Sewage treatment equipment for ctp plate production

A technology of sewage treatment equipment and plates, applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult cleaning, large water consumption, and increased workload due to removal of filter screens and other problems to achieve good cleaning effect and avoid long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with accompanying drawing

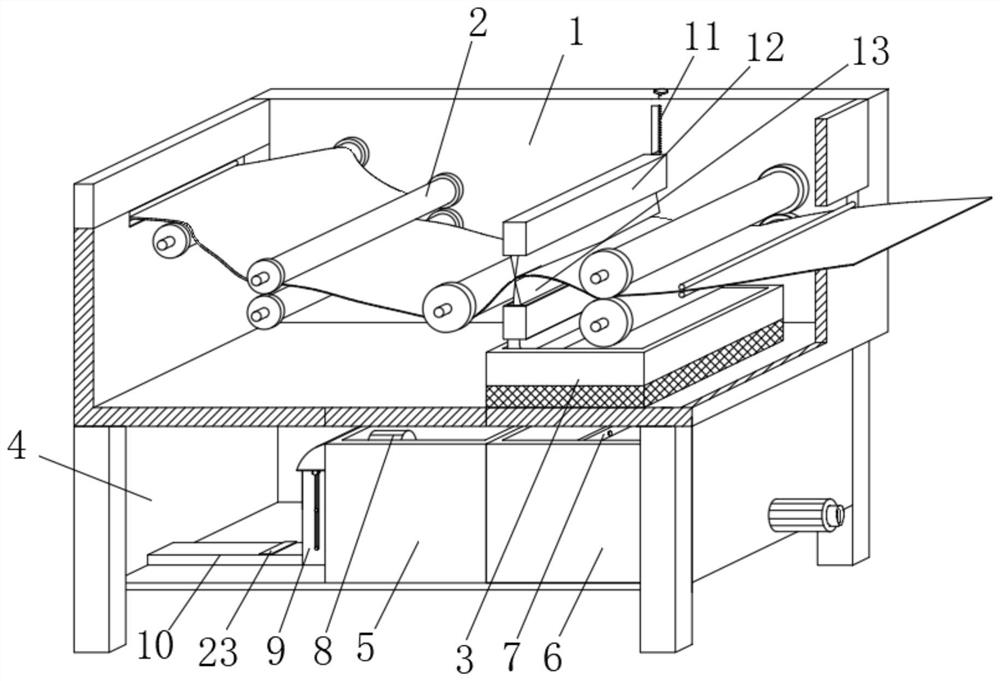

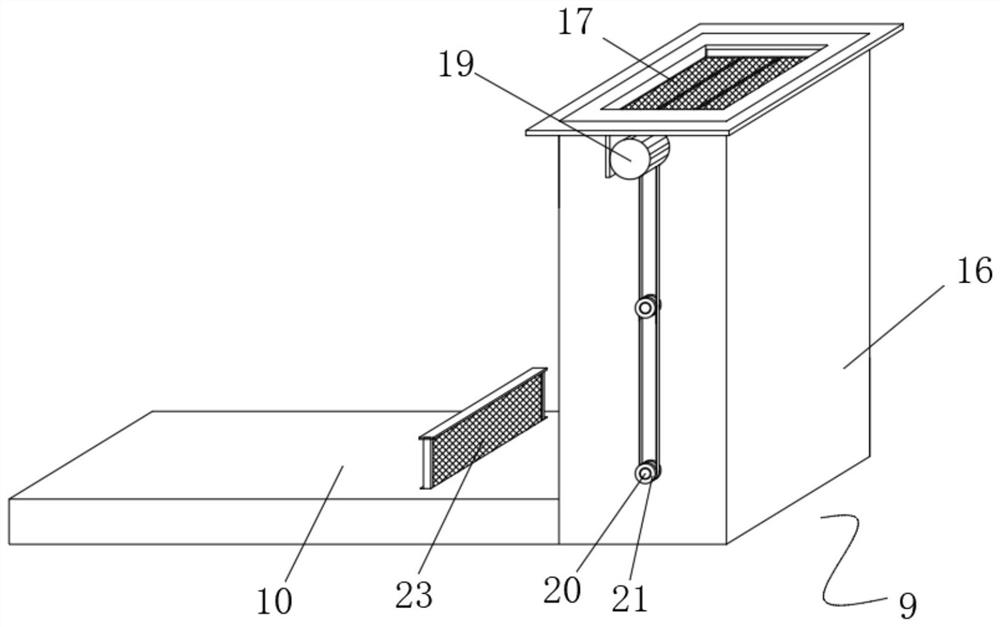

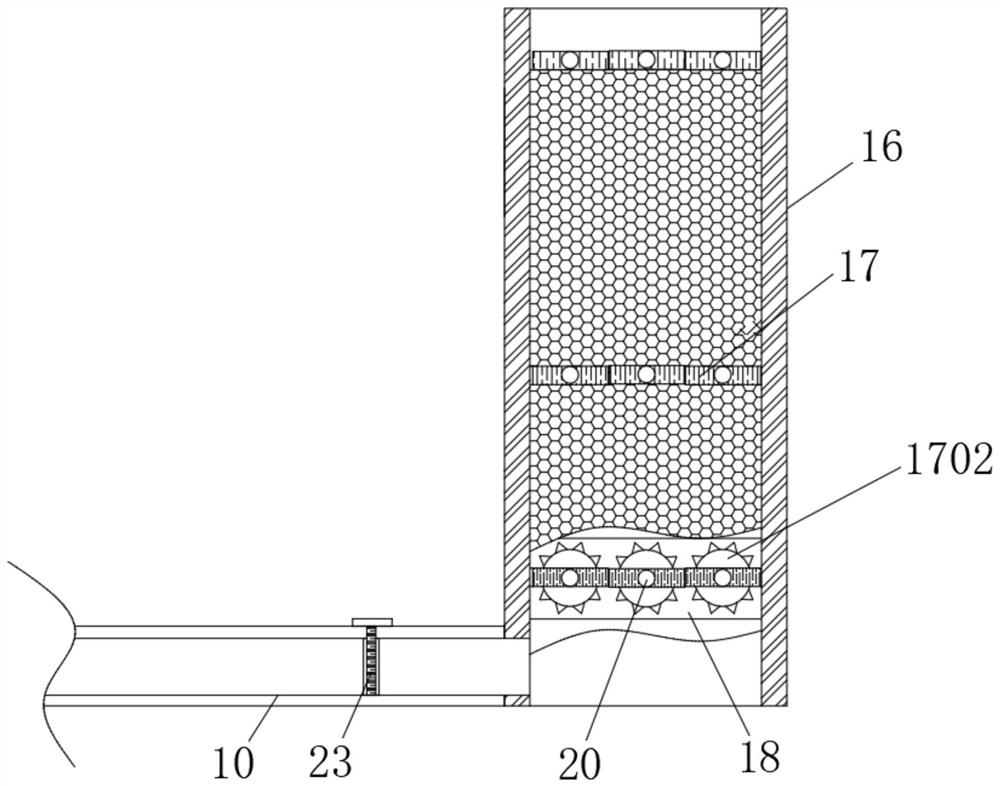

[0028] see Figure 1~6 , in the embodiment of the present invention, a sewage treatment equipment for ctp plate production, including a cleaning box 1, the inner wall of the cleaning box 1 is provided with an adjustable scraper assembly, and the inner wall of the cleaning box 1 is also provided with a number of cleaning Roller 2, the bottom of the inner wall of the cleaning box 1 is also provided with a waste discharge tank 3 below the scraper assembly, the bottom of the cleaning box 1 is provided with a treatment box 4, and the bottom of the treatment box 4 is provided with a drain valve for cleaning the cleaning box 1 The internal sewage is discharged into the sedimentation tank 6. The inner wall of the treatment tank 4 is provided with a clean water tank 5 and a sedimentation tank 6 from left to right. The sedimentation tank 6 is located directly below the waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com