Low-cost low-precipitation PVC-U drain pipe material and preparation method thereof

A PVC-U, low-cost technology, applied to the low-cost and low-precipitation PVC-U drainage pipe material and the field of its preparation, can solve the problem of high formula cost, achieve low formula cost, less waste and residues, and reduce production costs Effect

Pending Publication Date: 2022-03-01

LIANSU TECH DEV WUHAN

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The primary purpose of the present invention is to overcome the problem of precipitation in the production process of PVC-U drainage pipe material in the prior art or the high cost of the existing anti-separation PVC-U drainage pipe material formula, and provide a low-cost and low-precipitation PVC-U drain pipe material

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~8

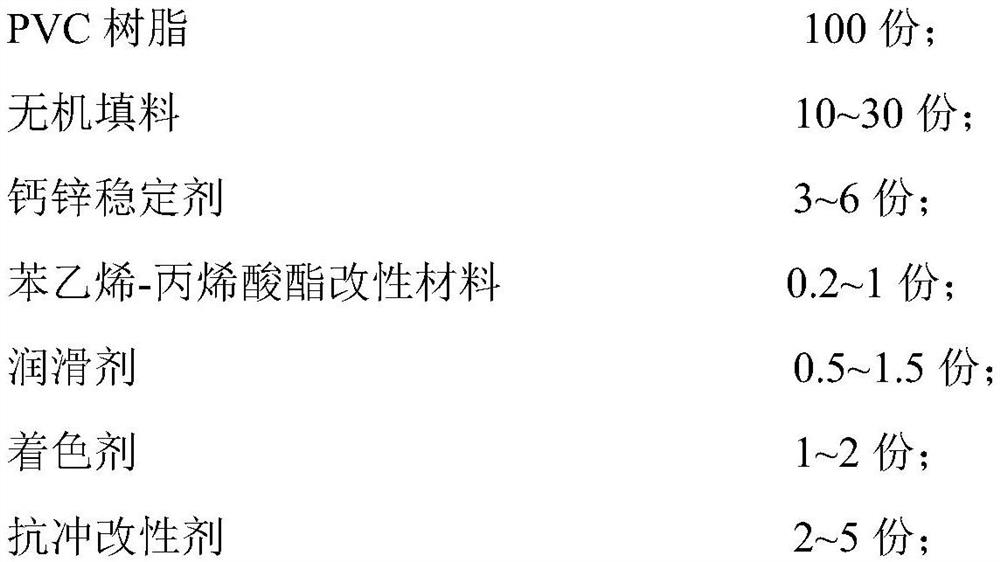

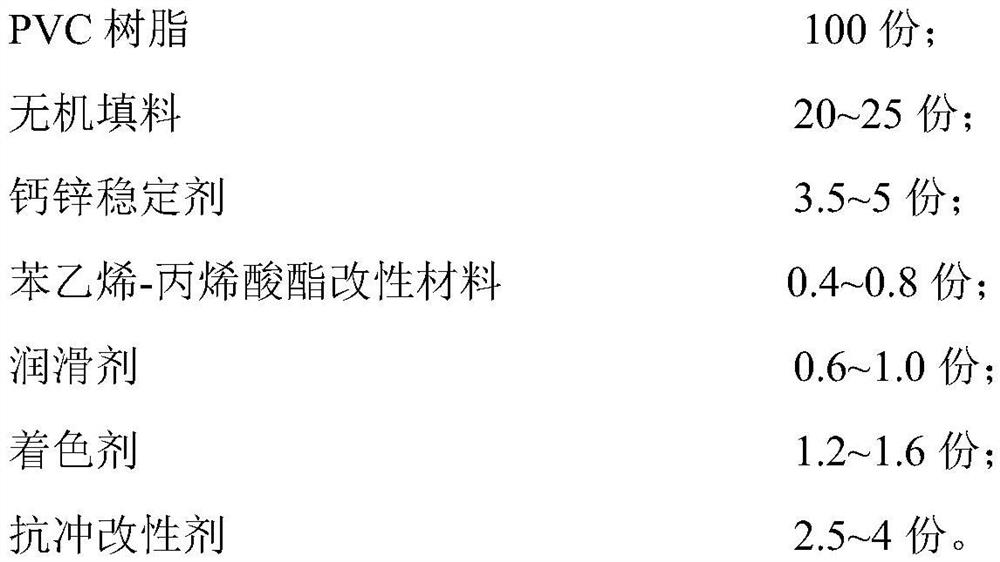

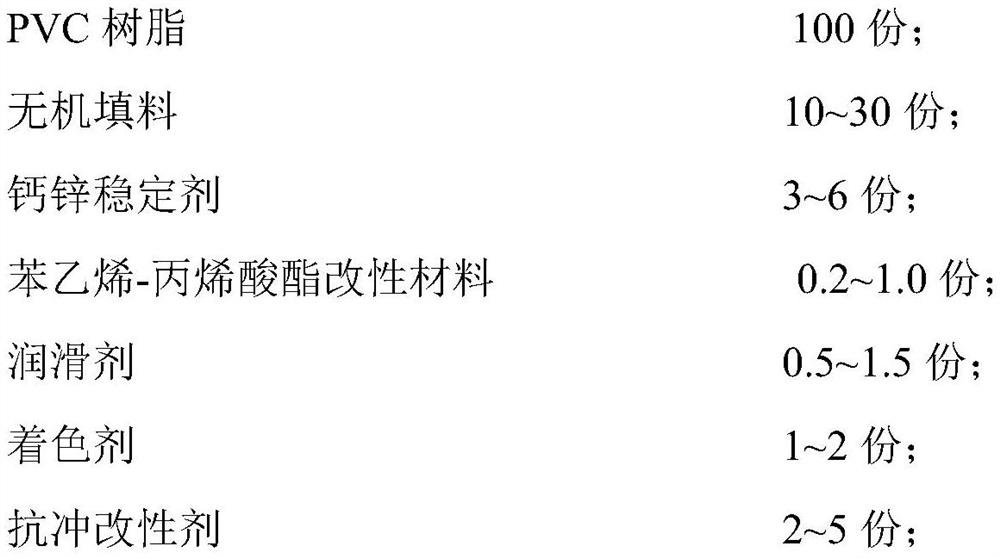

[0074] Examples 1-8 provide a series of PVC-U drainage pipe materials, the formulations of which include the components shown in Table 2 in parts by weight.

[0075] The formula of table 2 embodiment 1~8

[0076]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a low-cost and low-precipitation PVC-U drain pipe material and a preparation method thereof. The low-cost and low-precipitation PVC-U drain pipe material comprises the following components in parts by weight: 100 parts of PVC resin; 10-30 parts of an inorganic filler; 3-6 parts of a calcium-zinc stabilizer; 0.2 to 1 part of a styrene-acrylate modified material; 0.5 to 1.5 parts of a lubricant; 1-2 parts of a coloring agent; and 2-5 parts of an impact modifier. According to the low-cost and low-precipitation PVC-U drain pipe material, the precipitation condition is greatly improved in the production process, the production mold cleaning period is prolonged, the shutdown frequency is reduced, the energy consumption and the product rejection rate are reduced, meanwhile, the formula cost is low, and the economic benefits of enterprises are guaranteed.

Description

technical field [0001] The invention relates to the technical field of polymer materials, in particular to a low-cost and low-precipitation PVC-U drainage pipe material and a preparation method thereof. Background technique [0002] PVC-U drainage pipe has excellent physical and chemical properties, chemical corrosion resistance, high impact strength, small fluid resistance, 30% higher flow rate than cast iron pipe with the same diameter, aging resistance, long service life, and the service life is not less than 50 years. Ideal material for water supply and drainage. The production formula of PVC-U drainage pipes uses PVC resin as the main material, and at the same time it is mixed with other additives such as stabilizers, lubricants, and impact-resistant agents. In recent years, in order to comply with the new situation of environmental protection, calcium zinc stabilizers have been widely used in the production formula of PVC-U drainage pipes instead of lead salt stabiliz...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L27/06C08L25/14C08L23/30C08K9/04C08K3/34C08K5/098C08K3/26

CPCC08L27/06C08L2203/18C08K2201/011C08K2003/265C08L25/14C08L23/30C08K9/04C08K3/346C08K5/098C08K3/26

Inventor 梅绮文乔晓辉孙秀慧

Owner LIANSU TECH DEV WUHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com