Welding bead residual stress eliminating device and method

A residual stress and weld bead technology, applied in the field of weld bead residual stress relief devices, can solve the problem of inability to eliminate multiple weld bead stress, and achieve the effects of eliminating residual stress, eliminating high efficiency and improving speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

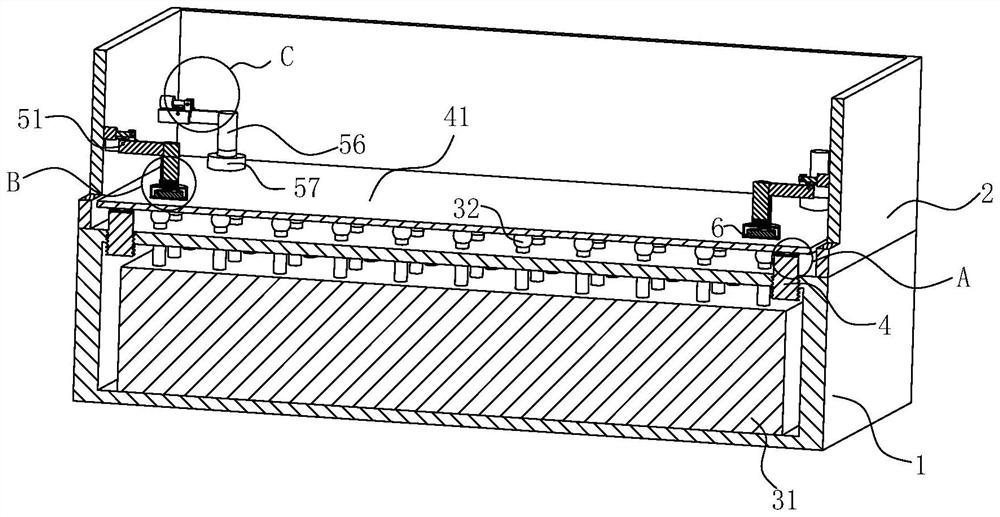

[0040] As an embodiment of the present invention, the pressing unit includes:

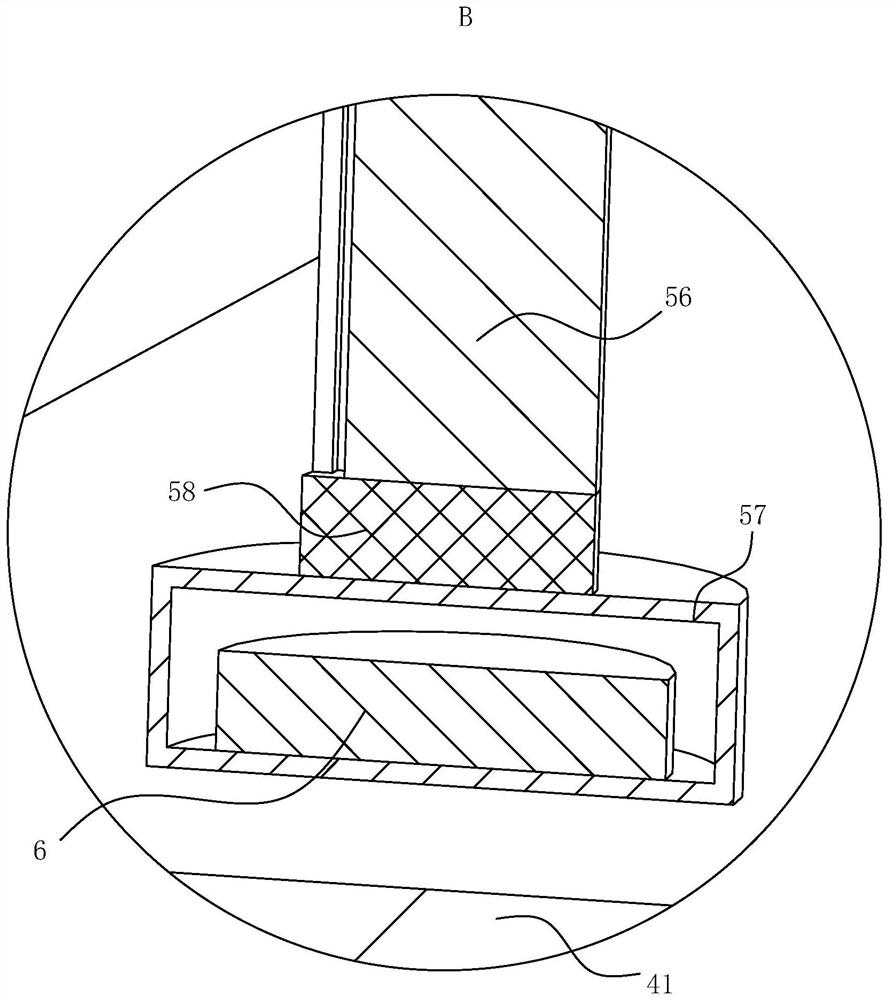

[0041] Compression bracket 51, described compression bracket 51 is fixedly installed on the inner wall of described housing 2, on described compression bracket 51, rotating block 54 and slide bar 55 are respectively installed in rotation, and described slide bar 55 and described rotation The lower end of the block 54 is fixedly connected, and a compression rod 56 is slidably installed on the slide bar 55, and a compression block 57 is fixedly installed at the lower end of the compression rod 56, and a resonator 6 is fixedly installed in the compression block 57;

[0042] Cylinder 52, the cylinder 52 is fixedly installed on the inner wall of the housing 2, a push rod 53 is slidably installed in the cylinder 52, and the other end of the push rod 53 is rotatably mounted on the rotating block 54;

[0043] During work, start the cylinder 52, make the push rod 53 move backward, drive the rotating block 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com