Walnut cleaning equipment

A technology for cleaning equipment and walnuts, applied in the fields of application, food science, food processing, etc., can solve the problems of walnuts prone to mold and waste of water resources, and achieve the effects of reducing pollution, saving costs and sites, and ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following embodiments in conjunction with the accompanying drawings are only intended to illustrate the technical solutions described in the claims, and are not intended to limit the scope of protection of the claims.

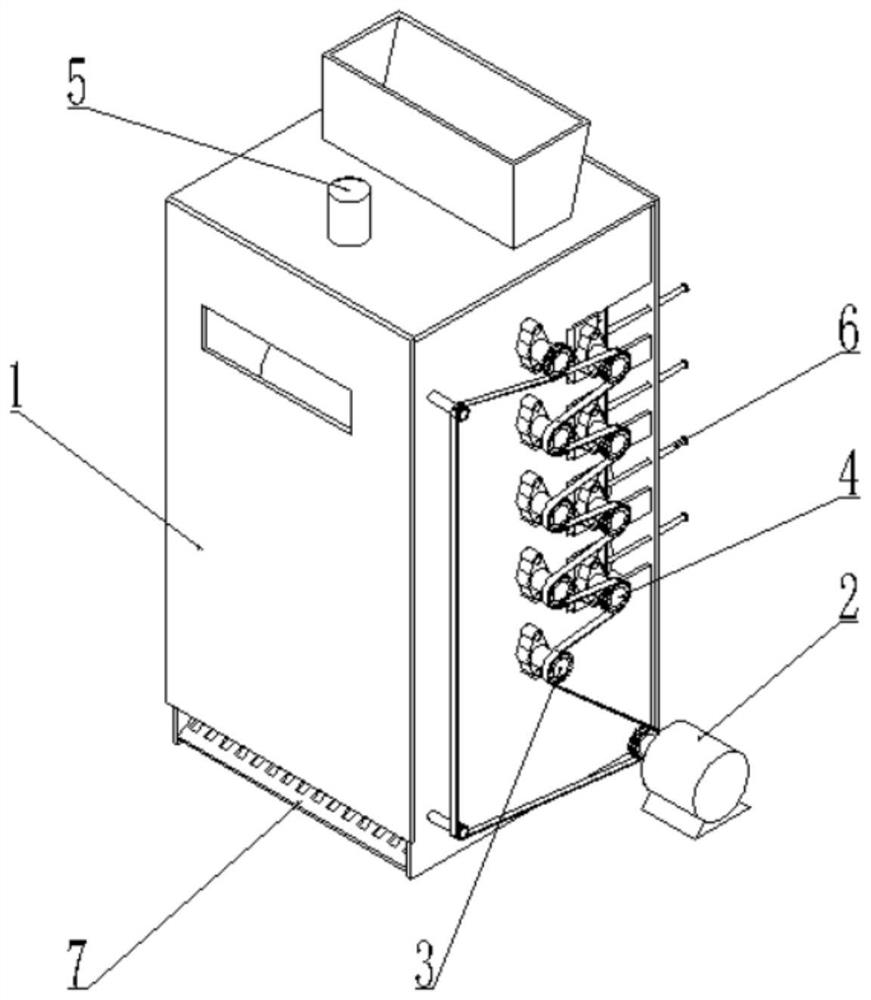

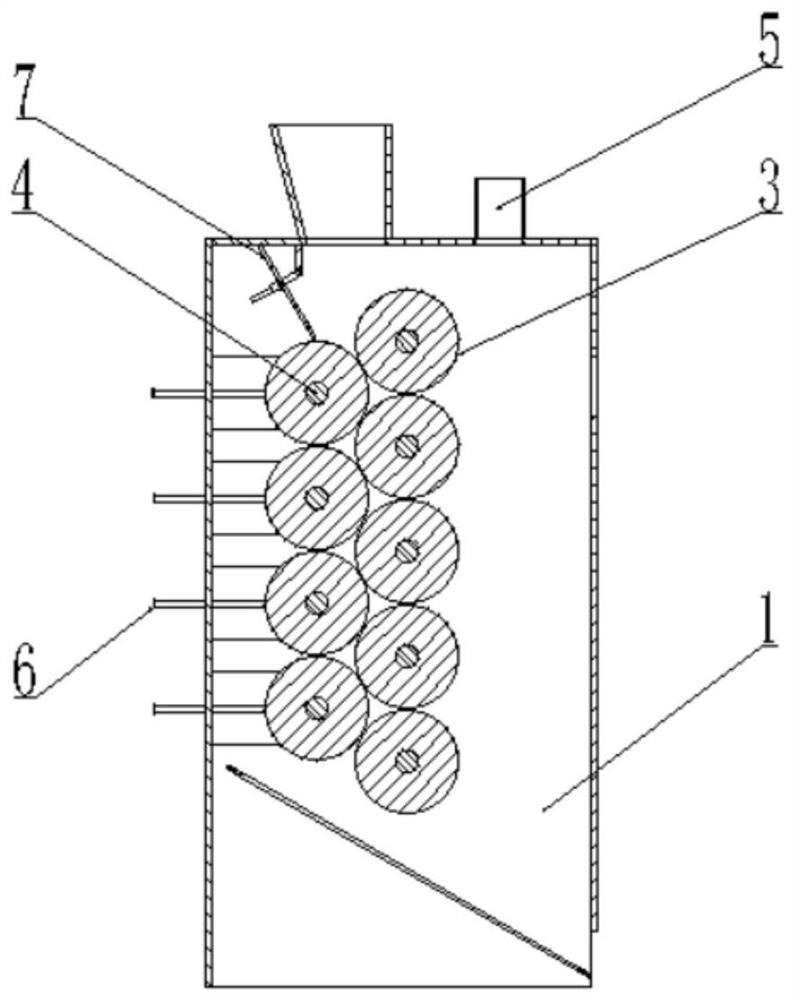

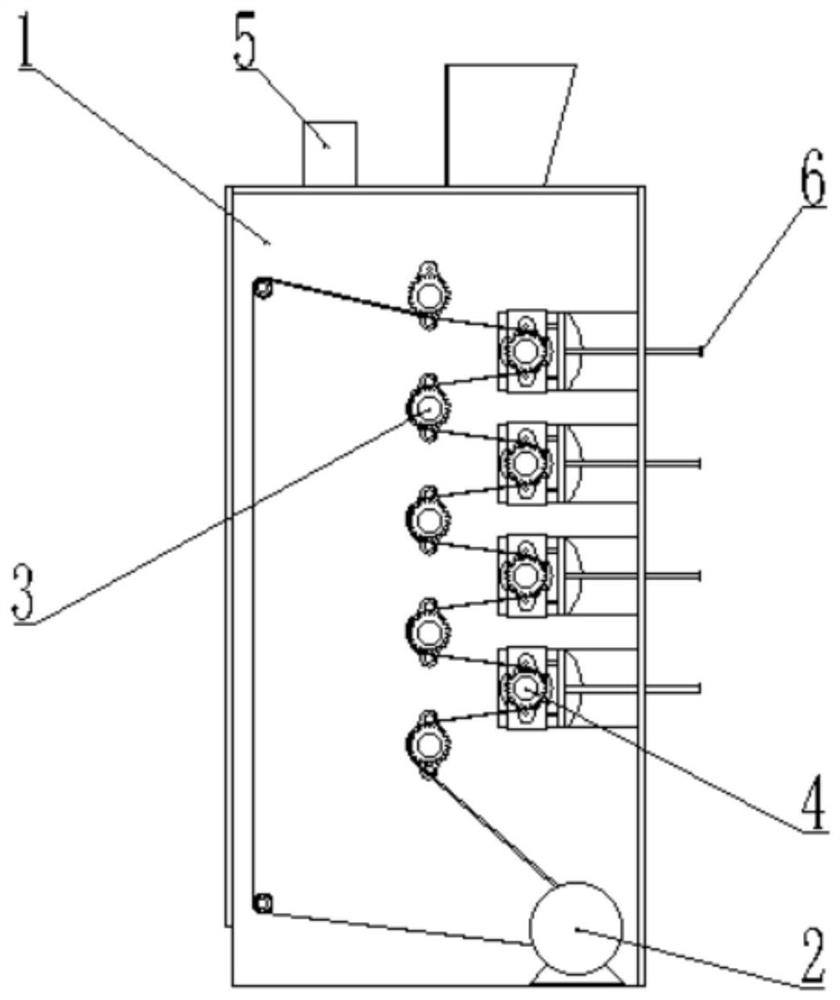

[0026] combined with Figure 1-5 , a kind of walnut cleaning equipment, comprises the frame 1 that has feed inlet, and the roller brush group that is installed in the frame 1, and described roller brush group is the inner roller brush row and the outer roller brush row that rotate in opposite directions; The roller brush A 3 of the inner roller brush row and the roller brush B 4 of the outer roller brush row are nylon brush rollers, and the diameter of the bristles is D, 0.2mm≤D≤0.4mm, and the length of the bristles is L, 0< L≤40mm, the optimal length of the bristles is 35mm; the frame 1 is a box type, and the top of the frame 1 is also provided with a dust removal air duct 5, which is used to connect with the fan to extract the dust generated in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com