TPU modified PVC foaming material, artificial leather and preparation method of artificial leather

A foaming material and artificial leather technology, applied in the field of artificial leather, can solve the problems of poor wear resistance and cold resistance of the PVC artificial leather foam layer, and achieve the effect of soft touch, good elasticity and reducing the types of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

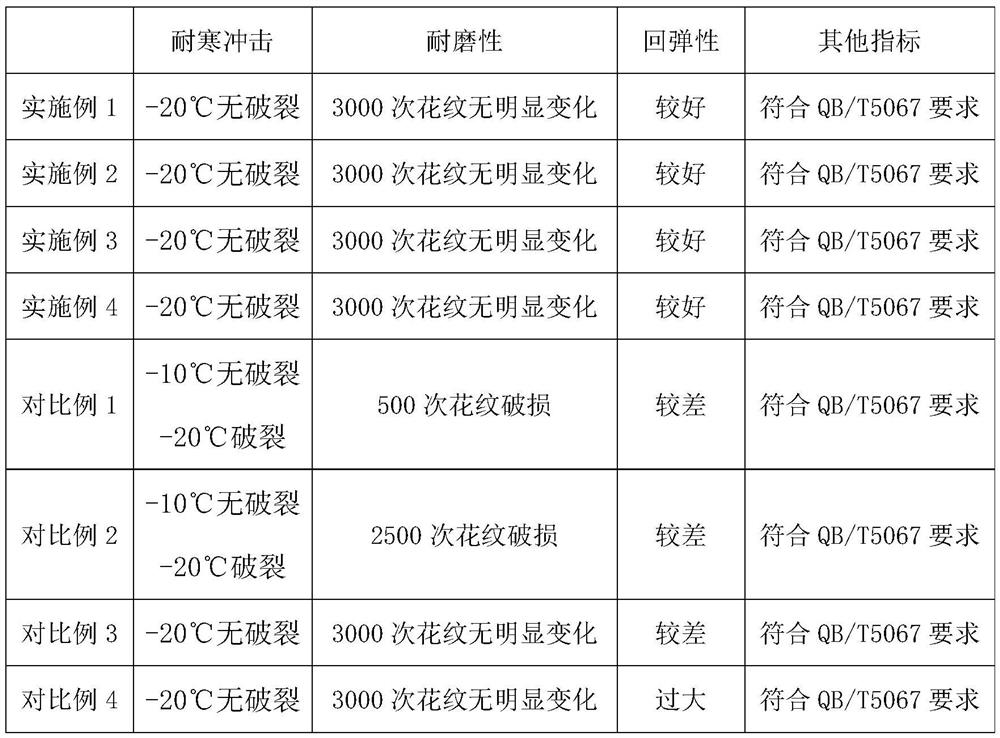

Examples

Embodiment 1

[0041] A TPU modified PVC foaming material comprises the following components in parts by weight: 50 parts of TPU, 70 parts of PVC, 70 parts of DOP, 3 parts of AC foaming agent, and 2 parts of calcium zinc stabilizer.

[0042] The degree of polymerization of the PVC is 1100.

[0043] The 100% modulus of the TPU is 7 MPa.

[0044] The Shore hardness of the TPU is 75A.

[0045] The prescription of above-mentioned TPU modified PVC foam material is used for preparing artificial leather, and the preparation method of artificial leather comprises the following steps:

[0046] Step S001. Foaming layer ingredients: use a high-speed mixer to mix TPU, PVC, DOP, AC foaming agent, and calcium-zinc stabilizer according to the ratio;

[0047] Step S002. Internal mixing: perform internal mixing and plasticizing the uniformly mixed foam layer components, and filter through an extruder;

[0048] Step S003. Calendering and patching: calendering the filtered foam layer mixture through a calen...

Embodiment 2

[0052] A TPU modified PVC foaming material comprises the following components in parts by weight: 20 parts of TPU, 50 parts of PVC, 100 parts of DOP, 1 part of AC foaming agent, and 3 parts of calcium zinc stabilizer.

[0053] The degree of polymerization of the PVC is 1000.

[0054] The 100% modulus of the TPU is 5 MPa.

[0055] The Shore hardness of the TPU is 95A.

[0056] The prescription of above-mentioned TPU modified PVC foam material is used for preparing artificial leather, and the preparation method of artificial leather comprises the following steps:

[0057] Step S001. Foaming layer ingredients: use a high-speed mixer to mix TPU, PVC, DOP, AC foaming agent, and calcium-zinc stabilizer according to the ratio;

[0058] Step S002. Internal mixing: perform internal mixing and plasticizing the uniformly mixed foam layer components, and filter through an extruder;

[0059] Step S003. Calendering and patching: calendering the filtered foam layer mixture through a calen...

Embodiment 3

[0063] A TPU modified PVC foaming material comprises the following components in parts by weight: 40 parts of TPU, 100 parts of PVC, 40 parts of DOP, 2 parts of AC foaming agent, and 1 part of calcium zinc stabilizer.

[0064] The degree of polymerization of the PVC is 1000.

[0065] The 100% modulus of the TPU is 10 MPa.

[0066] The Shore hardness of the TPU is 82A.

[0067] The prescription of above-mentioned TPU modified PVC foam material is used for preparing artificial leather, and the preparation method of artificial leather comprises the following steps:

[0068] Step S001. Foaming layer ingredients: use a high-speed mixer to mix TPU, PVC, DOP, AC foaming agent, and calcium-zinc stabilizer according to the ratio;

[0069] Step S002. Internal mixing: perform internal mixing and plasticizing the uniformly mixed foam layer components, and filter through an extruder;

[0070] Step S003. Calendering and patching: calendering the filtered foam layer mixture through a cale...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com