Tower plate, reactive distillation device and preparation method of peroxycarboxylic acid

A technology of peroxycarboxylic acid and reactive distillation, applied in the field of reactive distillation, can solve problems such as explosion and safety accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

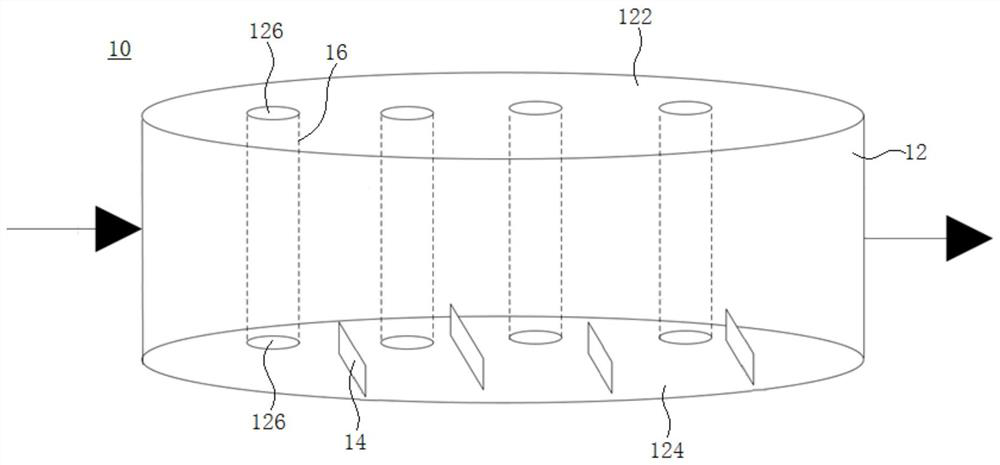

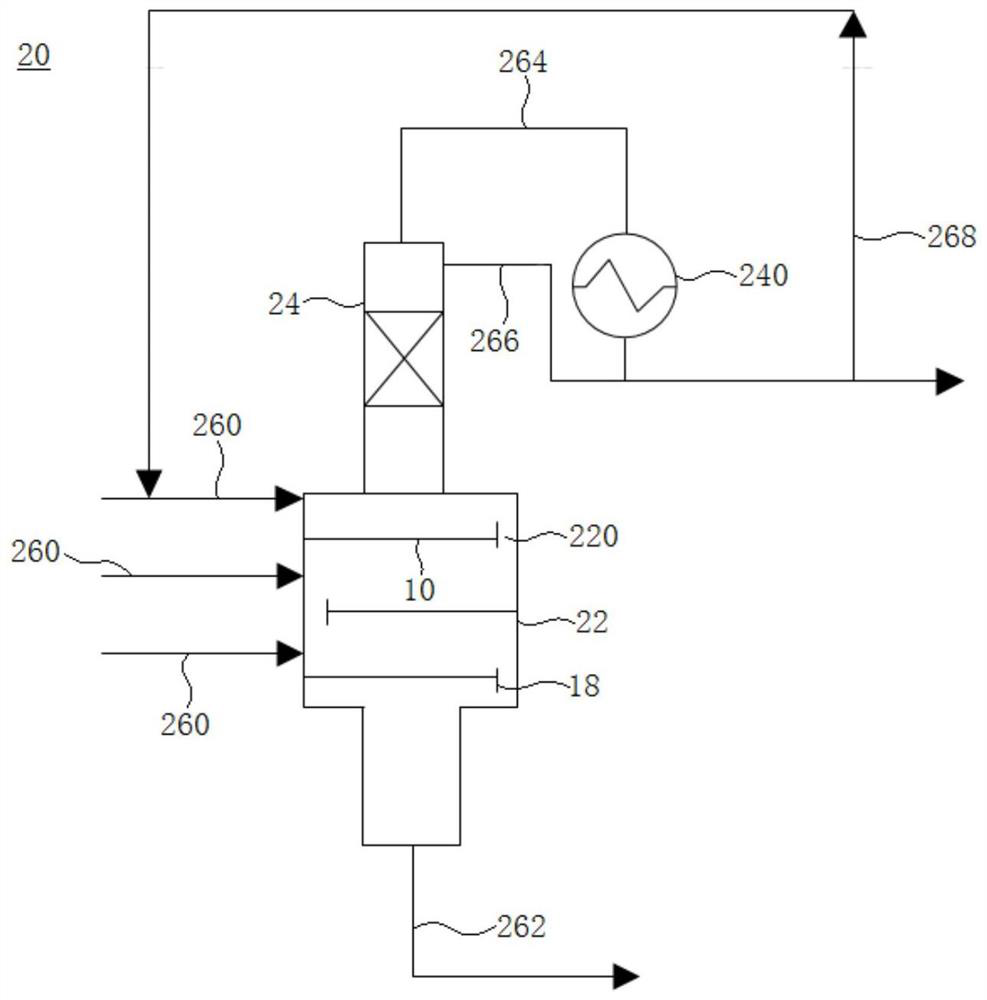

[0054] The present invention provides a kind of preparation method of peroxycarboxylic acid again, preferably, can utilize the reactive distillation device 20 provided by the present invention to carry out reaction, the preparation method of peroxycarboxylic acid comprises the following steps: Step S10: the first The reactant and the second reactant are mixed to form a reaction material, wherein; the first reactant is one or more of carboxylic acid and acid anhydride, and the second reactant is an oxidant; Step S20: select heat exchange medium and The reaction material is subjected to heat exchange so that the reaction material reaches a preset temperature, and under the preset temperature condition, a mixture containing peroxycarboxylic acid is obtained by reaction, for example, the heat exchange medium can heat the reaction material , so that the reaction material is at a preset temperature, thus, the reaction material can reach a preset temperature by exchanging heat with th...

Embodiment 1

[0068] Example 1 Preparation of Peracetic Acid

[0069] use figure 2 The shown reactive distillation unit 20 prepares peracetic acid, wherein: 10 trays 10 are arranged at intervals along the height direction of the shell 22, and a gap is left between the tray 10 and the inner wall of the shell 22 to form an overflow port, wherein , the tray 10 includes a tray body 12 with a receiving surface 122 capable of receiving the reaction materials, the tray body 12 is provided with a chamber for the circulation of the heat exchange medium for exchanging heat with the reaction materials, and the tray body 12 is provided with The inlet and outlet for the heat exchange medium to enter and exit the chamber respectively, the bottom surface 124 and the receiving surface 122 of the tray body 12 opposite to the receiving surface 122 are provided with through holes 126, and the thickness of the tray body 12 is 0.4 m, the receiving surface 122 of the tray body 12 is provided with a catalyst ...

Embodiment 2

[0075] Example 2 Preparation of Peracetic Acid

[0076] use figure 2 The shown reactive distillation unit 20 prepares peracetic acid, wherein: along the height direction of the shell 22, 15 trays 10 are arranged at intervals, and a gap is left between the tray 10 and the inner wall of the shell 22 to form an overflow port, wherein , the tray 10 includes a tray body 12 with a receiving surface 122 capable of receiving the reaction materials, the tray body 12 is provided with a chamber for the circulation of the heat exchange medium for exchanging heat with the reaction materials, and the tray body 12 is provided with The inlet and outlet for the heat exchange medium to enter and exit the chamber respectively, the bottom surface 124 and the receiving surface 122 of the tray body 12 opposite to the receiving surface 122 are provided with through holes 126, and the thickness of the tray body 12 is 0.75 m, the receiving surface 122 of the tray body 12 is provided with a catalys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com