Embedded cabinet circulating temperature control system and use method

A temperature control system and embedded technology, applied in the direction of control/adjustment system, non-electric variable control, and simultaneous control of multiple variables, etc., can solve problems such as lack of recycling capacity of waste heat resources, pollution of circuit equipment, and influence on temperature adjustment efficiency , to improve work efficiency and temperature regulation effect, reduce temperature regulation energy consumption, and improve cleaning and purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate the implementation of the technical means, creative features, goals and effects achieved by the present invention, the present invention will be further elaborated below in conjunction with specific embodiments.

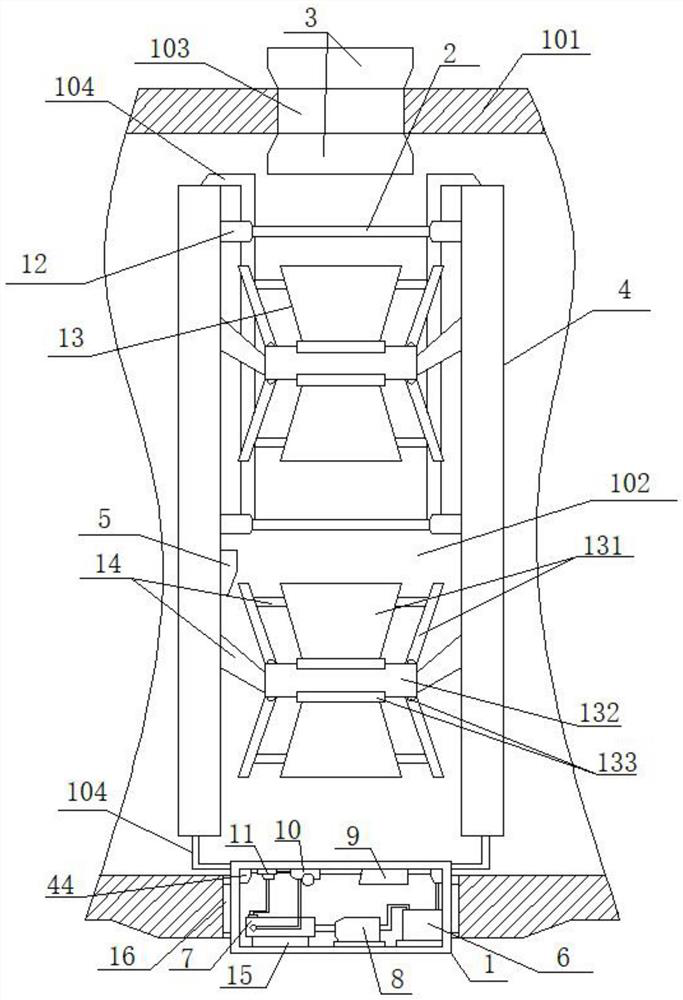

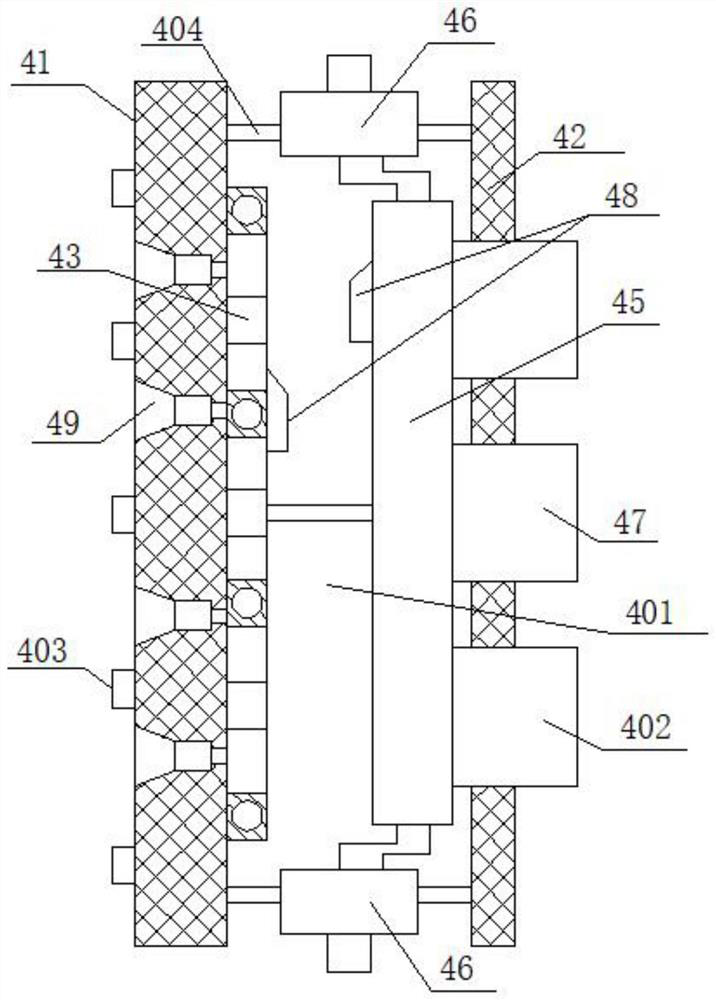

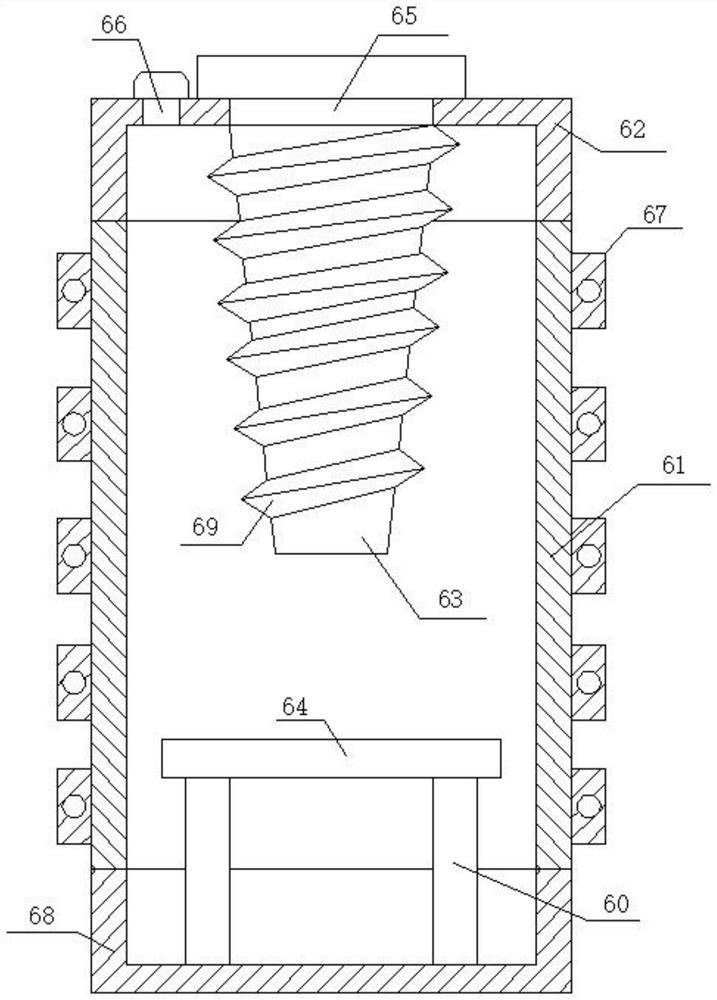

[0029] Such as figure 1 As shown in —4, an embedded cabinet circulation temperature control system includes a load base 1, a heat exchange tube 2, a drainage fan 3, a flow guide heat exchange plate 4, a temperature and humidity sensor 5, an air filter 6, and an air vortex tube 7 , a booster fan 8 and a drive circuit 9, two flow guide heat exchange plates 4, embedded in the cabinet 1, symmetrically distributed on both sides of the axis of the cabinet 101 and connected to the inner side of the cabinet 101, the two flow guide heat exchange plates 4 The surface is distributed parallel to the axis of the cabinet 101, and the two guide heat exchange plates 4 form a cooling cavity 102 coaxially distributed with the cabinet 101. The top and bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com