Negative ion underwear fabric and preparation process thereof

A technology for underwear fabrics and negative ions, which can be applied to underwear, wear-resistant fibers, and improved hand-feeling fibers. It can solve the problems of uneven quality of fabrics that can release negative ions, the surface of fabrics is not smooth enough, and affects wearing comfort. Achieve good wear resistance and antibacterial effect, increase health care performance, and achieve high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

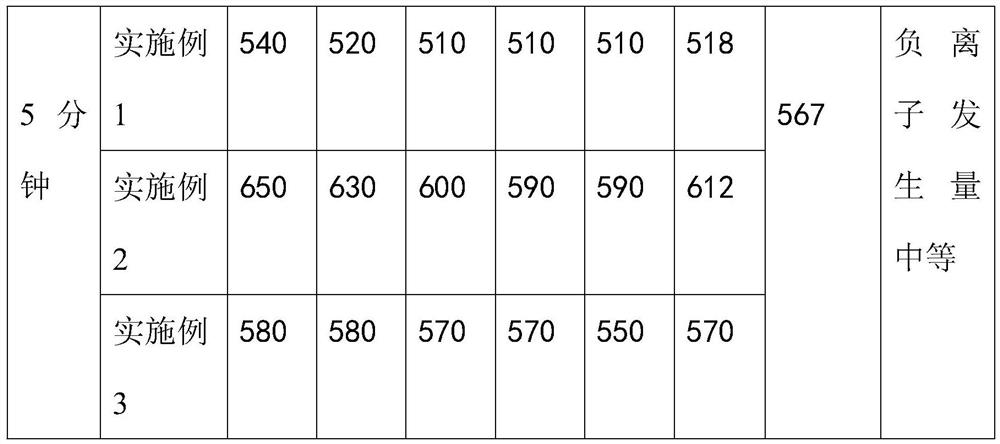

Embodiment 1

[0020] A kind of negative ion underwear fabric, comprises the following raw material of weight kilogram: Nylon 80, spandex 15, diatom powder 2, tourmaline 1, softening agent 0.5, dispersant 0.5, microcrystalline cellulose 1.

[0021] The preparation technology of negative ion underwear fabric of the present invention comprises the following steps:

[0022] 1) Weigh nylon and spandex according to the prescribed ratio and wash them in a solvent. During the cleaning process, the solution is stirred. After cleaning, nylon and spandex are placed in a drying chamber for drying;

[0023] 2) put the dried nylon and spandex into the hot-melt device for hot-melt treatment, and take intermittent stirring during the hot-melt processing to finally obtain a mixture;

[0024] 3) Process the mixture obtained in step 2) with a spinning device, recover the processed silk thread during the spinning process, and wind it on a roll for collection;

[0025] 4) Place the silk thread wound on the rol...

Embodiment 2

[0030] A kind of negative ion underwear fabric, comprises following raw material of weight kilogram: Nylon 75, spandex 20, diatom powder 2, tourmaline 1, softener 1, dispersant 0.5, microcrystalline cellulose 0.5.

[0031] The preparation process of the negative ion underwear fabric described in this embodiment is the same as that in Example 1.

Embodiment 3

[0033] A kind of negative ion underwear fabric, comprises following raw material of weight kilogram: Nylon 77, spandex 18, diatom powder 2, tourmaline 1, softener 1, dispersant 0.5, microcrystalline cellulose 0.5.

[0034] The preparation process of the negative ion underwear fabric described in this embodiment is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com