Device and method for calibrating and measuring temperature of inner wall of thin-wall hollow circular tube

A technology of measuring devices and hollow circles, which is applied to measuring devices, thermometers, measuring heat, etc., can solve the problems that the fluid-solid coupling finite element simulation technology is difficult to obtain accurate results, and the cooling gas and the temperature measuring device do not interfere with each other, so as to eliminate The effect of evenly distributing the turbulence of the cooling gas and improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

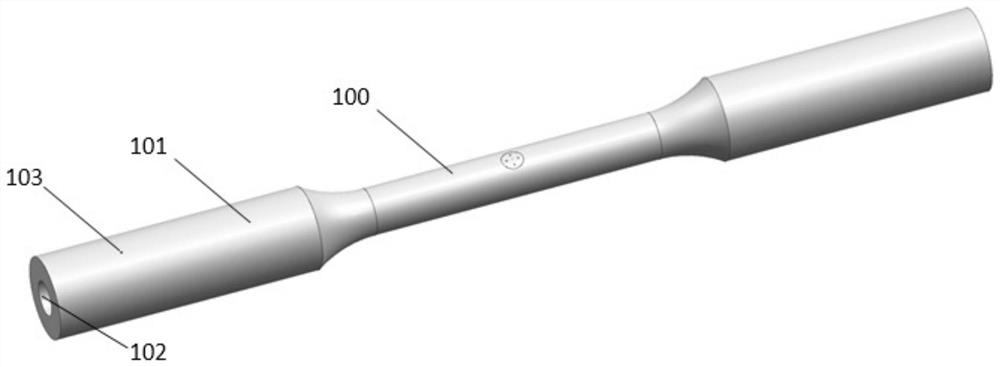

[0039] Embodiment 1, providing a thin-walled hollow tube inner wall temperature calibration measurement device, the thickness of the thin-walled hollow tube is ≤ 2mm, the calibration test piece is used in the calibration measurement method, and the center of the calibration test piece is a thin-walled hollow tube 100 , the two ends of the calibration test piece are round tube installation ends 101; the center of the calibration test piece is a continuous smooth hollow circular lumen 102; at least one round tube installation end has a temperature measurement hole 103, and the temperature measurement hole 103 is used For measuring the lumen temperature of the corresponding round tube installation end 101;

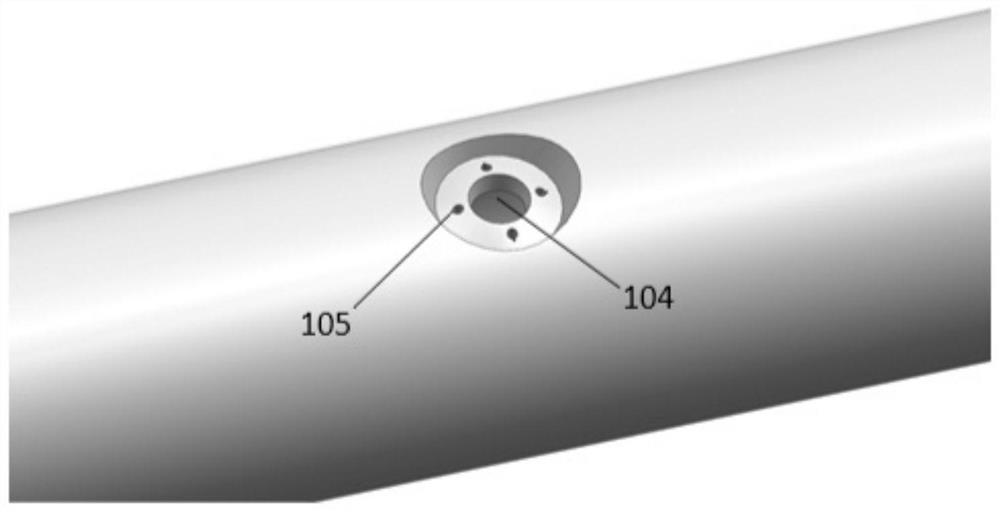

[0040] The thin-walled hollow tube 100 has a step through hole 104, the upper opening of the step through hole 104 is gradually expanding, and the shape of the upper opening is non-circular, and the step surface of the step through hole 104 has multiple a pin hole 105;

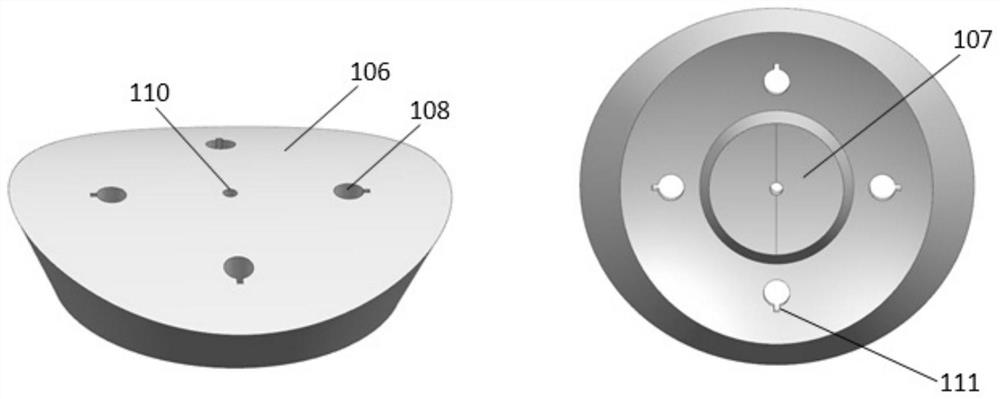

[00...

Embodiment 2

[0057] Embodiment 2, providing a thin-walled hollow tube inner wall temperature calibration measurement device, the thickness of the thin-walled hollow tube is ≤ 2mm, the calibration test piece is used in the calibration measurement method, and the center of the calibration test piece is a thin-walled hollow tube 100 , the two ends of the calibration test piece are round tube installation ends 101; the center of the calibration test piece is a continuous smooth hollow circular lumen 102; at least one round tube installation end has a temperature measurement hole 103, and the temperature measurement hole 103 is used For measuring the lumen temperature of the corresponding round tube installation end 101;

[0058] The thin-walled hollow tube 100 has a step through hole 104, the upper opening of the step through hole 104 is gradually expanding, and the shape of the upper opening is non-circular, and the step surface of the step through hole 104 has multiple a pin hole 105;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap