Settlement characteristic evaluation method of battery slurry

A technology of sedimentation characteristics and slurry, applied in the direction of analyzing materials, instruments, etc., to achieve the effect of speeding up production and research and development progress, monitoring quality stability, and avoiding waste of time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

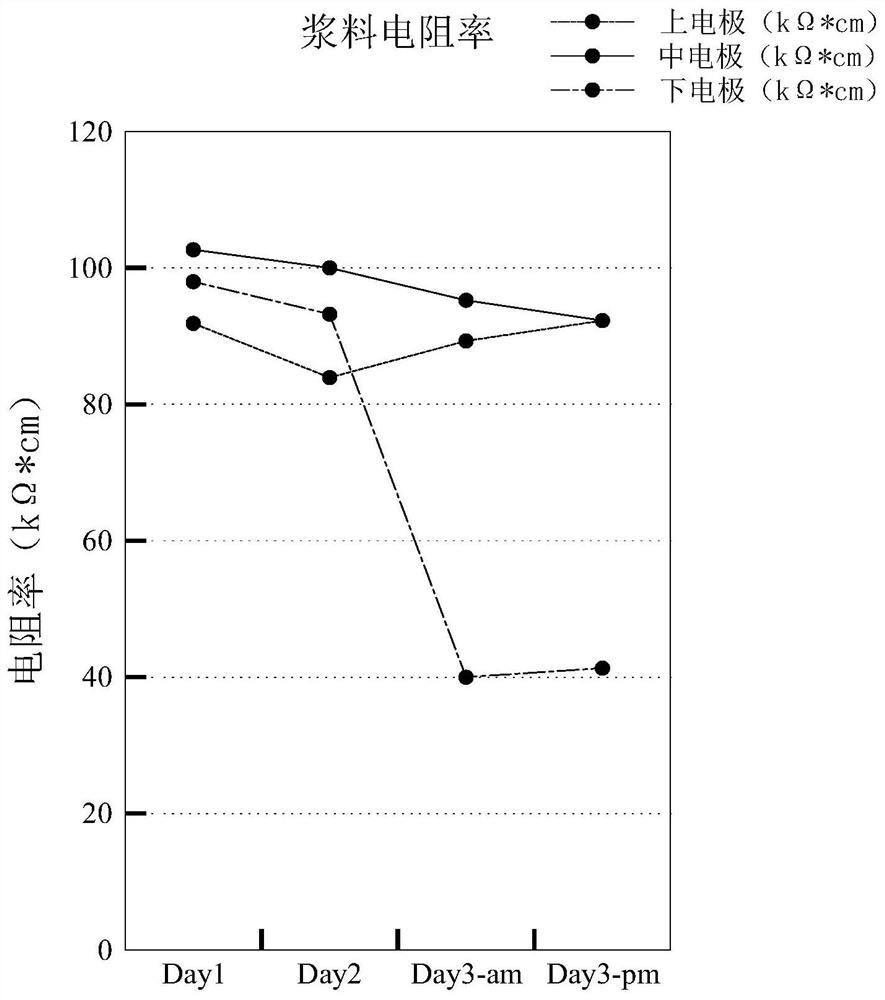

[0017] According to the present invention, the conductivity parameter of the battery slurry has a significant correlation with factors such as the formula of the battery slurry, the type and content of the conductive agent, the type and content of the binder, and the battery slurry is left to stand for a period of time after the stirring is completed. Gel settlement may occur, and at this time, the conductivity values of different layers of the battery slurry will also show varying degrees of change. Therefore, the resistivity change at different positions of the battery slurry can be monitored in real time, and the resistivity of the battery slurry can be used to characterize the sedimentation characteristics of the battery slurry more comprehensively.

[0018] The invention is a method for evaluating the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com