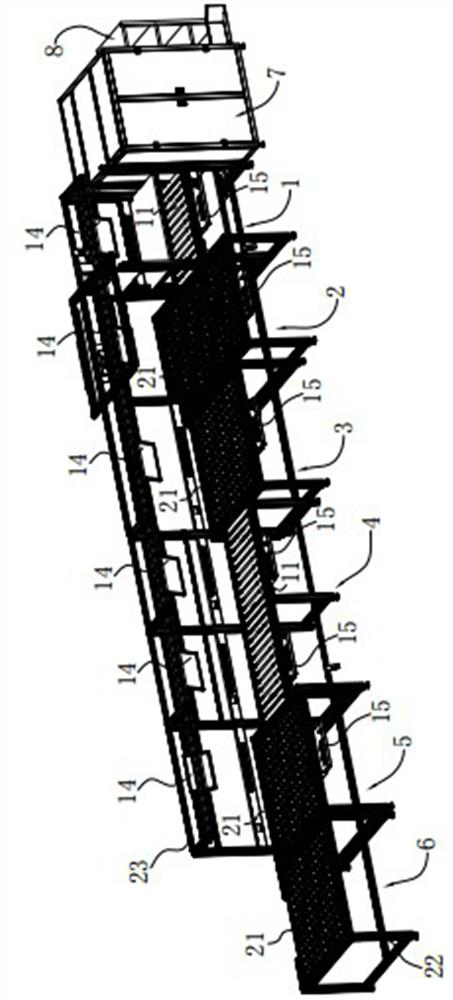

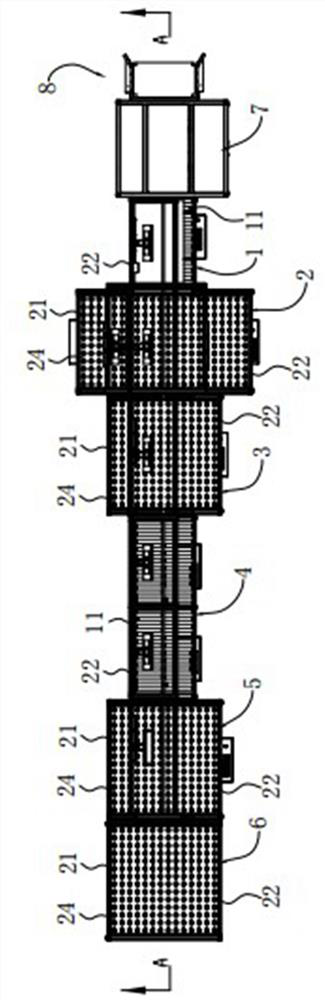

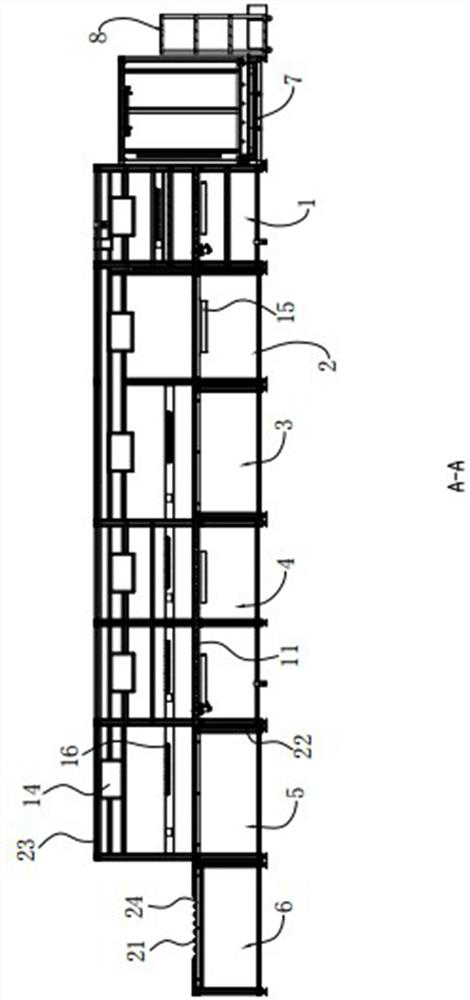

[0039] The following is attached Figure 1-6 The application is described in further detail.

[0040] The embodiment of the present application discloses a server packaging test line. refer to figure 1 and figure 2 A server packaging test line includes a safety test bench 1, a power-on test bench 2, an appearance inspection bench 3, an accessory installation bench 4, an overall quality inspection bench 5, and a packing bench 6, which are arranged in sequence and are located in the same horizontal plane. A number of non-powered rollers 11 are arranged on the gauge test platform 1 and the accessory installation platform 4 along the direction of their arrangement. There are several balls 21, and the rollers 11 on the safety test bench 1 and the accessory installation table 4, and the balls 21 on the power-on test bench 2, the appearance inspection bench 3, the overall quality inspection bench 5 and the packing bench 6 The top tangent planes are at the same level and are high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com