Cascade convolutional neural network-based automatic detection method for welding seam of steel part

A convolutional neural network, automatic detection technology, applied in biological neural network models, neural architectures, computer components, etc., can solve the problem of low welding seam detection accuracy, achieve good noise suppression ability, accurate laser stripe boundaries, improve The effect of anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The specific embodiments described here are only used to explain the technical solution of the present invention, and are not limited to the present invention.

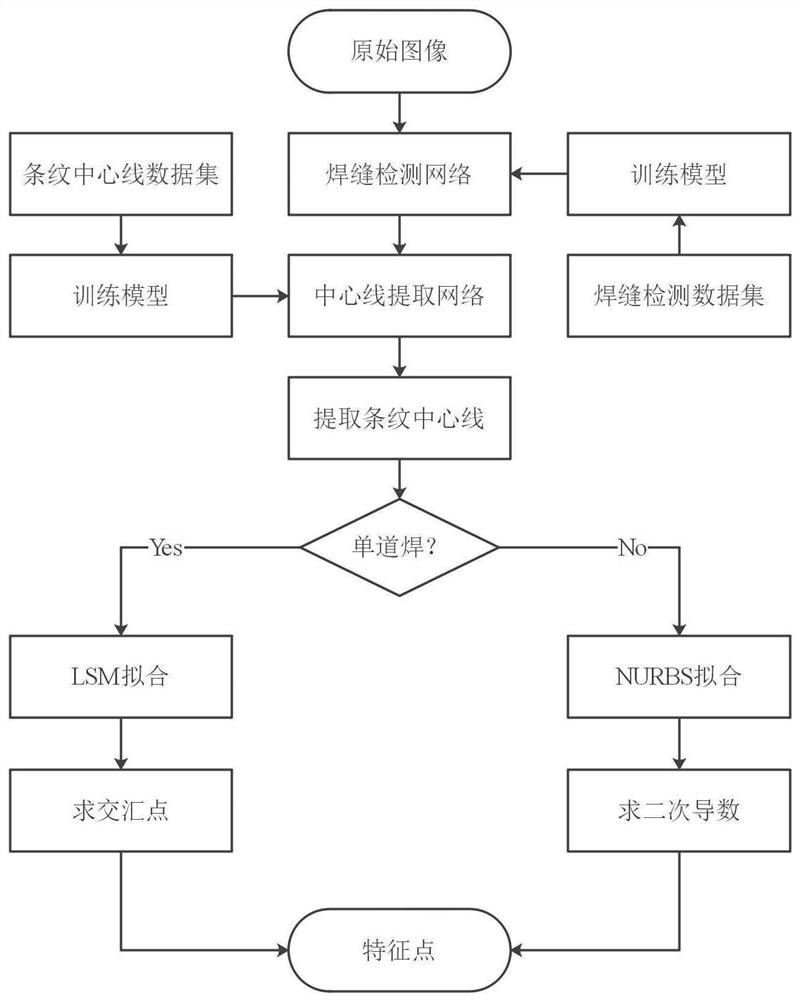

[0048] An automatic detection method for steel welds based on cascaded convolutional neural networks, such as figure 1 shown, including the following steps:

[0049] Step S1, obtaining weld seam data, using an industrial camera and an infrared laser line to scan the steel piece to obtain weld seam data;

[0050] Step S2, data labeling, mark the weld area and centerline on the image, and complete the production of the weld reference image set and the centerline reference image set;

[0051] Step S2 specifically includes:

[0052] Step S2-1, converting the weld seam digital image into P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com