Method for refining rare earth inclusions in steel through magnesium pretreatment

A pretreatment and inclusion technology, applied in the field of iron and steel metallurgy, can solve the problems of large size of rare earth inclusions, achieve the effects of reducing dissolved oxygen content, improving steel performance, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

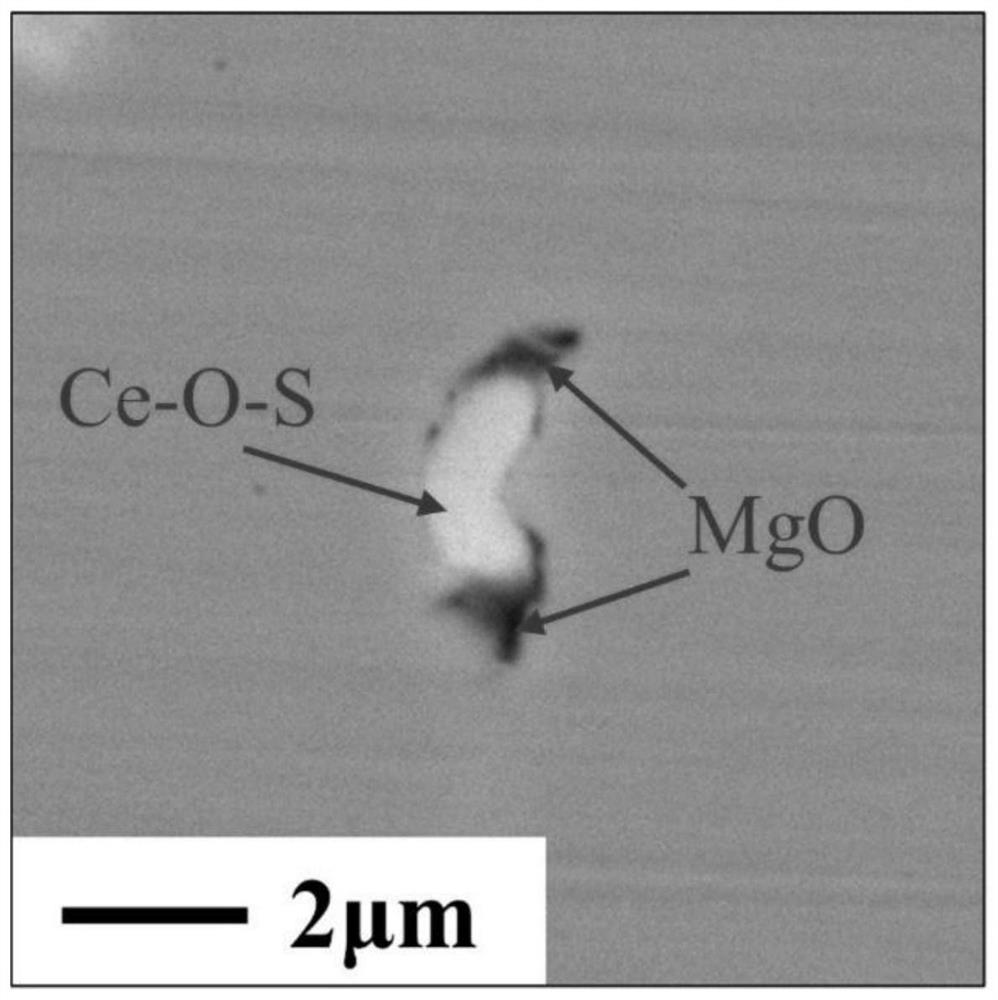

Image

Examples

Embodiment 1

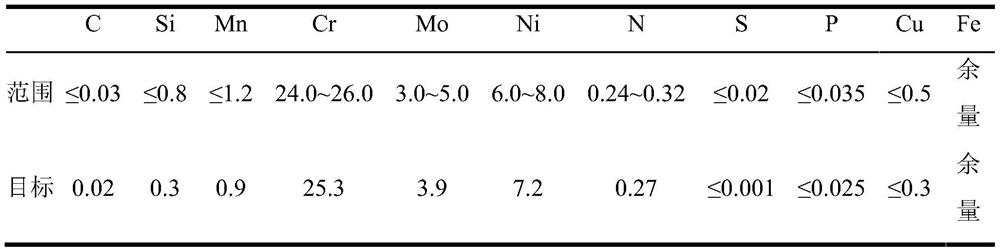

[0032] S32750 super duplex stainless steel is smelted by "EAF→AOD→LF→die casting" process, and LF is the last refining process. The amount of molten steel is 30t. The chemical composition of S32750 super duplex stainless steel is shown in Table 1.

[0033] Table 1S32750 super duplex stainless steel chemical composition (wt.%)

[0034]

[0035] This example provides a method for magnesium pretreatment to refine rare earth inclusions in steel. For S32750 super duplex stainless steel, the specific process flow is as follows:

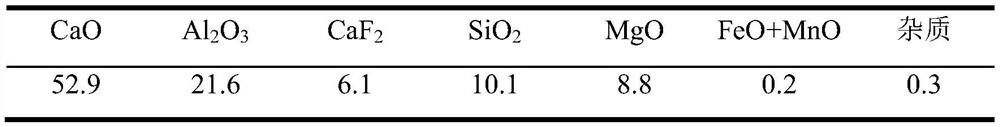

[0036] (1) EAF is used to melt S32750 super duplex stainless steel, and AOD is used to decarburize, desulfurize and alloy it. The above operations are all carried out according to conventional processes. After entering the LF station, the tempering and slag adjustment operations are carried out first. The composition of the refining slag is shown in Table 2, which meets the requirements of white slag refining. Afterwards, the aluminum deoxidation oper...

Embodiment 3

[0047] The process of "BOF→LF→RH→Continuous Casting" is used to smelt H13 die steel. RH is the last refining process, and the amount of molten steel is 120t. The chemical composition of H13 die steel is shown in Table 4.

[0048] Table 4H13 Die Steel Chemical Composition (wt.%)

[0049]

[0050] This embodiment provides a method for magnesium pretreatment to refine rare earth inclusions in steel. For H13 die steel, the specific process flow is as follows:

[0051] (1) BOF is used to decarburize and alloy H13 steel, and LF is used to adjust the temperature, slag and aluminum deoxidation of H13 steel. The above operations are all carried out according to the conventional process. Among them, after the aluminum deoxidation operation, the bottom blowing argon flow rate was adjusted to 1.5NL / (min·t), and soft blowing was performed at this argon flow rate for 15 minutes. Table 5 shows the composition of LF refining slag, which meets the requirements of white slag refining. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com