Preparation and application of strong-permeability moistening-enhancing material for coal seam water injection

A technology of coal seam water injection and distilled water, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of toxicity and corrosiveness, limited wetting ability of dust suppressants, and lack of environmental friendliness of dust suppressants, and achieves strong wetting ability. , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

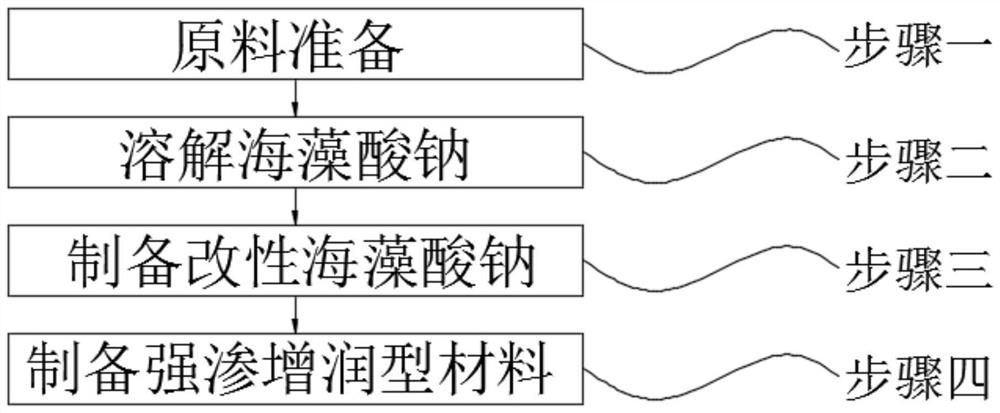

[0044] The preparation of a kind of enhanced penetration and wetting type material for coal seam water injection includes step 1, raw material preparation; step 2, dissolving sodium alginate; step 3, preparing modified sodium alginate; step 4, preparing strong penetration and enhancement type material;

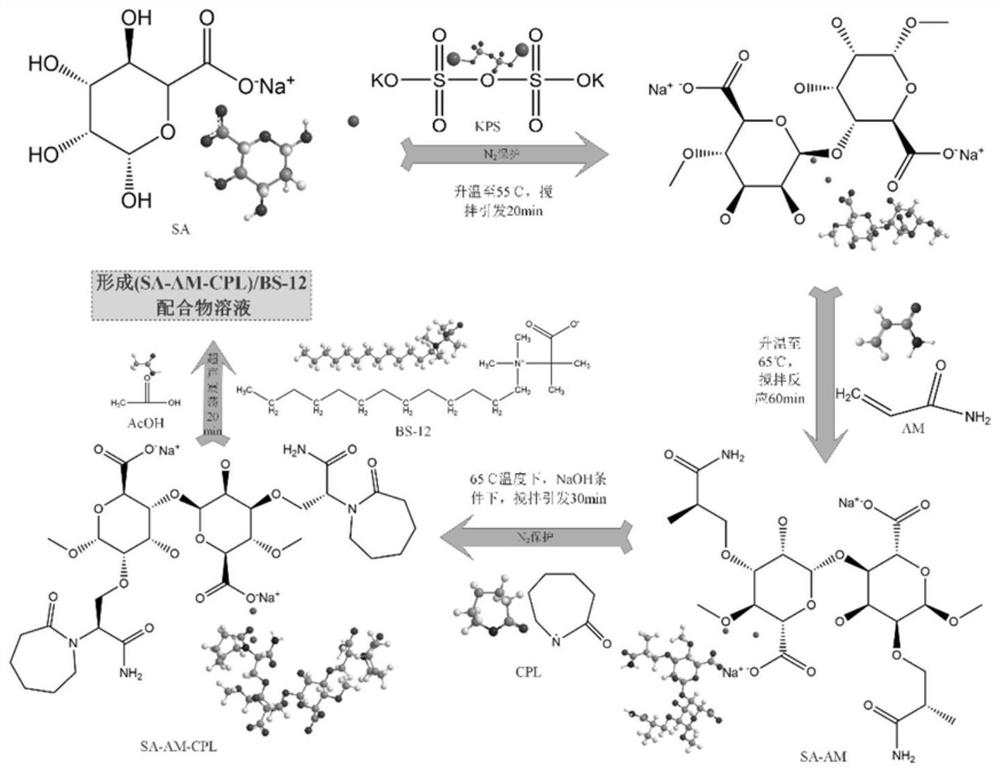

[0045] In the above step one, prepare appropriate amount of distilled water, sodium alginate (SA), potassium persulfate (KPS), acrylamide (AM), caprolactam (CPL), lauryl dimethyl betaine (BS-12) And acetic acid (AcOH), standby;

[0046] In the above step two, first weigh 1.5 g of sodium alginate (SA) and slowly and evenly add it to the three-necked flask, then add an appropriate amount of distilled water and stir until the sodium alginate (SA) dissolves;

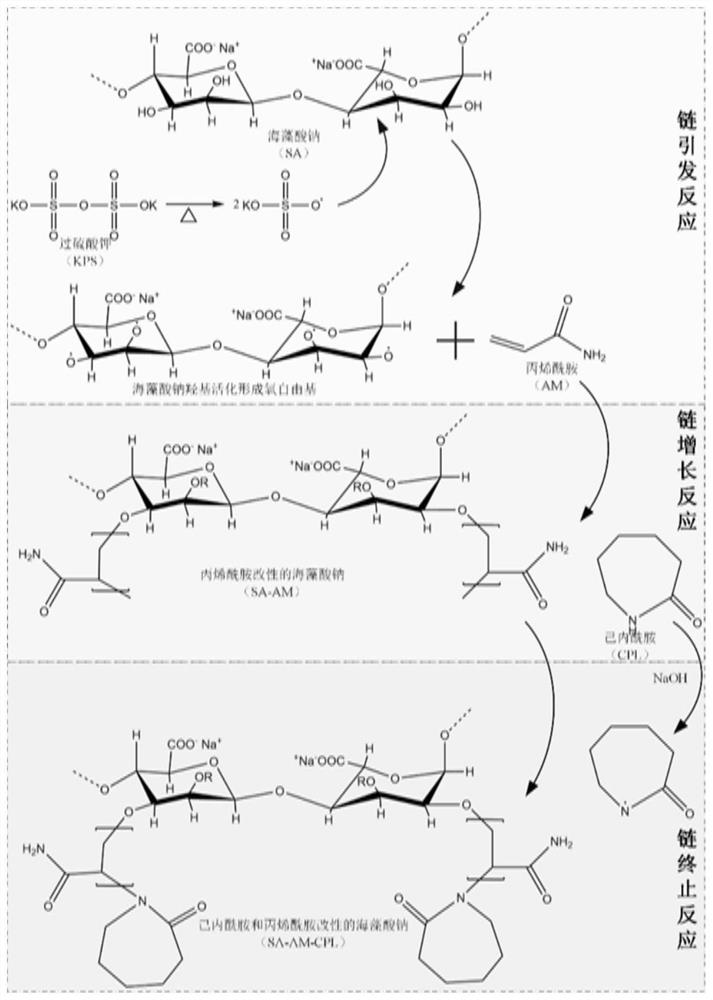

[0047] Wherein in above-mentioned step 3, at first regulating water temperature is 55 ℃, the sodium alginate (SA) solution in the there-necked flask is carried out water-bath heating, then in the sodium alginate (SA) solutio...

Embodiment 2~ Embodiment 25

[0051] Implementation content is the same as embodiment 1, and the addition amount of each raw material is by table 1.

[0052]

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com