Disassembling method for rivets on composite material closed tubular beam

A technology of composite materials and closed tubes, applied in cleaning methods and utensils, chemical instruments and methods, hand-held tools, etc., can solve problems such as weak bonding interface, large number of holes, and low success rate, and achieve residual and The risk of failure is low, the tool requirements are simple, and the implementation effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with the examples, but it should be understood that these descriptions are only for further illustrating the features and advantages of the present invention rather than limiting the patent requirements of the present invention.

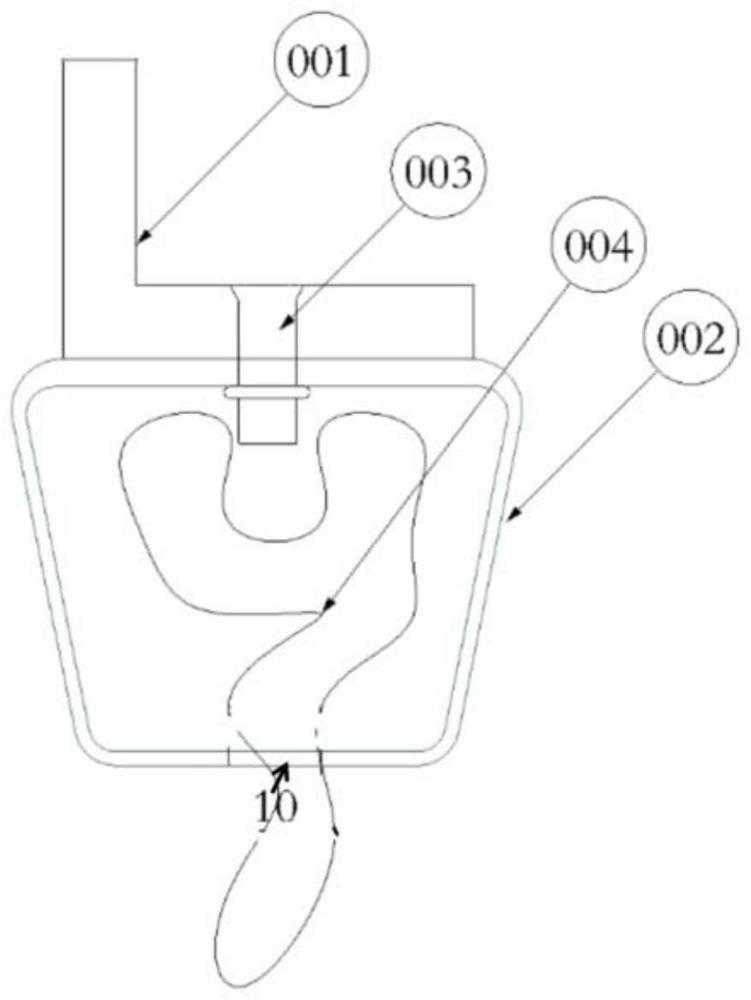

[0039] The main technical idea adopted in the present invention is: by pre-placing an adhesive strip with suitable adhesive performance and physical state on the back of the riveted rivet, the surplus materials such as pier head and debris generated by the decomposition of the rivet can be fixed in the adhesive strip rather than falling into the tube beam part. like figure 1 As shown, the connection bracket 001, the closed pipe beam 002, the rivet 003, and the adhesive strip 004. The specific implementation steps are:

[0040] 1. Determine the location of the maintenance hole

[0041] Determine the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com