A general-purpose mechanical seal capable of dry grinding, anti-bonding, strong corrosion resistance and high temperature resistance

A general-purpose mechanical and anti-adhesive technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of electric energy waste, friction pair damage, and high cost, so as to expand the scope of use, reduce electric energy waste, and reduce electrode The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

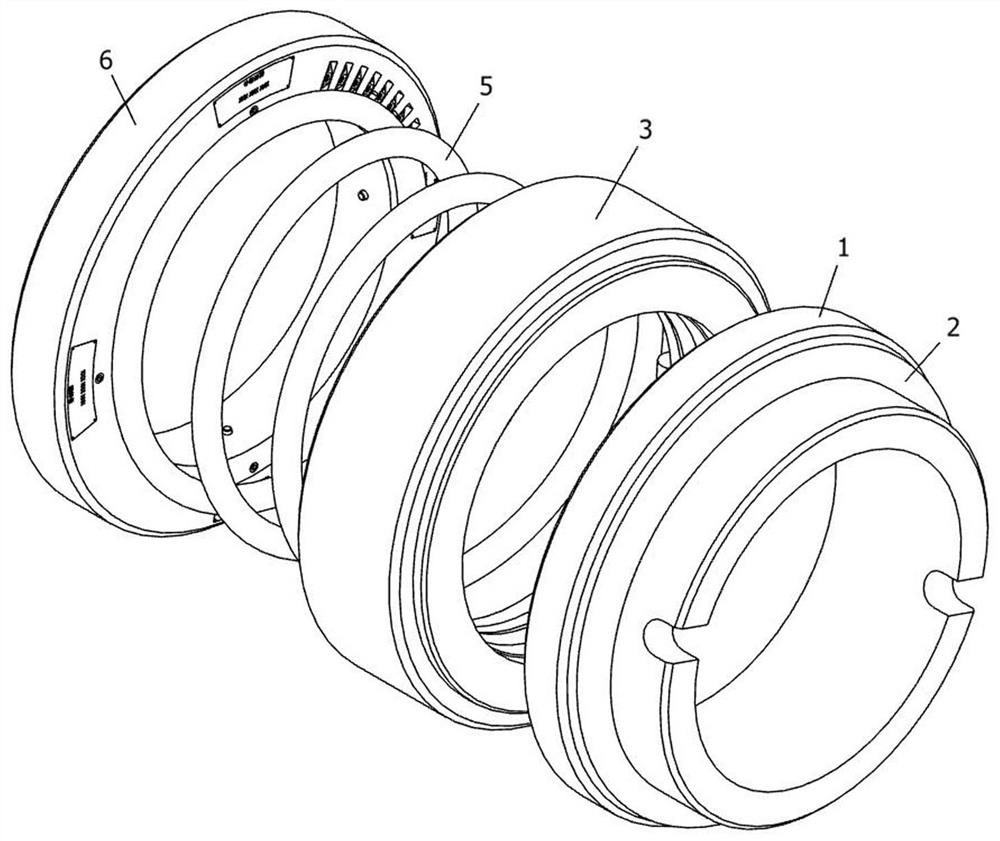

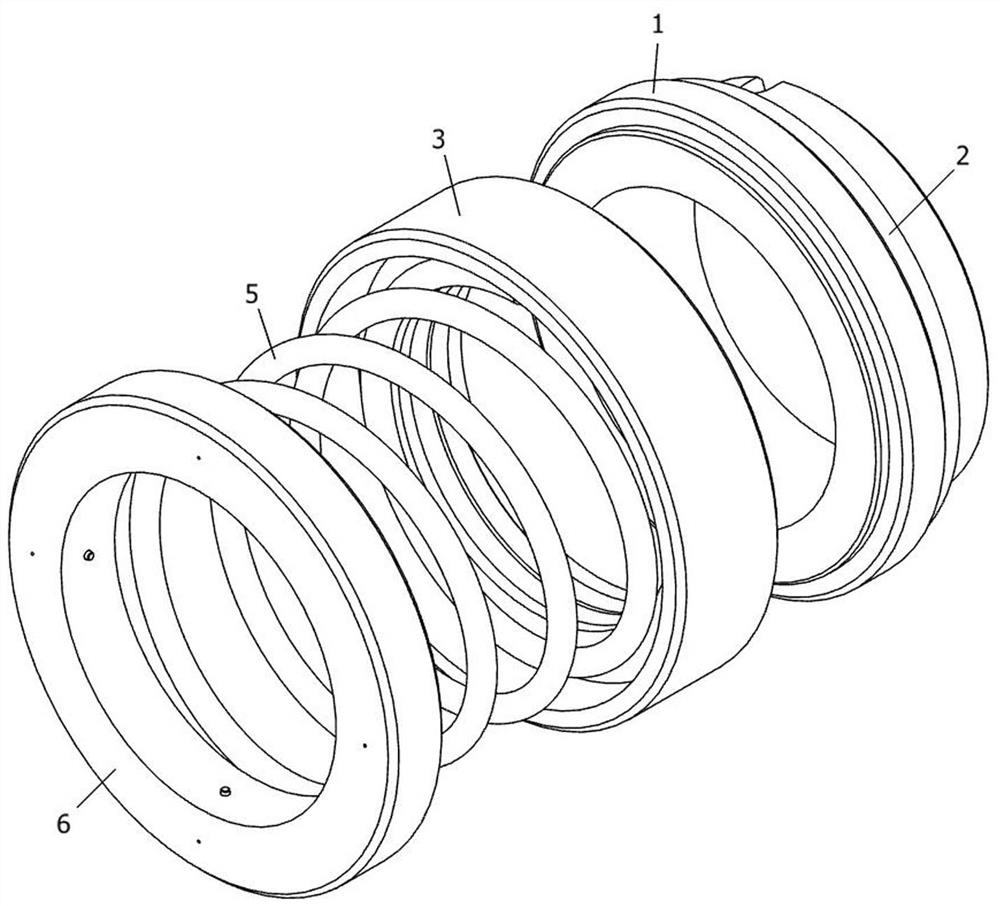

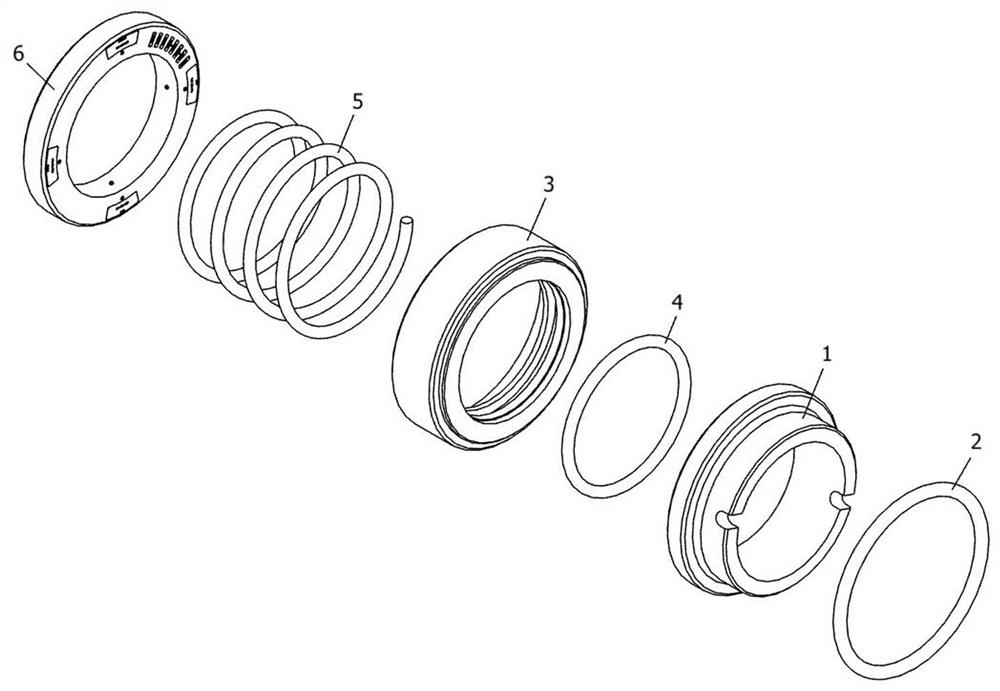

[0044] Example: Please refer to Figure 1 to Figure 9 :

[0045] The present invention proposes a general mechanical seal capable of dry grinding, anti-bonding, strong corrosion resistance and high temperature resistance, comprising: a static ring 1, a static sealing ring 2 is sleeved on the static ring 1, and a moving ring 3 is arranged behind the static ring 1, A dynamic sealing ring 4 is clamped inside the moving ring 3, a spring seat 6 is arranged behind the moving ring 3, a compensation spring 5 is arranged between the spring seat 6 and the moving ring 3, and the two ends of the compensation spring 5 are connected to the spring seat 6 and the moving ring respectively. The rings 3 are in contact; the static ring 1 is made of silicon carbide, and a pore-forming agent is added during the manufacture of the static ring 1; the front end of the spring seat 6 is in an annular array, and the compensation spring identification plate 601 and the static ring identification plate are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com