Hydraulic brake caliper

A technology of hydraulic brakes and brake calipers, applied in the direction of brake actuators, gear shifting mechanisms, mechanical equipment, etc., can solve the problems of affecting the braking force of disc brakes, easy residual gas, etc., to improve the braking force of disc brakes, not easy to damage , the effect of preventing brake failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

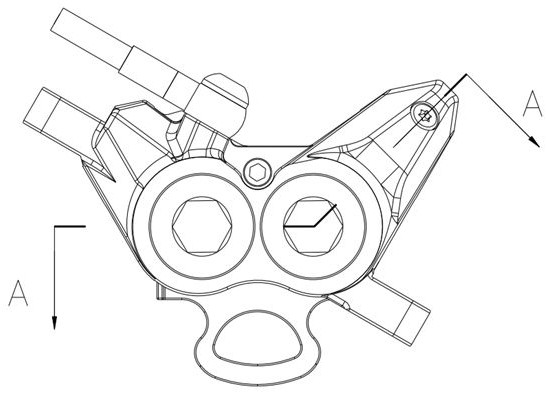

[0033] The following describes the technical solution of the present application in detail with reference to the drawings, the purpose of which is to help those skilled in the art understand the technical solution of the present application, and is not intended to limit the scope of protection. The horizontal height referred to in this application refers to the relative horizontal height when the hydraulic brake caliper is assembled on the vehicle.

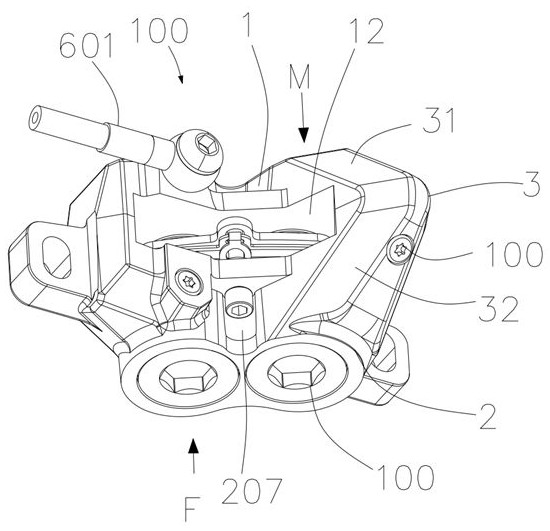

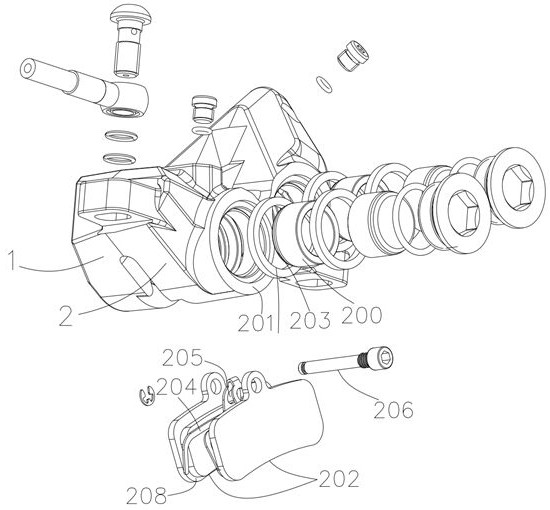

[0034] refer to figure 1 and figure 2 The hydraulic brake caliper 100 shown is a schematic diagram of the whole structure and a schematic diagram of an exploded structure. The main body of the brake caliper has an integrated structure, which can be completed by casting, CNC and other integrated processes.

[0035] Compared with the prior art, the integrated process has higher strength and can bear stronger braking force, while keeping the structure of the brake caliper 100 from being damaged. The main body of the brake caliper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com