Efficient and accurate daily porcelain 3D soft silica gel transfer printing ink and application thereof

A soft silicone, daily-use technology, applied in the direction of ink, application, household utensils, etc., to achieve the effect of clear edges, high precision, and accurate colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

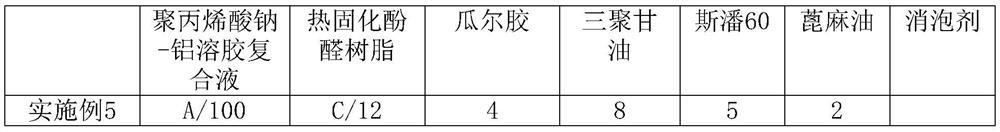

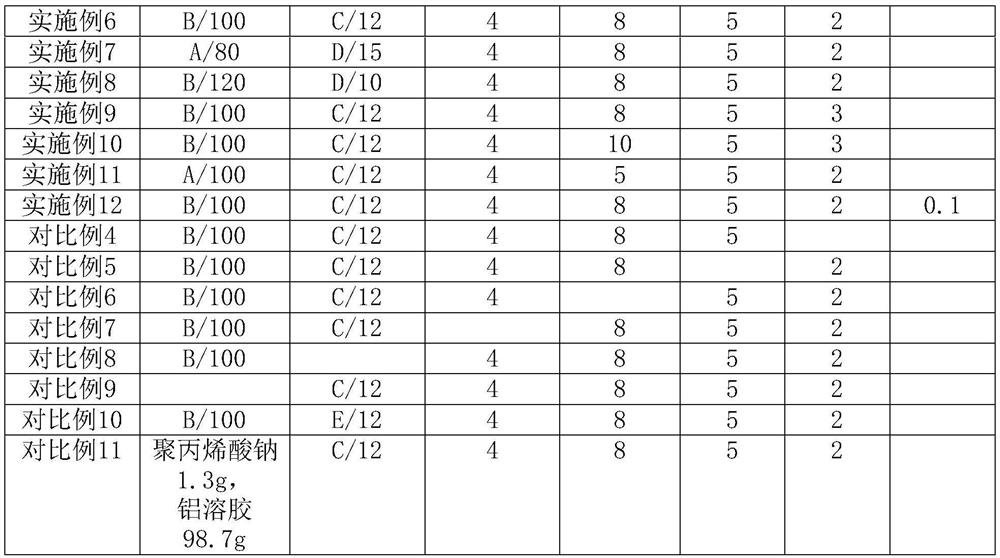

Examples

Embodiment 1

[0035] Prepare sodium polyacrylate-aluminum sol composite solution A as follows: In a stirred reactor, add sodium polyacrylate to room temperature water, beat until it becomes a glue, add aluminum isopropoxide and stir for 4 days to form a transparent light milky white glue , heated up to 80-85° C. and distilled under reduced pressure for 1 h until no isopropanol was left and the concentration of aluminum-containing sol was 12 m% based on alumina, and cooled to room temperature to obtain sodium polyacrylate-aluminum sol composite solution A. The mass ratio of ingredients is water, sodium polyacrylate, aluminum isopropoxide=120:1.3:30. The sodium polyacrylate used is XM-500 from Zhejiang Chunan Xumei Biotechnology Co., Ltd., with a degree of polymerization of 1200-1300. The purity of aluminum isopropoxide is over 99.9%.

[0036] The obtained sodium polyacrylate-aluminum sol composite solution A is transparent and light milky white, pH 8.1, and a clear optical path can be seen ...

Embodiment 2

[0038] Prepare sodium polyacrylate-aluminum sol composite liquid B basically according to the method of Example 1: In the same stirred reactor, add sodium polyacrylate to room temperature water, beat until it becomes a glue, add aluminum isopropoxide and stir for 5 days to form a transparent Warm up to 80-85°C and distill under reduced pressure for 1 hour until there is no residual isopropanol and the concentration of aluminum-containing sol is 15m% based on alumina, then cool to room temperature to obtain sodium polyacrylate-aluminum sol composite solution B. The mass ratio of ingredients is formulated according to water, sodium polyacrylate, aluminum isopropoxide = 120:2:50.

[0039] The obtained sodium polyacrylate-aluminum sol composite solution B is transparent and light milky white, pH 8.3, and a clear optical path can be seen when irradiated with thin beams of light, and the average particle diameter of aluminum sol is 8nm; it is stable and has no detectable change after...

Embodiment 3

[0045] Prepare thermosetting phenolic resin C as follows: In a stirred reactor, 37m% formaldehyde commercial aqueous solution is calculated as formaldehyde, phenol, and borax decahydrate are calculated as anhydrous matter, and the amount ratio of substances is 1.6:1:0.015. Formaldehyde solution, phenol ingredients, beating, heating up to 70°C and stirring for 15 minutes, adding a saturated aqueous solution of borax dropwise, raising the temperature to 85-90°C and maintaining this temperature for 3 hours, and then reacting under reduced pressure at 85-90°C for 1.5 hours to Sampling was carried out to detect that there was no formaldehyde, no phenol residue and about 35m% water, and cooled to room temperature to obtain heat-curable phenolic resin C.

[0046] The obtained heat-cured phenolic resin C is transparent and light brown-red; it is stable and has no visible change after being stored in airtight and light-shielding at room temperature for 3 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com