Biological feed fermentation system with oxygen content adjusting function

A technology of biological feed and fermentation system, applied in the field of biological feed fermentation system, can solve the problems of low fermentation efficiency, untimely regulation of oxygen content, affecting the survival and fermentation of inoculum, etc., so as to improve fermentation efficiency and quality, and facilitate adjustment and switching operations. , to avoid the effect of temperature accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

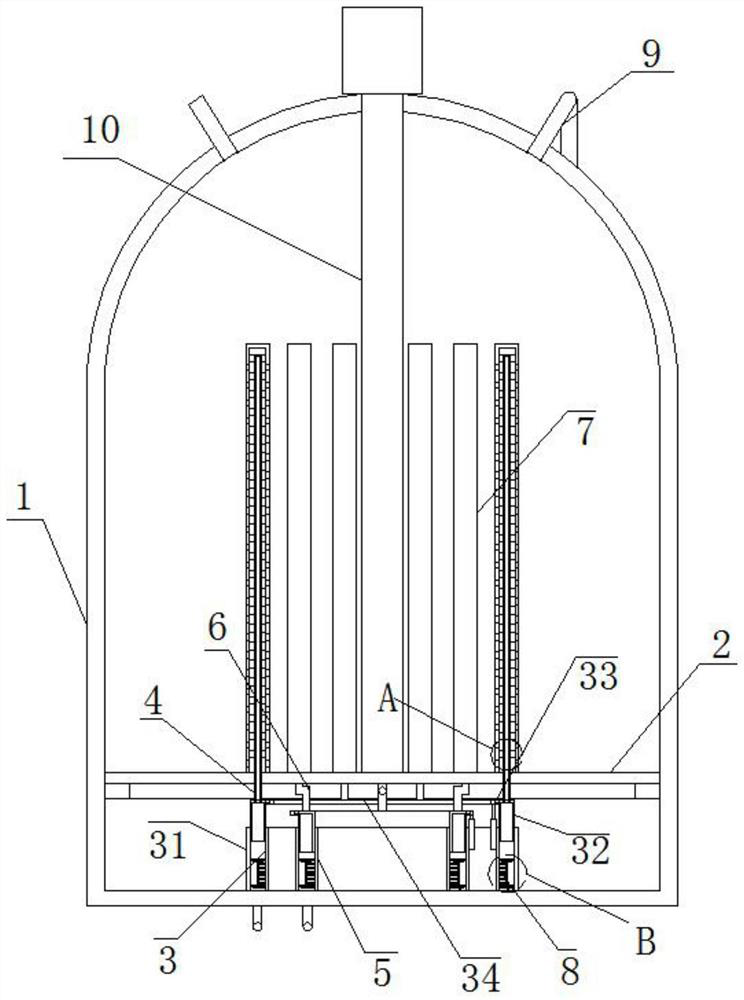

Embodiment 1

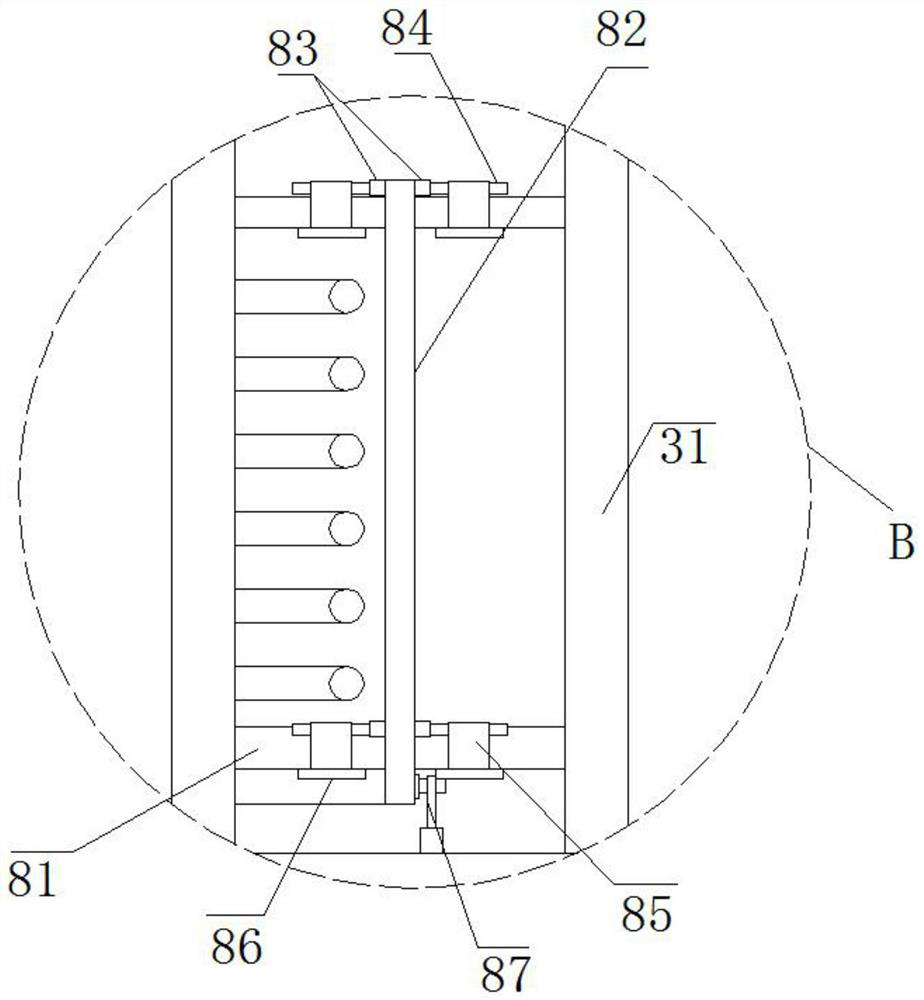

[0032]The bottom of the outer ring adjustment mechanism 3 is installed with a trachea 1 communicating with the fermenter 1, and the bottom of the inner ring adjustment mechanism 5 is installed with a trachea 2 connected with the fermenter 1. There are connecting pipe 1 and connecting pipe 2, and the end of the exhaust pipe 9 protruding from the fermentation tank 1 is connected with a vent pipe and connecting pipe 3, the connecting pipe 3 is connected with the connecting pipe 1, the connecting pipe 2 is connected with the intake pipe, and the connecting pipe 3 is connected Electromagnetic valves are installed on the connecting pipe two and the vent pipe.

Embodiment 2

[0034] A motor 2 is installed on the end of the rotating shaft 10 protruding from the top of the fermentation tank 1, a feeding pipe is installed on one side of the top of the fermentation tank 1, a discharge pipe is installed on one side of the top of the partition plate 2, and a push rod motor is used for the first pushing unit.

[0035] Working principle: when in use, the biological feed material to be fermented is put into the fermenter 1 from the feed pipe for fermentation, and the gas produced by fermentation is discharged along the exhaust pipe 9 during the fermentation process. The gas can be discharged to the external exhaust gas purification device through the vent pipe for purification, and at the same time, it can also flow back to the outer ring adjustment mechanism 3 or the inner ring adjustment mechanism 5 to the inside of the fermenter 1 through the connecting pipe three and the connecting pipe one. Internal circulation, on the one hand, can reduce the heat loss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com