Powder detonation engine conveying system and method

A conveying system and engine technology, applied in the field of powder detonation engine conveying system, can solve the problem of low detonation wave energy, and achieve the effect of easy engineering application and realization of engineering application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

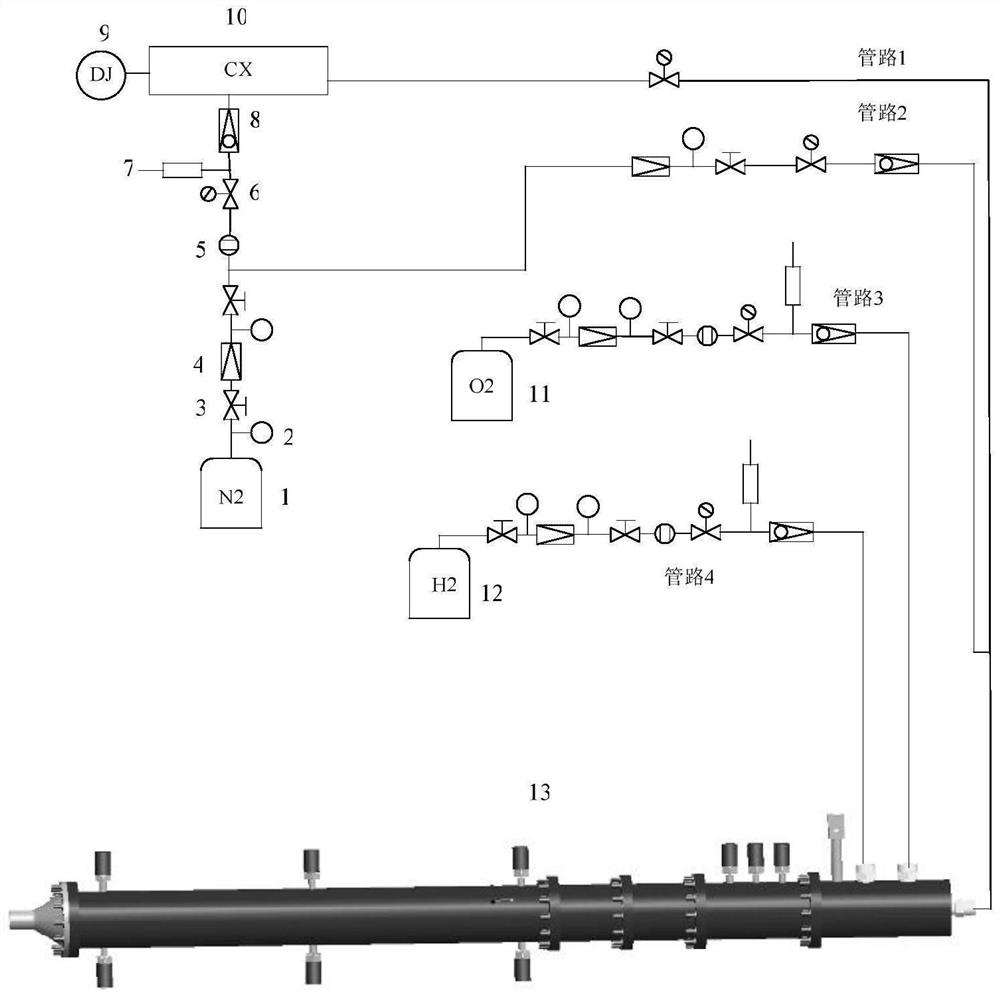

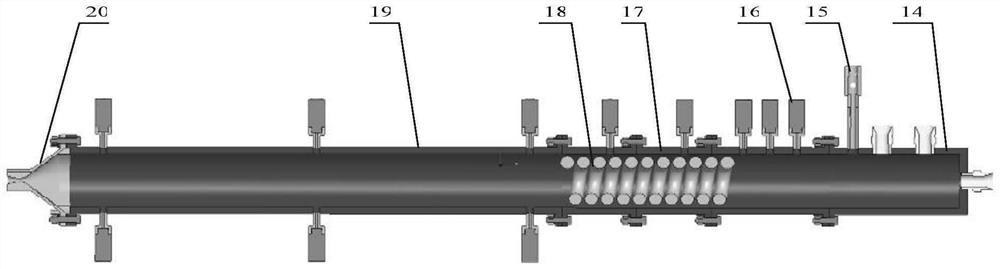

[0028] The present invention uses nitrogen as the fluidizing gas to transport the aluminum powder to the detonation engine, and at the same time, quantitatively transports oxygen and hydrogen to the detonation engine through the delivery system. In order to realize the precise delivery of aluminum powder, oxygen and hydrogen, different way of delivery. For aluminum powder, nitrogen is used as the fluidizing gas and the conveying method is driven by a motor. The precise delivery of oxygen and hydrogen can be controlled by a pressure reducing valve and a solenoid valve. Sensors with different functions are placed in the precise control system for real-time monitoring. The detonation engine consists of a pre-explosion tube, a mixing tube, a spiral tube, a test tube and a nozzle, and the parts are connected by flange bolts.

[0029] In order to make the purpose, features and advantages of the technical solution proposed by the present invention more obvious and understandable, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com